A kind of PES-based flexible white fluorescent polyester and preparation method thereof

A blue fluorescent, HO-PES-OH technology, applied in the field of PES-based flexible white fluorescent polyester and its preparation, can solve the problems of color change of emitted light, poor miscibility, uneven fluorescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

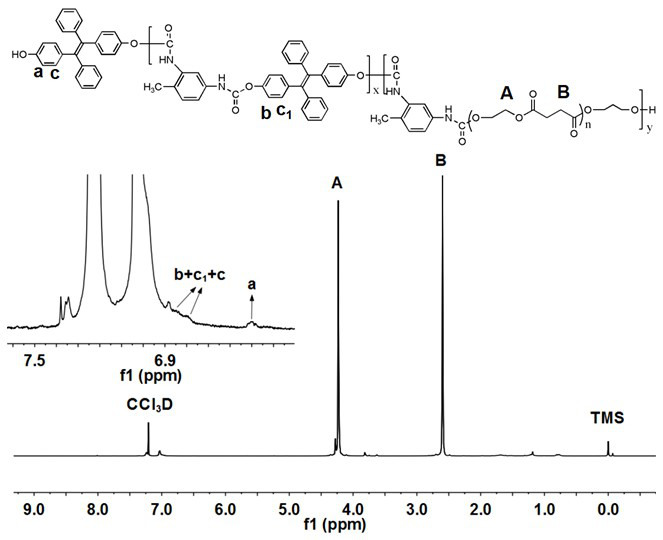

[0051] Example 1: Blue fluorescent donor unit PES- co - Preparation of TPE:

[0052] First, add 50g of HO-PES-OH prepolymer, 0.5g of bishydroxytetraphenylethylene (TPE-2OH), and 1.8g of TDI into the reactor under an inert gas environment. Next, raise the temperature until all the solids are melted, then lower the temperature to 160°C, and continue the reaction for 1~2h. Nitrogen protection discharge to get PES- co -TPE.

[0053] Synthetic PES- co -TPE copolyester products have the following properties: 1) Intrinsic viscosity [ŋ]=0.88 g / dL; 2) Under the excitation of 365nm ultraviolet light, the peak emission wavelength of strong blue fluorescence is 472nm; 3) The melting point is 99°C; 4 ) The absolute quantum yield of fluorescence at room temperature is 85.1%.

Embodiment 2

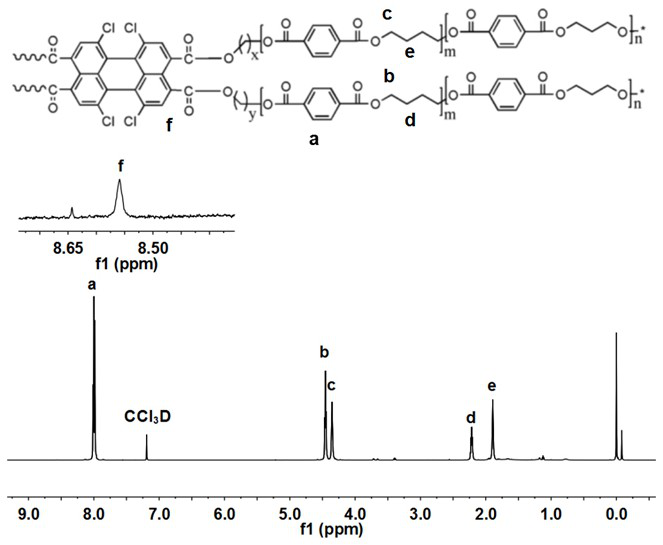

[0054] Example 2: Orange Fluorescent Acceptor Unit PES- co - Preparation of TPE:

[0055] Preparation of PTBT by a two-step melt polycondensation method- co -TDAT. First, add 19.4g of dimethyl terephthalate, 7.6g of propylene glycol, 9.0g of butanediol and 1.0g of tetrachloroperylene anhydride into the reactor, the catalyst is tetrabutyl titanate, the mass is 0.06g, and the inert gas environment . Next, raise the temperature until all the solids are melted, then gradually raise the temperature to 250°C, compress and polymerize under reduced pressure for 3 hours, and discharge the material under nitrogen protection to obtain PTBT- co -TDAT.

[0056] Synthetic PES- co -TPE copolyester products have the following properties: 1) Intrinsic viscosity [ŋ]=1.03 g / dL; 2) Under the excitation of 365nm ultraviolet light, the emission peak of strong orange fluorescence is 580nm; 3) The melting point is 154°C; 4) The absolute quantum yield of fluorescence at room temperature is 86.9%...

Embodiment 3

[0057] Embodiment 3: Preparation of white flexible blended polyester material

[0058] First, the above-prepared PES- co -TPE 10g and PTBT- co - Dissolve 0.8g of TDAT in dichloromethane, and then spin-dry using a rotary evaporator at 35°C; finally, fully mix the solid mixture through an extruder at 110~120°C to obtain PES- co -TPE / PTBT- co - TDAT blend.

[0059] The prepared blended polyester material has the following properties: 1) The appearance is orange-red; 2) It emits strong white fluorescence under the excitation of 365nm ultraviolet light; 3) At room temperature, the absolute quantum yield of fluorescence under the excitation of 340nm ultraviolet light is about 34.9% ;4) The 0.2mm film is flexible and bendable; 5) It has strong plasticity and can be made into many shapes; 6) It has two melting points, 99°C and 154°C.

[0060] Structural characterization: using the AvIII nuclear magnetic resonance spectrometer of Bruker, Switzerland, deuterated chloroform (CDCl 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com