Preparation method and application of biomass porous carbon for supercapacitor

A supercapacitor, biomass technology, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of low content of doping atoms, irregular pore structure, small specific surface area, etc., to achieve large specific surface area, The effect of good pore structure, simple preparation method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

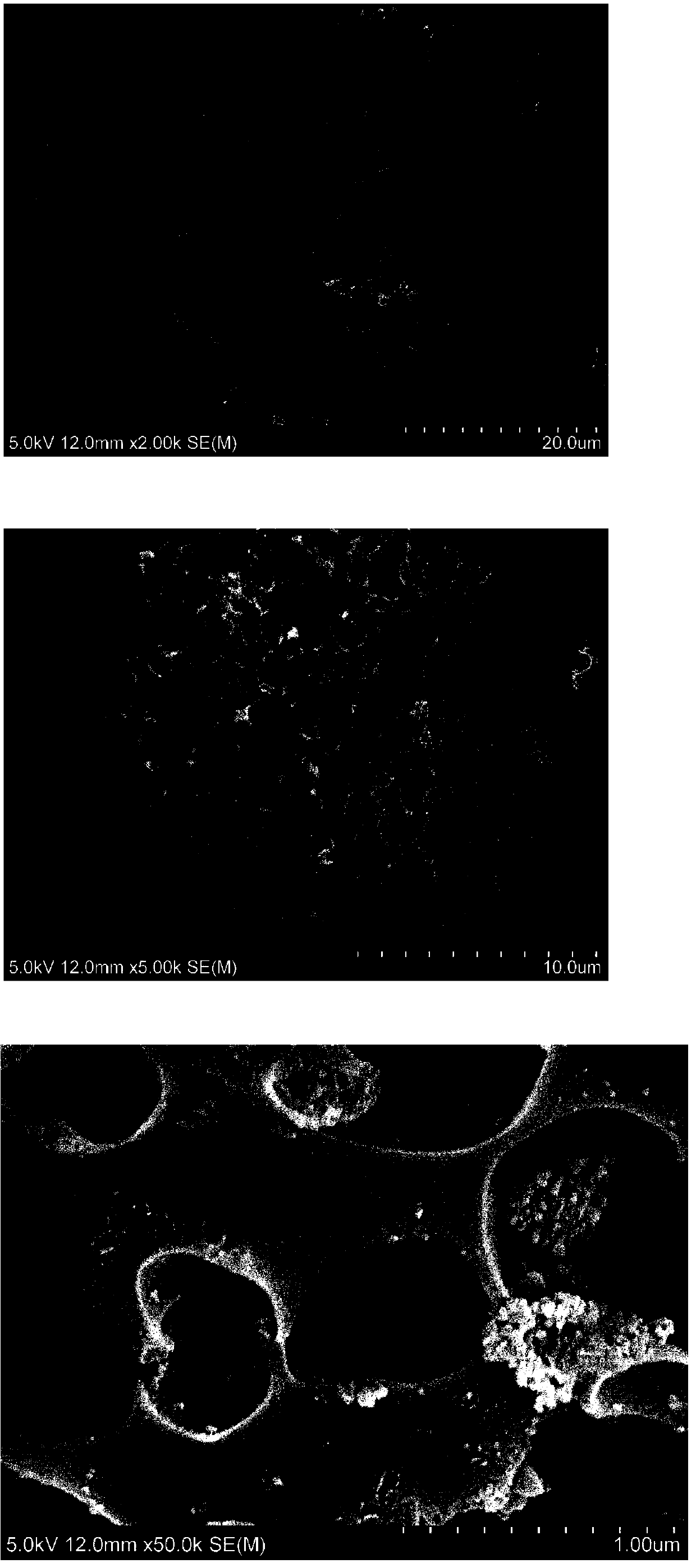

[0035] (1) Crushing the Luo Han Guo shell into fine particles, passing through a 200-mesh filter, placing it in a blast drying oven, and drying at 90°C;

[0036](2) Mix the above-mentioned Luo Han Guo shell sample with KOH and urea in a certain mass ratio, add distilled water and stir evenly, and dry the mixture completely at 105°C;

[0037] (3) Using a tube furnace, under the protection of argon, heat-treat the dried sample at 800°C for 2h at a heating rate of 2°C / min, and naturally cool to room temperature to obtain a black product;

[0038] (4) The product was washed several times with 2M HCl to remove impurities, and then washed with distilled water until neutral pH=7. The cleaned sample was vacuum-dried at 100° C. to obtain the target product, biomass porous carbon for supercapacitors.

[0039] Among them, the mass ratio of Luo Han Guo shell sample to KOH and urea is 1:1:1.5, respectively.

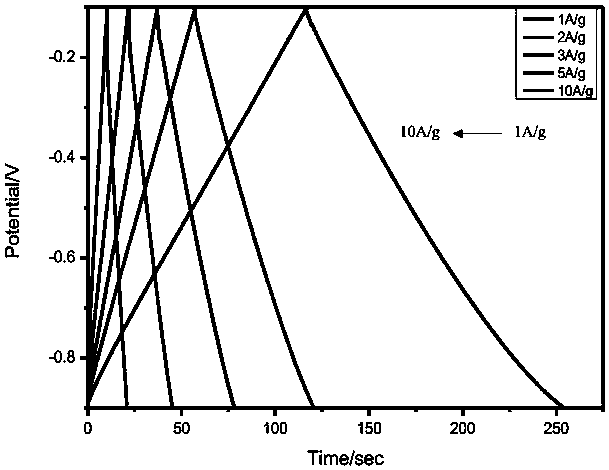

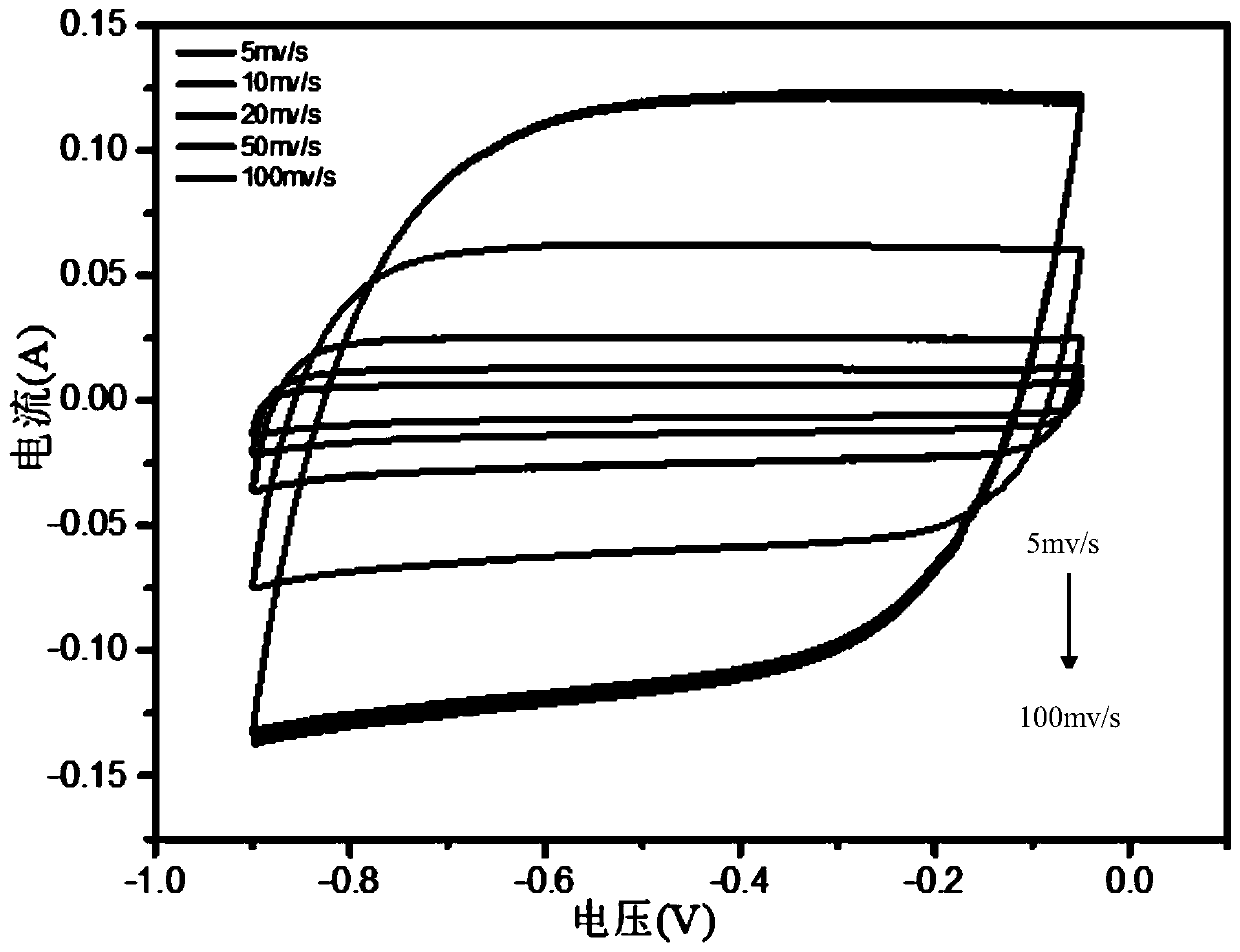

[0040] The supercapacitor obtained in Example 1 was tested with biomass porous ...

Embodiment 2

[0043] Repeat the steps of Example 1, and only change the mass ratio of Luo Han Guo shell sample to KOH and urea in step (2) to be 1:1.5:1.

Embodiment 3

[0045] Repeat the steps of Example 1, and only change the mass ratio of Luo Han Guo shell sample to KOH and urea in step (2) to be 1:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com