A method for slope ecological restoration

An ecological restoration and slope technology, applied in the fields of botanical equipment and methods, excavation, sowing, etc., can solve the problems of being susceptible to hydraulic erosion, freezing and thawing erosion in winter, rapid leaching of nutrient elements, and aggravating the hardening state. Plant long-term growth needs, slowing down the leaching of nutrients, reducing the effect of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

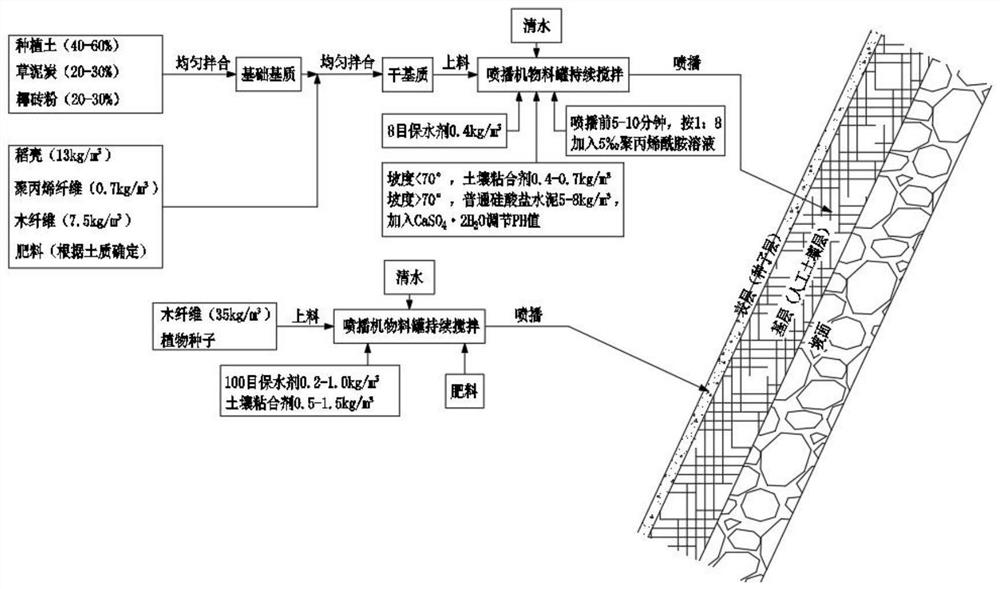

Method used

Image

Examples

Embodiment 1

[0039] On a road slope in a mountainous area, the embankment and cutting slopes are 50-60°, all of which are soil slopes, mainly sandy loam, and the measured pH value is 5.5-6.0. The altitude of the project area is 1100m, the average annual precipitation is 1150mm, the annual average temperature is 15.1℃, the extreme low temperature is ~7.1℃, the extreme high temperature is 37.8℃, the frost-free period is 234 days, and the sunshine hours are 1000h.

[0040] The project is a soil slope with good soil quality, no need to spray the base layer, and directly spray the surface layer. According to the high altitude of the project area and the characteristics of long freezing time in winter, a mixture of perennial ryegrass, tall fescue, purple fescue and bluegrass was used for sowing. at 10m 3 First add 3m 3 Clear water, add 264kg wood fiber and 28kg mixed seeds, keep stirring, add water to 8m 3 In the process of adding water, add 2kg of water-retaining agent and 3.2kg of binder, a...

Embodiment 2

[0043] A wind farm in Southwest China excavated a side slope with a slope of 70° and moderately weathered sand and shale. The altitude of the project area is 900m, the average annual rainfall is 1120mm, the annual average temperature is 16.8°C, the extreme low temperature is ~7.9°C, the extreme high temperature is 43°C, the frost-free period is 294 days, and the sunshine hours are 1200h.

[0044] First of all, clear the pine and dangerous rocks on the slope surface, trim the chamfering of the slope, and make the slope surface as smooth as possible. The vertical slope is drilled at a distance of 2m, and the main anchor is inserted and grouted for protection. The main anchor uses a ribbed steel bar with a diameter of 18mm, and the depth of penetration into the rock is 70cm. Drill holes between the main anchors and interpolate secondary anchors. The density is controlled by interpolating 1 to 2 secondary anchors between each two main anchors. The secondary anchors use smooth roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com