A Heat Transfer Element for Thinning Liquid Film Thickness of Regenerative Condensing Heat Exchanger

A technology of condensing heat exchanger and liquid film thickness, which is applied in the direction of laminated components, heat transfer modification, air heater, etc., can solve the problem of no matching heat transfer components, etc., and achieve faster drainage rate and thinner thickness , The effect of increasing the drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

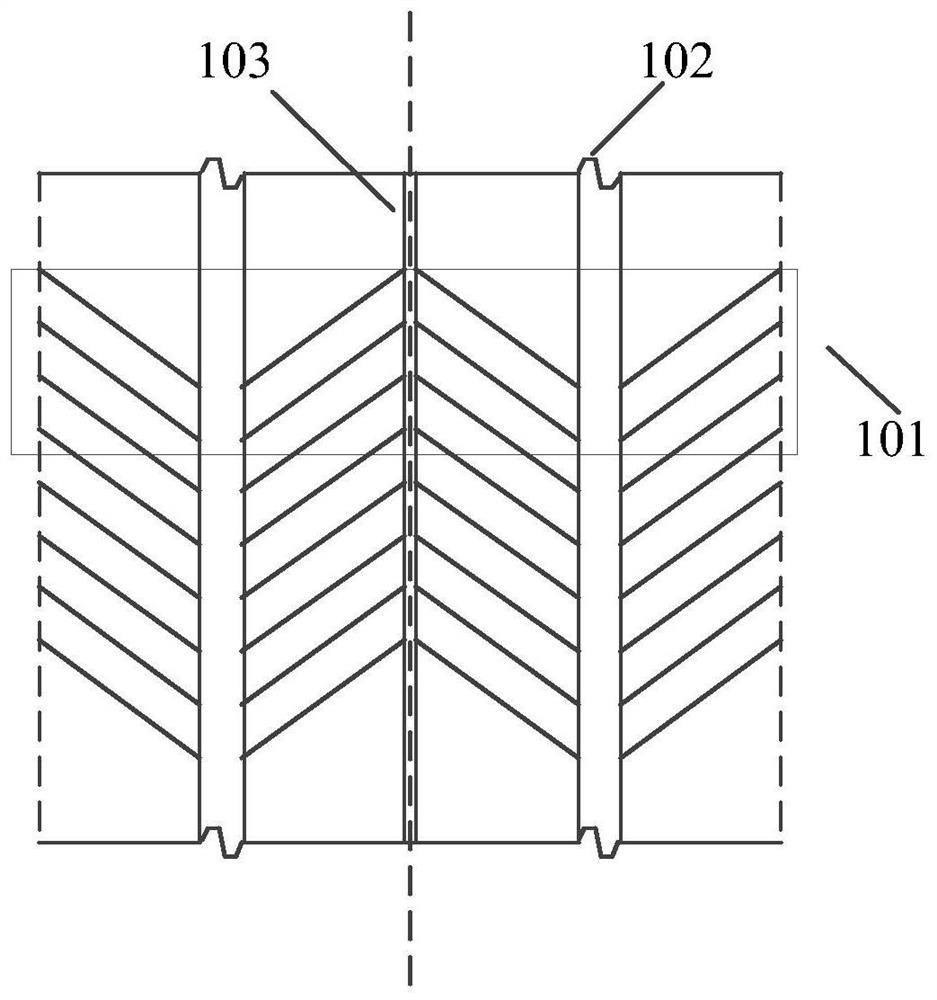

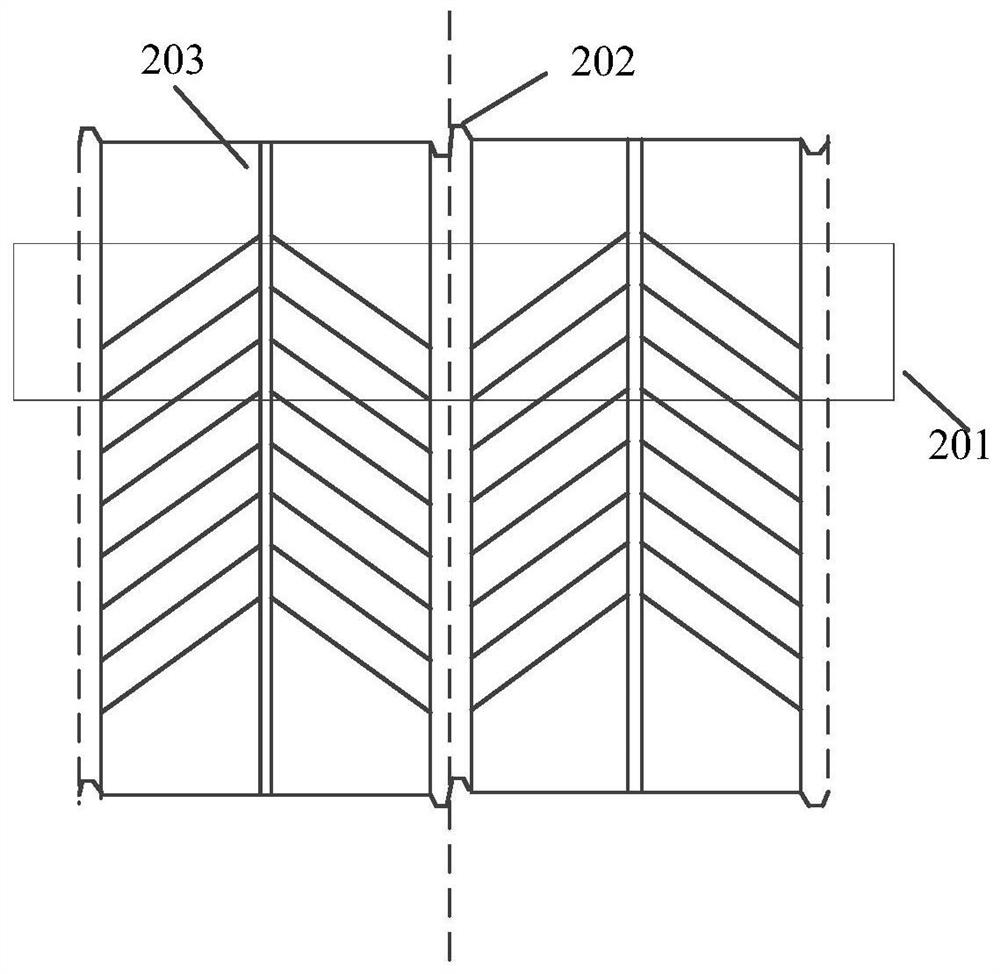

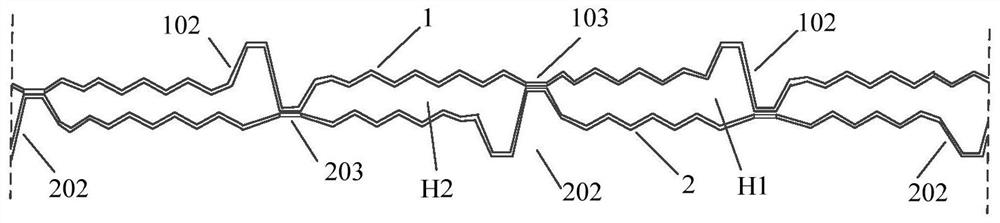

[0039] Such as Figure 1 to Figure 3 As shown, the present invention provides a heat transfer element for thinning the liquid film thickness of a regenerative condensing heat exchanger, including a first corrugated plate 1 and a second corrugated plate 2, such as figure 1 and figure 2 shown. The first corrugated plate 1 is composed of a series of inverted double herringbone corrugated channels 101 with a corrugation inclination of 30° to 50°, and a first vertical channel with a single crest and a single trough is added at the symmetry of the inverted single herringbone corrugated channel. The trapezoidal corrugated channel 102 and the first vertical plate 103 are added at the junction of two adjacent inverted double herringbone corrugated channels. The wave height of the first vertical trapezoidal corrugated channel 102 is 10 mm to 25 mm, the width of the first ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com