Alumina support, preparation method therefor, catalyst, preparation method therefor and method for lowering content of dialkene in hydrocarbon oil

An alumina carrier and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problem of arsenic resistance, poor colloid resistance, and insufficient hydrogenation activity. Ideal, not fully utilized and other problems, to achieve the effect of improving catalytic activity, low monoolefin saturation rate, and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]According to the preparation method of the present invention, introducing an anionic surfactant into the slurry can effectively improve the pore volume, pore size distribution concentration and specific surface area of the final prepared alumina carrier, and can further improve the mechanical properties of the final prepared alumina carrier. strength.

[0040] According to the preparation method of the present invention, the anionic surfactant is phosphoric acid ester and / or dithiophosphoric acid ester.

[0041] The phosphoric acid ester is the phosphoric acid ester shown in formula I,

[0042]

[0043] In formula I, R 1 for C 8 -C 16 Alkyl groups, specific examples of which may include, but are not limited to: octyl, nonyl, decyl, undecyl, dodecyl, tridecyl, tetradecyl, pentadecyl and hexadecyl base. Preferably, R 1 for C 10 -C 14 of alkyl.

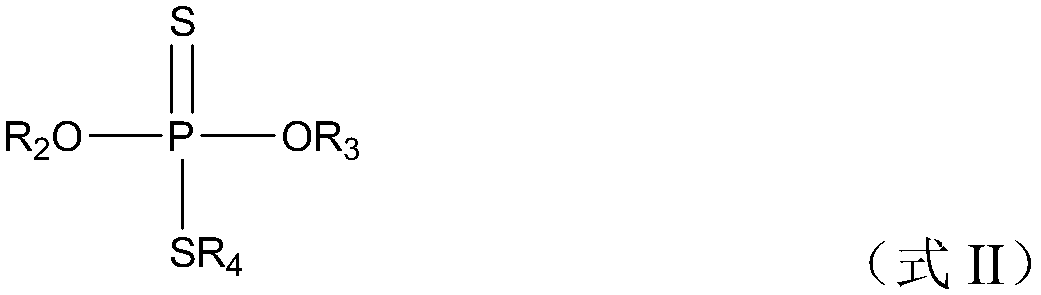

[0044] The phosphorodithioate is a phosphorodithioate shown in formula II,

[0045]

[0046] In formula II, R ...

Embodiment 1

[0118] With 100g macroporous aluminum hydroxide powder (purchased from Sinopec Changling Catalyst Factory, the ratio of pores with a pore diameter of 10-50nm to the total pores is 65%) and 1.5g scallop powder (purchased from Henan Lankao County Vegetable Gum Factory), 3.0g ethyl cellulose (purchased from Sinopharm Chemical Reagent Co., Ltd.) and 4.0g sodium polyacrylate (purchased from Sinopharm Chemical Reagent Co., Ltd.) were mixed and stirred for 20 minutes, and 3.0mL concentration of 60% by weight of concentrated nitric acid, 5.0 g lauryl phosphate monoester, 11.8 g of magnesium nitrate and 15 mL of deionized water were kneaded for 20 minutes to obtain a slurry. The obtained slurry is fed into an extruder through a die with an inner diameter of 1.5 mm for extrusion molding, and cut into a length of 3-8 mm to obtain a molded product. After the molded product was left at room temperature (25°C) for 40 minutes, it was dried at 120°C for 2 hours in an air atmosphere, and then ...

Embodiment 2

[0134] With 100g macroporous aluminum hydroxide powder (purchased from Changling Catalyst Factory of Sinopec, the ratio of pores with a pore diameter of 10-50nm to the total pores is 75%) and 1.6g of scallop powder (purchased from Henan Lankao County Vegetable Gum Factory) and A mixture of stearic acid at a mass ratio of 1:1, 2.5 g of a mixture of ethyl cellulose (purchased from Sinopharm Chemical Reagent Co., Ltd.) and hydroxyethyl cellulose at a mass ratio of 1:1, and 2.0 g of polystyrene Vinyl alcohol (purchased from Sinopharm Chemical Reagent Co., Ltd.) was mixed and stirred for 30 minutes, and 3.0 mL of 30% by weight aqueous acetic acid solution, 3.5 g of butyl octyl phosphorodithioate, 9.9 g of magnesium acetate and 15 mL of deionized water were added. Kneading was continued for 40 minutes to obtain a slurry. The obtained slurry is fed into an extruder through a die with an inner diameter of 1.5 mm for extrusion molding, and cut into a length of 3-8 mm to obtain a molded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com