Circular ring neodymium iron boron processing method

A processing method and NdFeB technology are applied in the processing field of circular NdFeB, which can solve the problems of low processing precision, cumbersome processing procedures, environmental pollution, etc., meet the requirements of simple operation, ensure processing dimensional accuracy, and realize feasibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

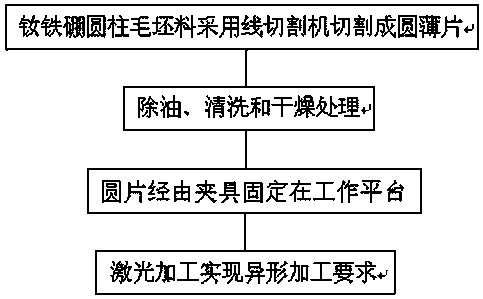

[0030] Such as figure 2 Shown, a kind of processing method of circular neodymium iron boron, comprises the following steps:

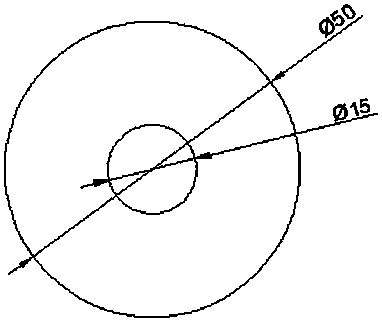

[0031] The first step is to fix the sintered NdFeB cylindrical blank so that the cutting surface is perpendicular to the horizontal plane, and use a wire electric discharge machine to cut the cylindrical blank into discs with a diameter of 50mm and a thickness of 2-5mm;

[0032] The second step is to degrease, clean and dry the disc in the first step;

[0033] The third step is to fix the wafer dried in the second step on the cutting table with a clamp;

[0034] The fourth step is to use the pulsed laser emitted by the laser cutting machine to radiate to the surface of the wafer material to achieve cutting. During the cutting process, nitrogen is selected as the auxiliary gas.

[0035] Process sintered NdFeB blanks into discs, such as figure 1 As shown, because of its own crystal structure, it forms inherent characteristics such as hard and brittle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com