Thermally-conductive far-infrared synergistic non-stick coating and preparation method thereof

A non-stick coating, far-infrared technology, used in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of thermal resistance, slow thermal conductivity, uneven heating of coatings, and achieve good thermal stability, improved palatability, long-lasting The effect of economic longevity and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

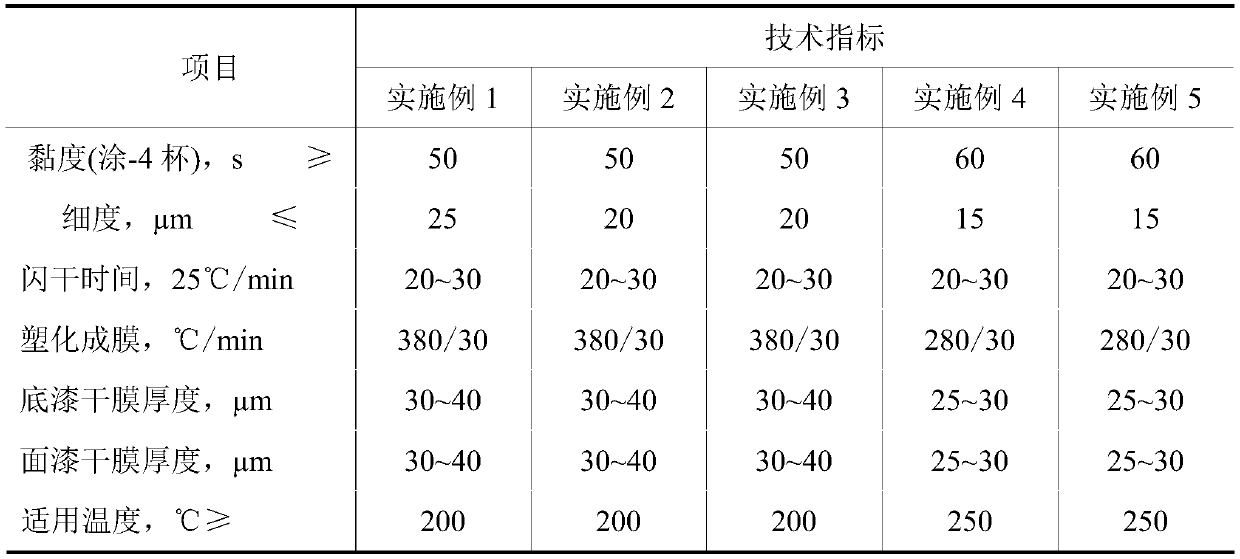

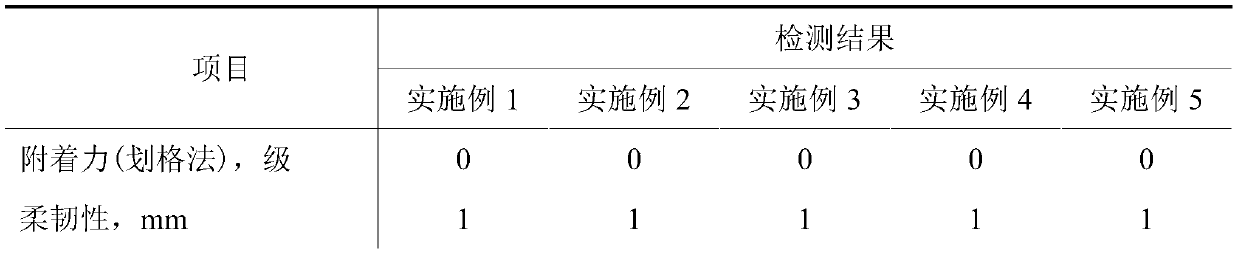

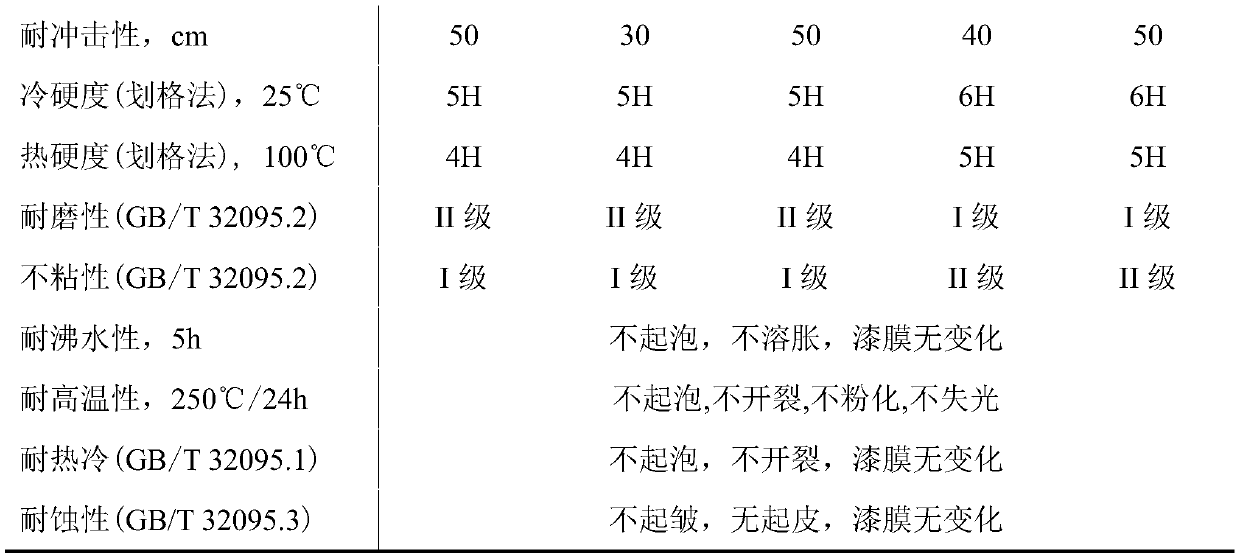

Embodiment 1

[0024] Example 1 General primer for heat conduction synergistic coating of electric heating kitchen utensils

[0025] Example 1 of the present invention consists of the following raw materials in parts by mass (wt%): 50 parts of D-100 water-based ceramic resin, 10 parts of PPS micropowder, 5 parts of BMI micropowder, 3 parts of pigment carbon black, 5% graphene-containing dispersion slurry 25 parts, ZX-Y far-infrared ceramic powder 5 parts, BYK-180 wetting and dispersing agent 0.5 parts, BD-3062 defoamer 0.25 parts, BD-2051 leveling agent 0.25 parts, Pangel S9 hydrated magnesium silicate 0.5 parts, 0.5 part of Degussa's A200 fumed silica.

Embodiment 2

[0026] Embodiment 2 Electric rice cooker liner non-stick heat conduction finish paint

[0027] Example 2 of the present invention consists of the following raw materials in parts by mass (wt%): 20 parts of D-100 water-based ceramic resin, 10 parts of PPS micropowder, 50 parts of SFN-2H polytetrafluoroethylene emulsion, and 1 part of nanometer aluminum oxide , 3 parts of NEROX505 transparent carbon black, 1 part of 100 mesh silver pearl powder, 8 parts of 5% graphene dispersion slurry, 0.5 parts of BYK-180 wetting and dispersing agent, 0.25 parts of BD-3062 defoamer, BD-2051 leveling 0.25 parts of agent, 0.5 parts of Pangel S9 hydrated magnesium silicate, and 0.5 parts of Degussa's A200 fumed silica.

Embodiment 3

[0028] Example 3 Electric baking pan inner pot non-stick heat conduction finish paint

[0029] Example 3 of the present invention consists of the following raw materials in parts by mass (wt%): 30 parts of D-810 water-based ceramic resin, 10 parts of PES micropowder, 40 parts of D60C PTFE emulsion, 2 parts of nano-alumina, NEROX505 transparent carbon black 3 parts, 1 part of 100 mesh silver flash paste, 8 parts of 5% graphene dispersion paste, 0.5 part of BYK-180 wetting and dispersing agent, 0.25 part of BD-3062 defoamer, 0.25 part of BD-2051 leveling agent, Pangel S9 0.5 parts of hydrated magnesium silicate, 0.5 parts of Degussa's A200 fumed silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com