Amorphous carbon material, preparation method thereof, negative electrode material and lithium ion battery

A technology of amorphous carbon and biomass materials, applied in the field of lithium ion batteries, amorphous carbon materials and preparation methods thereof, and negative electrode materials, can solve problems such as inability to meet, and achieve excellent structure, small specific surface area, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

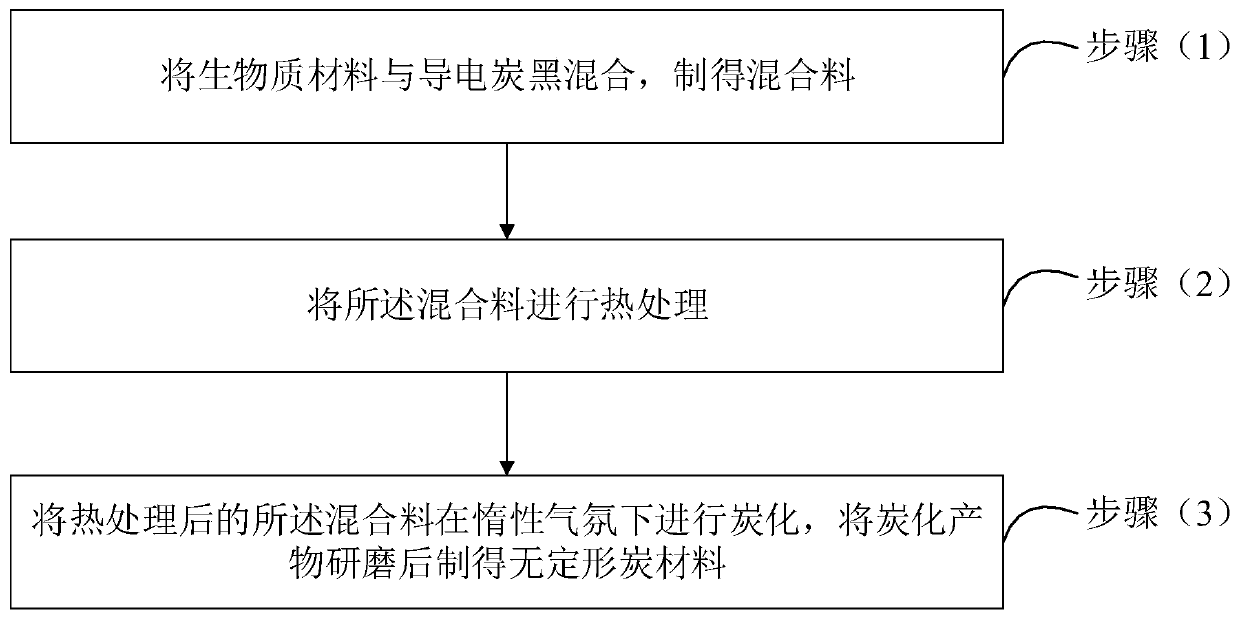

[0029] In order to solve the technical problems existing in the prior art, the embodiment of the present invention provides a preparation method of an amorphous carbon material, such as figure 1 As shown, the following steps may be included:

[0030] Step (1), mixing the biomass material with conductive carbon black to obtain a mixture;

[0031] Step (2), heat-treating the mixture;

[0032] Step (3), carbonizing the heat-treated mixture in an inert atmosphere, and grinding the carbonized product to obtain an amorphous carbon material; wherein, the carbonization temperature is higher than the heat treatment temperature.

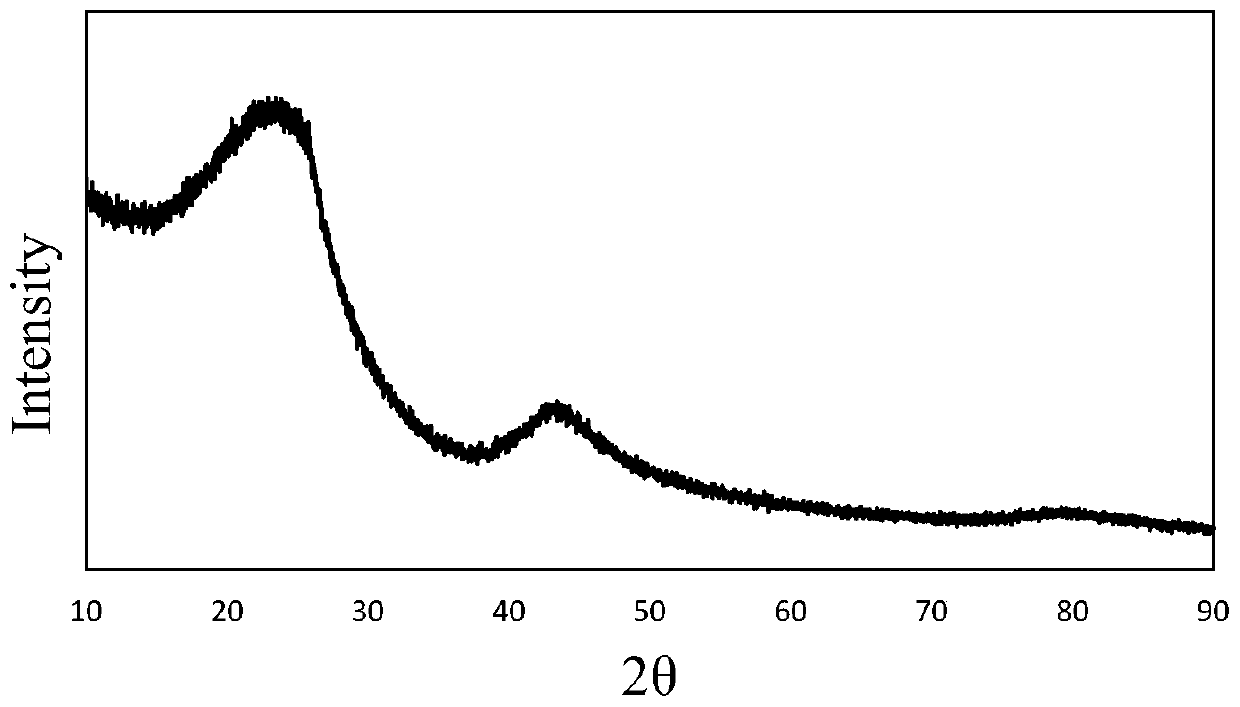

[0033] Such as figure 2 As shown, it is the X-ray diffraction pattern of the amorphous carbon material of the present invention. From figure 2 It can be seen from the steamed bread peaks formed in the figure that the carbon material prepared by the preparation method provided in the embodiment of the present invention is an amorphous carbon material.

...

Embodiment 1

[0051] This embodiment provides a method for preparing an amorphous carbon material, which is prepared according to the following steps:

[0052] Step (1), potato flour and conductive carbon black are mixed evenly according to the mass ratio of 100:1, obtain compound;

[0053] Step (2), heat up the mixture to 230°C at a heating rate of 8°C / min, and keep the temperature for 5 hours;

[0054] Step (3), transfer the mixture to a tube furnace with a nitrogen protective atmosphere, raise the temperature to 750°C at a heating rate of 2°C / min, and keep it warm for 1.5 hours; naturally cool the carbonized product to room temperature, and grind it to obtain Shaped carbon materials.

Embodiment 2

[0056] This embodiment provides a preparation method of an amorphous carbon material, which differs from the preparation method of Example 1 in that in step (1), the mass ratio of potato flour to conductive carbon black is 200:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com