Method for producing non-woven fabric through gas-stimulation reinforced fiber web

A technology of non-woven fabrics and reinforcing fibers, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of inability to carry out large-scale production, difficult to be practically applied, etc., to achieve the goal of not easy to breed bacteria, improve the production environment, and facilitate fiber bending. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

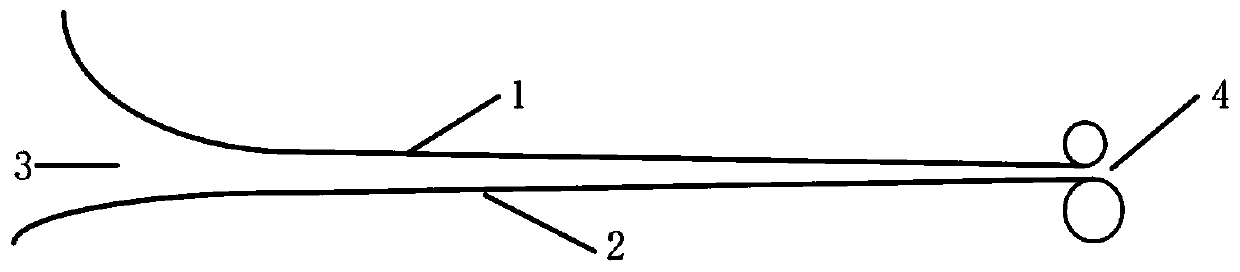

Image

Examples

Embodiment 1

[0036] Cotton is used as raw material to produce non-woven fabrics by dry carding into a web and air thorn reinforcement.

[0037] The cotton is domestic Xinjiang non-"three silk" cotton, the grade is 2 flowers, the length is 28mm, and the micronaire value is A grade.

[0038] Manufacturing equipment includes bale grabbers, openers, blenders, cleaners, cards, web lappers, web preformers, air lace machines and winders.

[0039] Cotton grabbing machine, also known as bale grabbing machine, is a machine for grabbing cotton fibers from cotton bales. The cotton grabbing machine adopts a reciprocating cotton grabbing machine, and generally uses blades (or saw blades) and ribs to grab cotton fiber raw materials from the surface of cotton bales. , transported by airflow or mechanically to the subsequent machine for further processing.

[0040] The cotton opener is installed downstream of the cotton bale condenser, and is used to open and remove impurities from the cotton fiber raw ma...

Embodiment 2

[0059] Cotton is used as raw material to produce non-woven fabrics through dry air-laid and air-punched reinforcement.

[0060] Manufacturing equipment includes plucking machine, cotton opener, cotton blending machine, air-laid machine, fiber web pre-forming machine, air thorn machine, winding machine.

[0061] The air-laid machine feeds the opened and mixed fibers into the high-speed rotating cylinder or thorns, and further combs them into single fibers. , condensed on the web curtain to form a fiber web. The air pressure of the compressed air is 0.2MPa, and the distance between the air-punching needle and the wet fiber web is 0.1mm.

[0062] Other equipment is identical with embodiment 1.

Embodiment 3

[0064] Using polypropylene masterbatch as raw material, the polymer is extruded and melt-blown into a web and reinforced with air thorns to produce non-woven fabrics.

[0065] Manufacturing equipment includes chip dryers, meltblown machines, air puncture machines, and winders.

[0066] The meltblown machine extrudes the polymer melt from the spinneret hole of the die to form a thin stream of melt, and the heated stretching air is blown out at high speed from the air channels on both sides to stretch the polymer stream, and the cooling air below The fibers are further cooled rapidly, and the formed superfine fibers are evenly spread on the web curtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com