Preparation method for high-combination interface stable type medical transfusion film material

A technology of stable interface and infusion film, which is applied in the field of medical materials, can solve the problems affecting the transparency of products, interface adhesive edge properties, processing temperature, large difference in flow properties, and poor flexibility of PET, etc., so as to reduce agglomeration, The effect of high surface energy and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

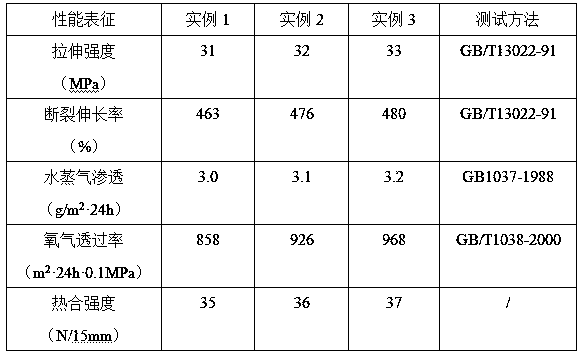

Examples

example 1

[0039] According to the mass ratio of 1:5, water glass with a Baume degree of 20 was added to deionized water, stirred and mixed, and the mass fraction of 1.5% phosphoric acid was added dropwise to adjust the pH to 1.5, stirred and sealed, and magnetically stirred at room temperature for 1h, static After standing for 25 minutes, adjust the pH to 7.0 with a mass fraction of 1% sodium hydroxide solution, let it stand and age for 6 hours, and collect the aged gel liquid; weigh 45 parts of absolute ethanol and 10 parts of trimethyl Chlorosilane and 6 parts of n-heptane were placed in a beaker, stirred and mixed, and the modified liquid was collected. Then, the aged gel liquid was placed in the modified liquid at a mass ratio of 1:5, left to stand for 20 hours, filtered and collected. Gel, washed 3 times with n-heptane, dried at normal pressure and 50°C for 3 hours to obtain modified silica airgel material, crushed and ground the modified silica airgel material through 500 sieves, ...

example 2

[0041]According to the mass ratio of 1:5, water glass with a Baume degree of 20 was added to deionized water, stirred and mixed, and the mass fraction of 1.5% phosphoric acid was added dropwise to adjust the pH to 1.5, stirred and sealed, and magnetically stirred at room temperature for 1.5h, After standing still for 27 minutes, adjust the pH to 7.0 with a mass fraction of 1% sodium hydroxide solution, let stand and age for 7 hours, and collect the aged gel liquid; weigh 47 parts of absolute ethanol and 13 parts of trimethyl Chlorosilane and 7 parts of n-heptane were placed in a beaker, stirred and mixed, and the modified liquid was collected. Then, the aged gel liquid was placed in the modified liquid at a mass ratio of 1:5, left to stand for 22 hours, filtered and collected. After washing 4 times with n-heptane, dry at normal pressure and 53°C for 4 hours to obtain modified silica airgel material, crush and grind the modified silica airgel material through 500 sieves , to ob...

example 3

[0043] According to the mass ratio of 1:5, water glass with a Baume degree of 20 was added to deionized water, stirred and mixed, and the mass fraction of 1.5% phosphoric acid was added dropwise to adjust the pH to 1.5, stirred and sealed, magnetically stirred at room temperature for 2 hours, static After standing for 30 minutes, adjust the pH to 7.0 with a mass fraction of 1% sodium hydroxide solution, let it stand and age for 8 hours, and collect the aged gel liquid; weigh 50 parts of absolute ethanol and 15 parts of trimethyl Chlorosilane and 8 parts of n-heptane were placed in a beaker, stirred and mixed, and the modified liquid was collected. Then, the aged gel liquid was placed in the modified liquid at a mass ratio of 1:5, and stood for 24 hours, filtered and collected. gel, washed 5 times with n-heptane, and dried at normal pressure at 55°C for 5 hours to obtain a modified silica airgel material, which was crushed and ground through a 500 sieve, Obtain airgel modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com