A processing pretreatment method for electrolytic grinding of high chromium alloys based on naoh electrolyte

A high-chromium alloy, electrolytic grinding technology, applied in the field of electrochemical assisted machining, can solve the problems of difficulty and difficult to control the thickness of the corrosion layer to achieve precision machining, poor corrosion conditions, low machining efficiency, etc. The effect of reducing tool wear and improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with example the present invention will be further described.

[0019] The specific steps of using the method of the present invention to process 20mm * 20mm high chromium alloy plate are as follows:

[0020] Step 1: Potentiostatic Polarization Pretreatment of High Chromium Alloy

[0021] A three-electrode electrochemical system is used for electrochemical treatment, in which the working electrode is a high-chromium alloy with a smooth surface, the reference electrode is an Ag / AgCl electrode, and the auxiliary electrode is a platinum grid electrode; the electrolyte is a NaOH solution with a concentration of 1M.

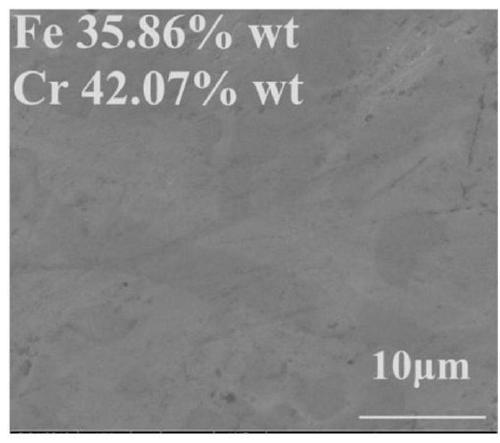

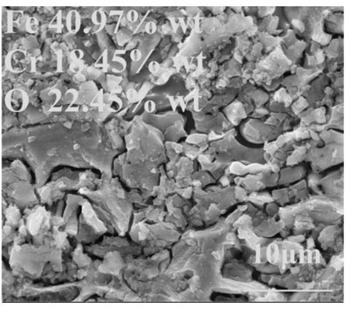

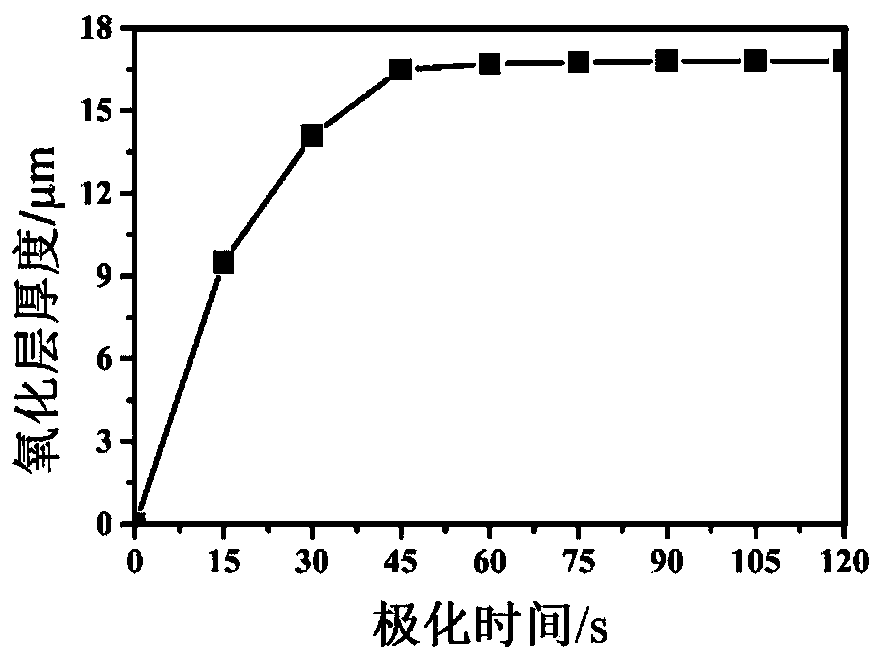

[0022] The electrochemical treatment is a constant potential polarization method, and the treatment is performed at a constant potential of 5V for 15s. After the electrochemical treatment, the samples were taken out, rinsed with deionized water, and dried. The scanning electron microscope photo of the obtained sample surface is shown in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com