Non-stick pan

A technology of non-stick pans and pan bodies, which is applied to the special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc. It can solve the problems of short non-stick life, easy aging, and decline in non-stick properties, and achieve good high temperature resistance and Salt spray corrosion resistance, improved scratch resistance, good hydrophobic and oleophobic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

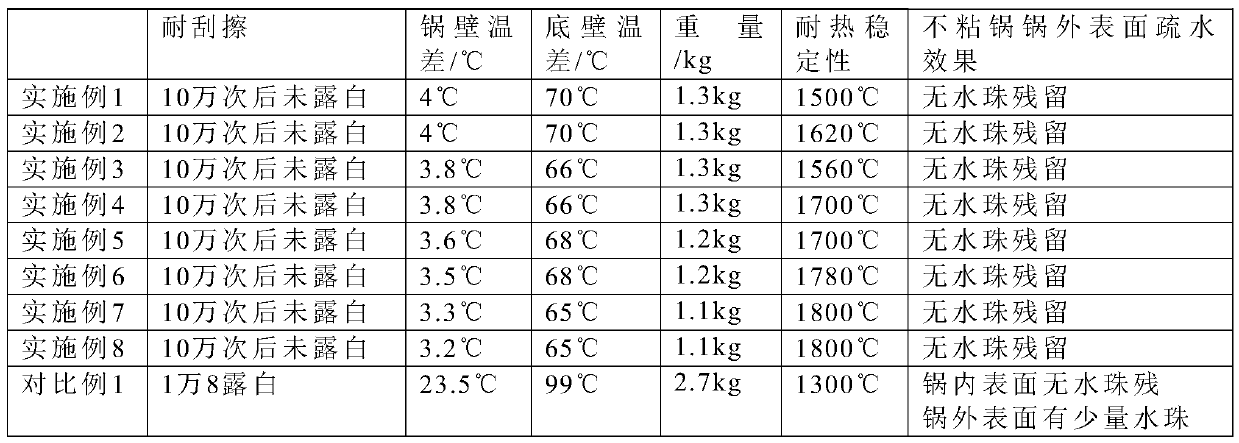

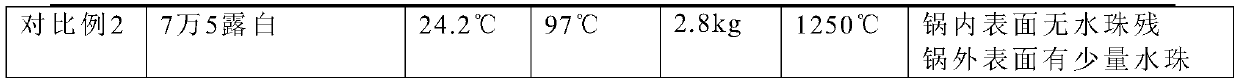

Examples

Embodiment 1

[0013] A non-stick pan, the pan body and the pan handle are integrally cast from a molten alloy, wherein the composition of the molten alloy is as follows: 3% cobalt, 2% titanium, 0.01% germanium, 0.05% selenium, 0.5% aluminum oxide, and the balance For iron and unavoidable impurities.

Embodiment 2

[0015] A non-stick pan, the pan body and the pan handle are integrally cast from a molten alloy, wherein the composition of the molten alloy is as follows: 10% cobalt, 0.05% titanium, 0.5% germanium, 0.01% selenium, 10% aluminum oxide, and the balance For iron and unavoidable impurities.

Embodiment 3

[0017] A non-stick pan, the pan body and the pan handle are integrally cast from a molten alloy, wherein the composition of the molten alloy is as follows: 4% cobalt, 1.8% titanium, 0.05% germanium, 0.04% selenium, 1% aluminum oxide, and the balance For iron and unavoidable impurities. A polysilazane modified material is attached to the outer surface of the non-stick pan, and the raw materials of the polysilazane modified material include 100 parts by weight of polysilazane, 1 part of silane coupling agent, 3 parts of silicon dioxide parts, 0.01 parts of perfluoropolyether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com