Method for induction sintering method for preparing coating with electron beam cladding and application

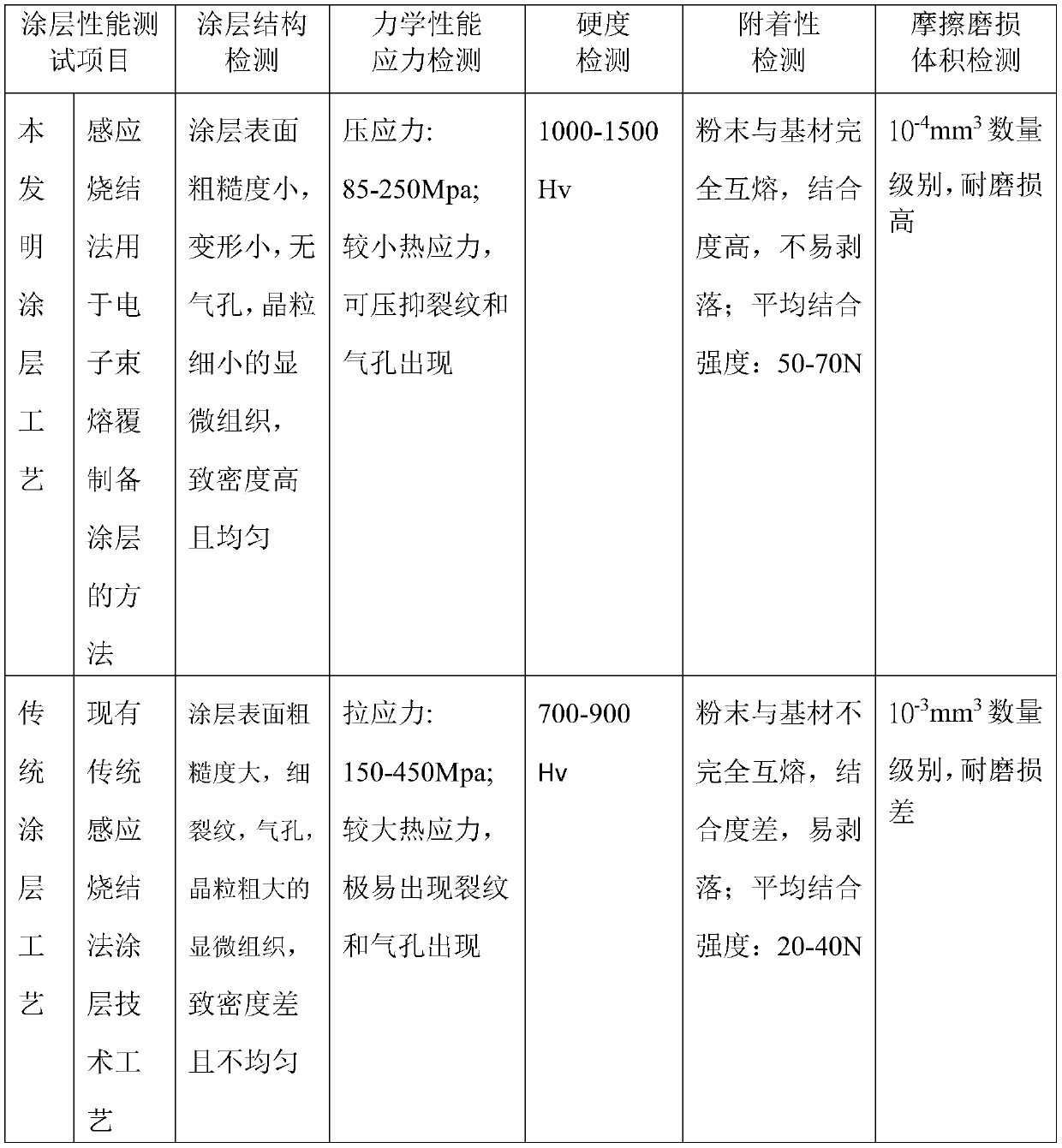

A technology of electron beam cladding and induction sintering, which is applied in the direction of coating, metal material coating process, metal processing equipment, etc. It can solve the problems of affecting performance, low bonding force between coating and substrate, and large internal stress of diamond. , to achieve high power density, avoid easy gasification and splashing, and avoid easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

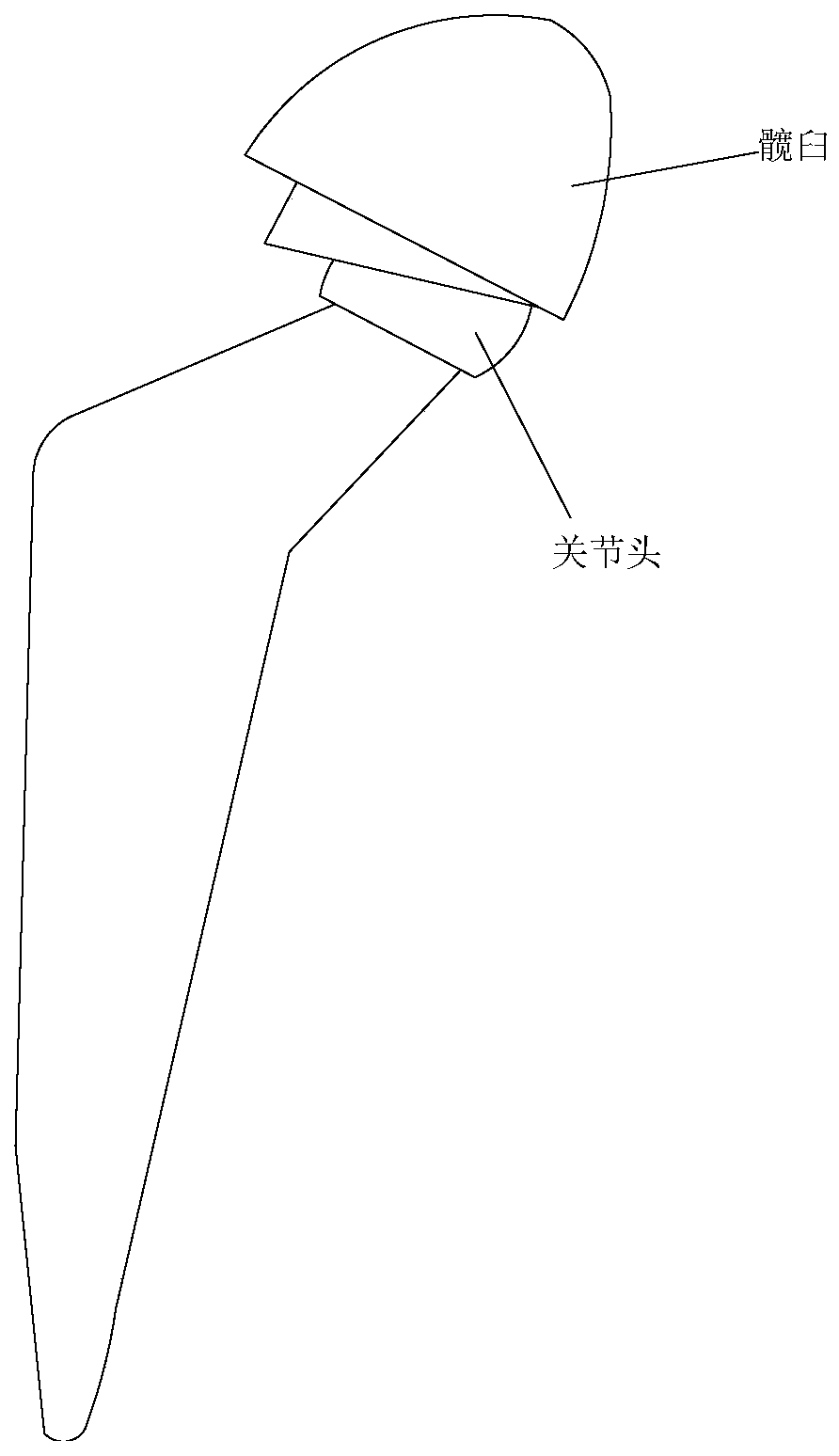

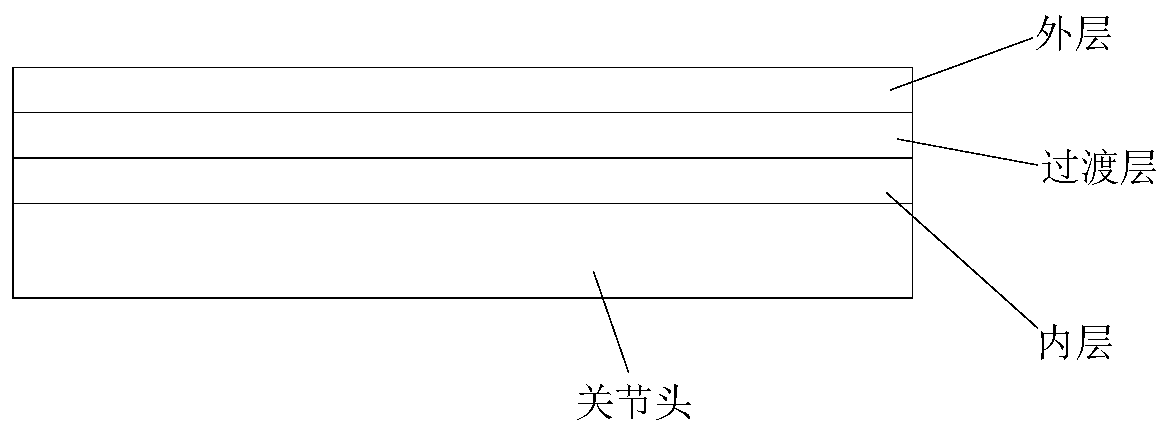

[0044] Embodiment 1: A kind of induction sintering method of the present invention is used in the method for electron beam cladding preparation coating, specifically comprises the following steps:

[0045] 1) Pretreat the base material to remove dust, grease and rust on the surface of the base material; the base material is usually metal or ceramic material;

[0046] 2) To process the powder to be clad, place the powder to be clad in a planetary ball mill, then put it into a drying oven to dry for 2 hours, then mix the powder to be clad evenly into the binder to achieve uniform mixing and blending of the original powder Paste or pasty powder, ready for use; the binder is paraffin-polymer system coating, and the paraffin-polymer coating is composed of the following components in mass fraction: paraffin wax 52%, polypropylene 28%, polyethylene 16% , stearic acid 4%;

[0047] 3) Squeeze the paste or pasty powder on the surface of the base material by metal injection molding meth...

Embodiment 2

[0053] Embodiment 2: A kind of induction sintering method of the present invention is used in the method for electron beam cladding preparation coating, specifically comprises the following steps:

[0054] 1) Pretreat the base material to remove dust, grease and rust on the surface of the base material; the base material is usually metal or ceramic material;

[0055] 2) To process the powder to be clad, place the powder to be clad in a planetary ball mill, then put it into a drying oven to dry for 2 hours, then mix the powder to be clad evenly into the binder to achieve uniform mixing and blending of the original powder Paste or pasty powder, ready for use; the binder is paraffin-polymer system coating, and the paraffin-polymer coating is composed of the following components in mass fraction: paraffin wax 52%, polypropylene 28%, polyethylene 16% , stearic acid 4%;

[0056] 3) Squeeze the paste or pasty powder on the surface of the base material by metal injection molding meth...

Embodiment 3

[0062] Embodiment 3: A method for preparing a coating by electron beam cladding by induction sintering of the present invention, specifically comprising the following steps:

[0063] 1) Pretreat the base material to remove dust, grease and rust on the surface of the base material; the base material is usually metal or ceramic material;

[0064] 2) To process the powder to be clad, place the powder to be clad in a planetary ball mill, then put it into a drying oven to dry for 2 hours, then mix the powder to be clad evenly into the binder to achieve uniform mixing and blending of the original powder Paste or pasty powder, ready for use; the binder is paraffin-polymer system coating, and the paraffin-polymer coating is composed of the following components in mass fraction: paraffin wax 52%, polypropylene 28%, polyethylene 16% , stearic acid 4%;

[0065] 3) Squeeze the paste or pasty powder on the surface of the base material by metal injection molding method, press it with a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com