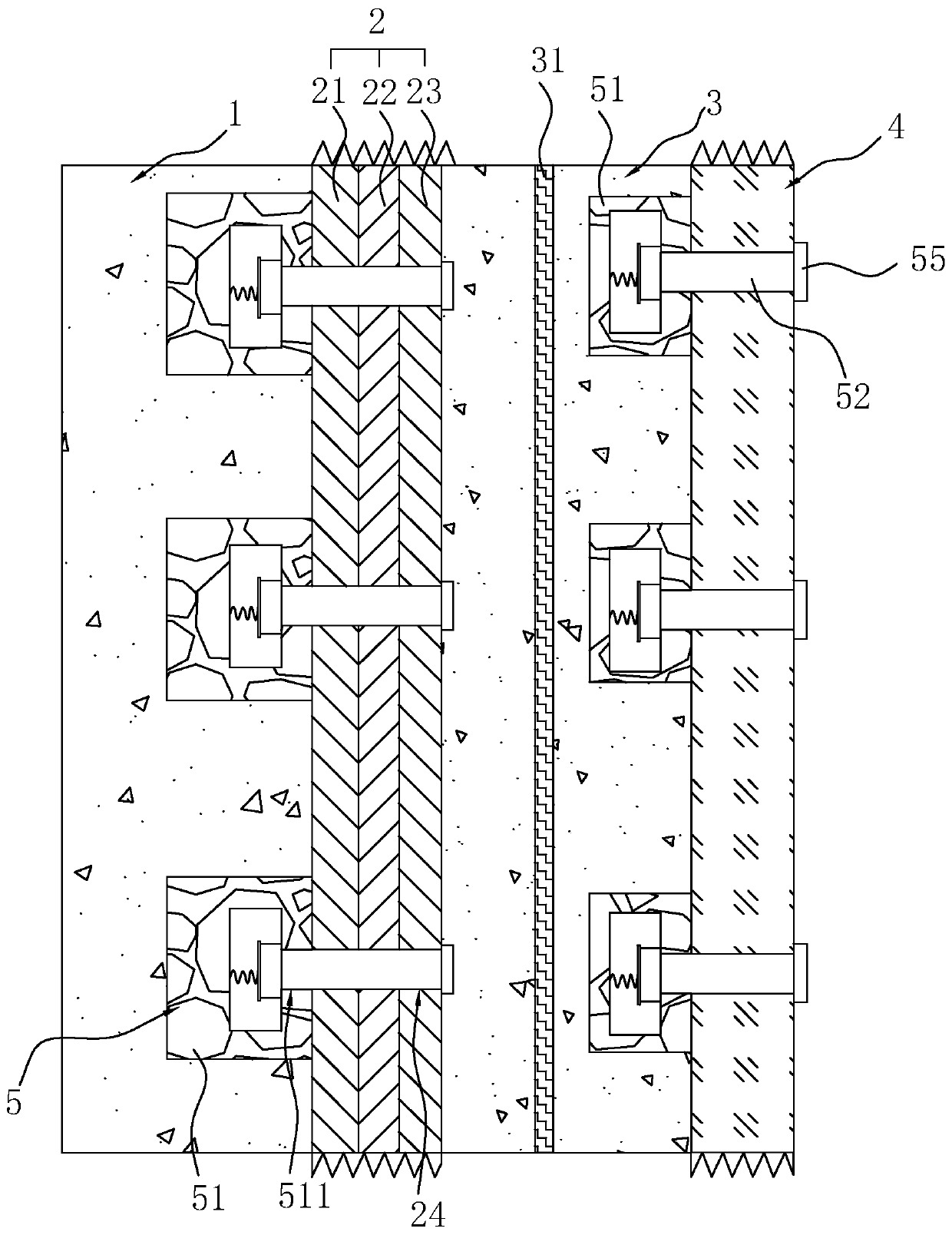

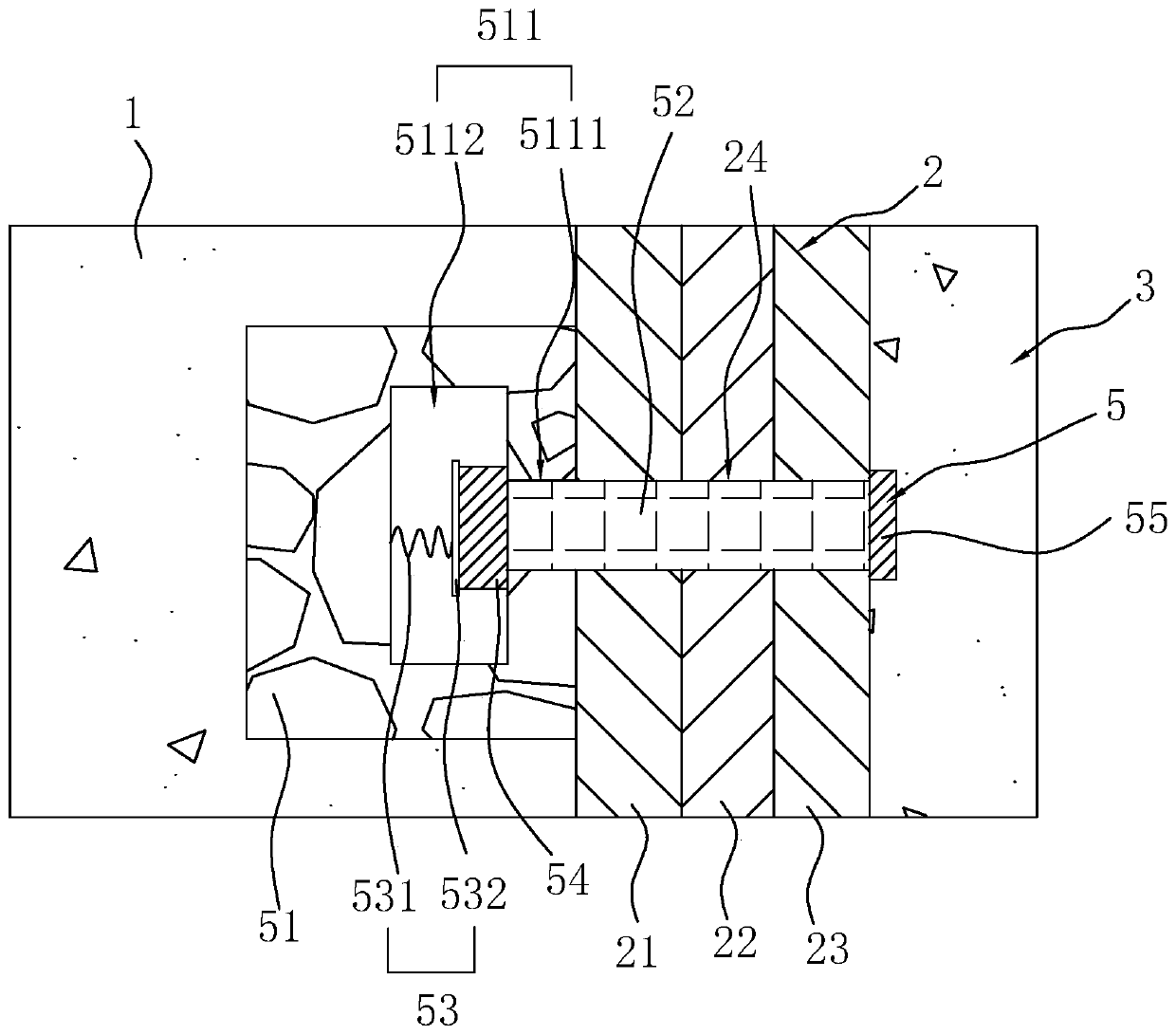

External wall decoration structure and construction method thereof

A technology of exterior wall decoration and construction method, applied in building structure, building, floor and other directions, can solve problems such as cracking of board seams and lifting of thermal insulation boards, so as to enhance thermal insulation performance and anti-cracking performance, improve stability, The effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] A preparation method of anti-crack mortar, comprising the following steps:

[0048] Mix 85kg of Portland cement, 100kg of sand, 15kg of diatomaceous earth, 12kg of sodium bentonite, and 5kg of hydroxypropyl methylcellulose and stir for 25 minutes, then add 15kg of urea, 8kg of silane coupling agent and 4kg of talc, and stir for 25 minutes. Then add 15kg of water and 25kg of vitrified microspheres, stir for 15 minutes, add 8kg of polypropylene fiber and 7kg of air-entraining agent, and stir for 35 minutes to obtain the product.

[0049] Wherein, the air-entraining agent is sodium rosinate.

preparation example 2

[0051] A preparation method of anti-crack mortar, comprising the following steps:

[0052] Mix 70kg of Portland cement, 80kg of sand, 10kg of diatomaceous earth, 10kg of sodium bentonite, and 3kg of hydroxypropyl methylcellulose and stir for 25 minutes, then add 10kg of urea, 6kg of silane coupling agent and 2kg of talc, and stir for 25 minutes. Then add 10kg of water and 20kg of vitrified microspheres, stir for 15 minutes, add 5kg of polypropylene fiber and 4kg of air-entraining agent, stir for 35 minutes, and you get it.

[0053] Wherein, the air-entraining agent is sodium rosinate.

preparation example 3

[0055] A preparation method of anti-crack mortar, comprising the following steps:

[0056] Mix 100kg of Portland cement, 120kg of sand, 20kg of diatomaceous earth, 15kg of sodium bentonite, and 6kg of hydroxypropyl methylcellulose for 25 minutes, then add 20kg of urea, 10kg of silane coupling agent and 6kg of talc, and stir for 25 minutes. Then add 20kg of water and 30kg of vitrified microspheres, stir for 15 minutes, add 10kg of polypropylene fiber and 10kg of air-entraining agent, stir for 35 minutes, and you get it.

[0057] Wherein, the air-entraining agent is sodium rosinate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com