Arsenic-containing gypsum recycling treatment method and application of the treated and recycled low-arsenic gypsum

A technology of recycling and gypsum, applied in the field of waste recycling, can solve the problems of high arsenic gypsum being unable to be used twice, arsenic pollution, etc., and achieve the effects of improving secondary utilization rate, high safety, and improving resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The source of arsenic-containing gypsum: the arsenic-calcium slag obtained by one-step neutralization of arsenic-containing polluted acid by a heavy non-ferrous smelting enterprise in Yunnan was used as raw material to remove arsenic and fix arsenic by acid leaching and scorodite precipitation method; The composition content of arsenic gypsum is: Ca21wt.%, As1.81wt.%, Cu1549mg / kg, Zn672mg / kg, Pb977mg / kg and Cd391mg / kg. Add 500g of arsenic-calcium slag into 500mL of clear water and make a mixed slurry of arsenic-calcium slag under sufficient stirring conditions. Use a peristaltic pump to add the mixed slurry of arsenic-calcium slag into the sulfuric acid solution and adjust the pH value with 6mL / L sulfuric acid To 2.0, solid-liquid separation to obtain arsenic-containing gypsum and arsenic-containing solution, the arsenic-containing solution can be removed and fixed by scorodite precipitation process well known in the industry.

[0043] Recycling treatment of arsenic-con...

Embodiment 2

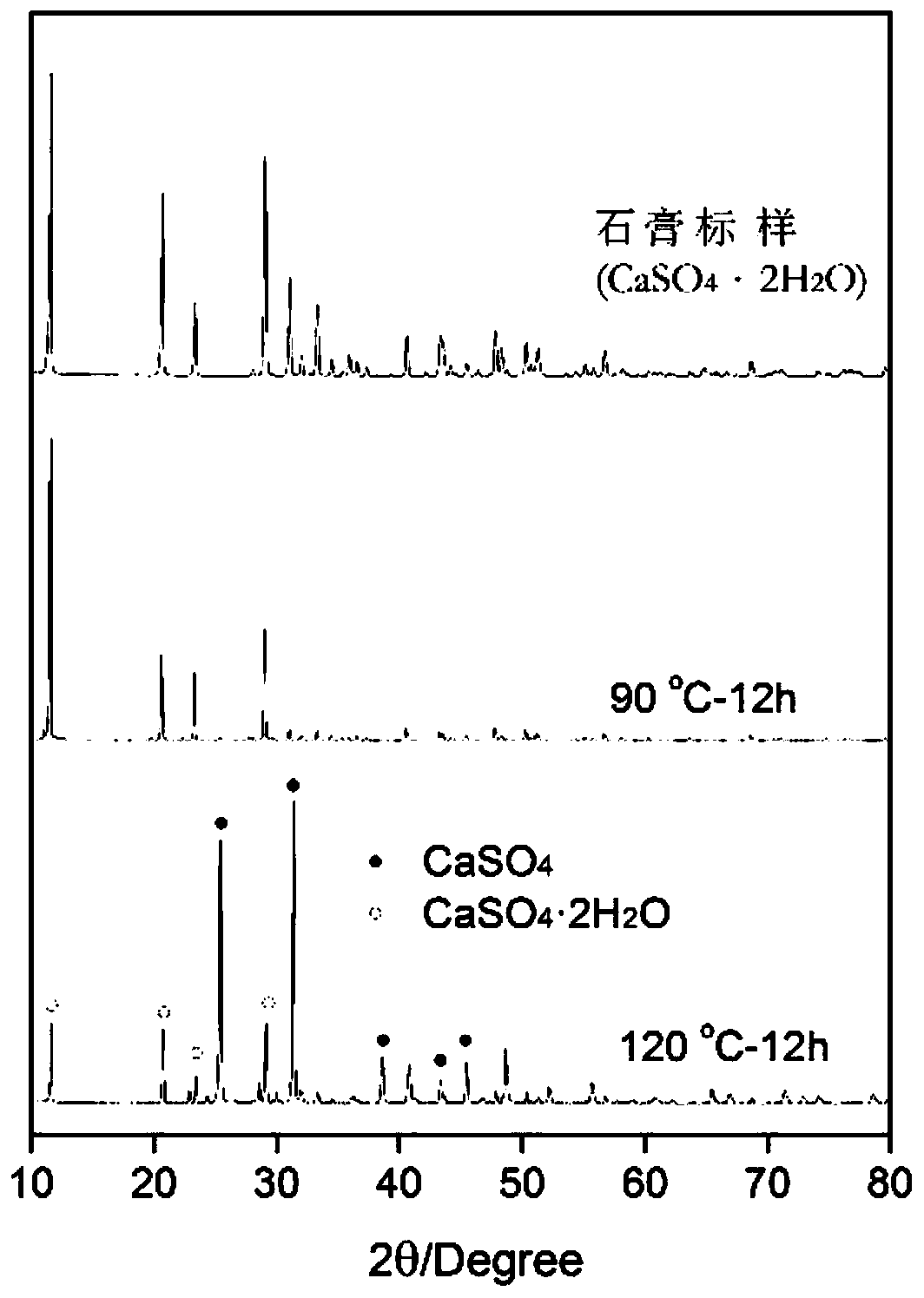

[0051] The recrystallization temperature was controlled to be 120° C., and other processes and parameters were the same as in Example 1.

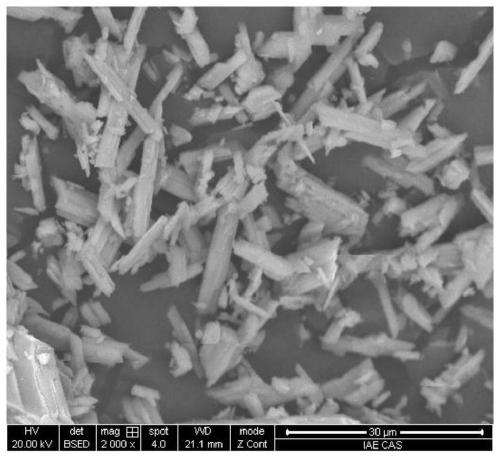

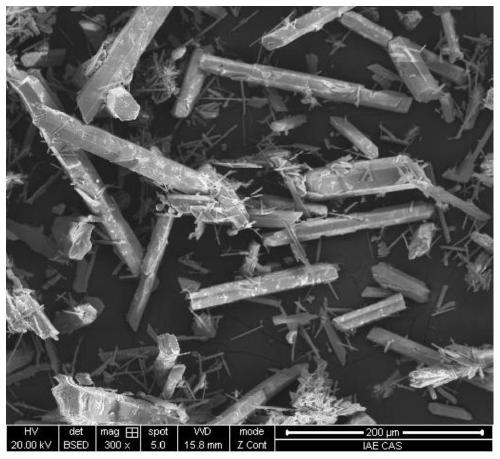

[0052] Low-arsenic gypsum was observed using a scanning electron microscope, and the observation results can be found in Figure 5 . Depend on figure 1 with Figure 5 It can be seen from the comparison that the arsenic-containing gypsum originally had a short and thick rod-like structure, but after recrystallization treatment at 120 °C, its morphology changed significantly and became a regular cuboid shape.

[0053] Extend the recrystallization time to 24h, and adopt the same test method as in Example 1, under different recrystallization time conditions, carry out the leaching toxicity test on the obtained low-arsenic gypsum. The test results are shown in Table 2; The arsenic leaching figure of low-arsenic gypsum under the condition of crystallization time, see Image 6 .

[0054] Table 2 Example 2 The amount of arsenic leached from lo...

Embodiment 3

[0058] Source of arsenic-containing gypsum: lime arsenic-containing wastewater (H 2 SO 4 : 100g / L; As(V): 6g / L) adjusted to pH 12.0, solid-liquid separation to obtain arsenic-calcium slag and low-arsenic waste liquid, adding arsenic-calcium slag to sulfuric acid to obtain arsenic-containing gypsum and arsenic-containing solution ( The addition method is as in Example 1), and the arsenic-containing solution can be removed and fixed by the well-known scorodite precipitation process in the industry.

[0059] Recycling treatment of arsenic-containing gypsum: Add 100g of arsenic-containing gypsum into 400mL of hydrochloric acid solution with a concentration of 6moL / L, stir well, and mix evenly to obtain a slurry; then raise the temperature of the slurry to 120°C and keep it warm for 4 hours for dissolution and recrystallization to obtain Solid-liquid mixture; finally, the solid-liquid mixture is taken out and cooled to room temperature, and the solid-liquid is separated to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com