Compounded antifoamer, preparation method therefor and application of compounded antifoamer

A defoamer and thickener technology, which is applied in the field of compound defoamer and its preparation, can solve the problems of low desulfurization efficiency of desulfurizer, unfavorable regeneration of desulfurizer, and poor ability to suppress foam, so as to reduce solution loss and reduce High, absorption-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

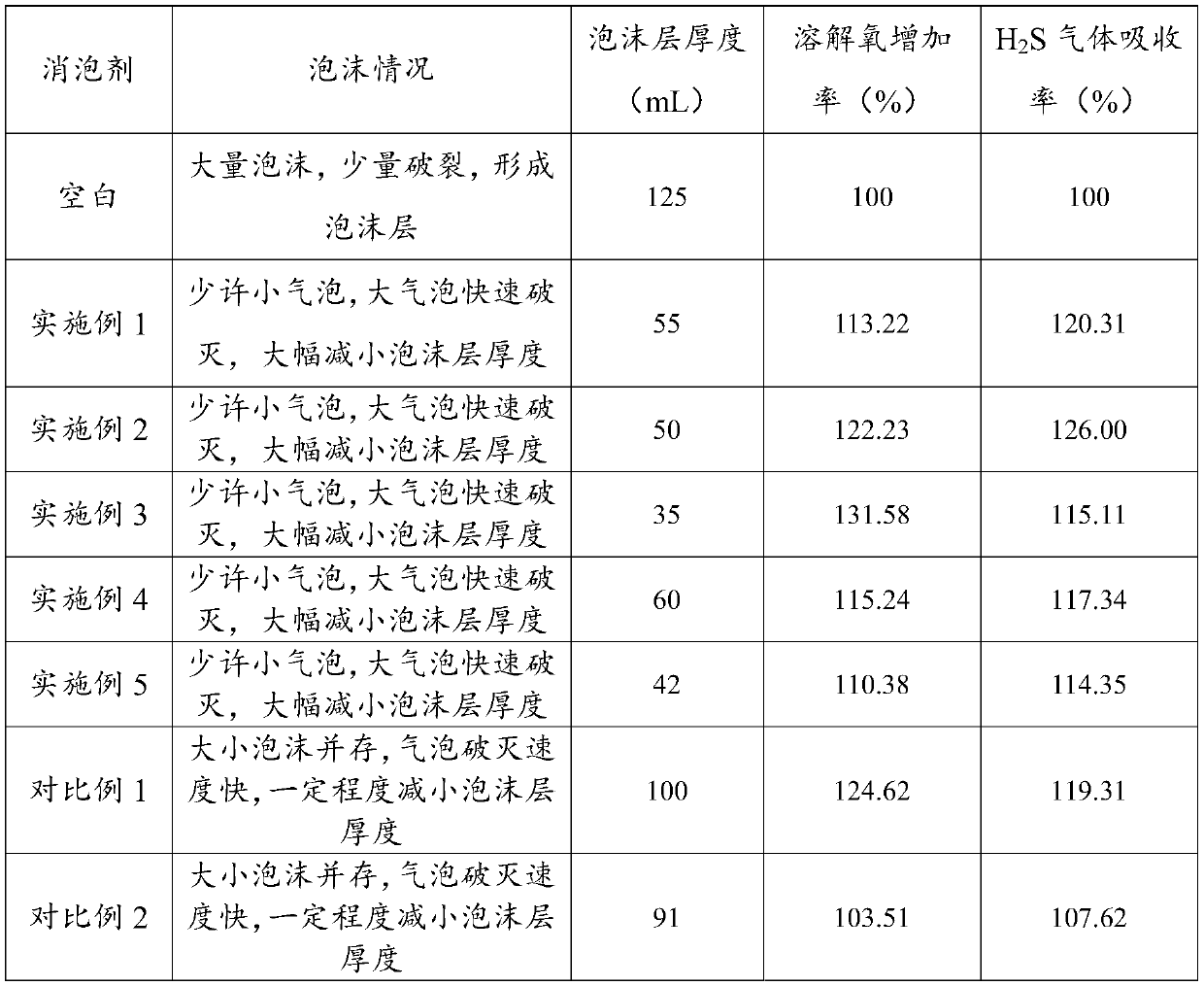

Examples

Embodiment 1

[0026] This embodiment provides a compound defoamer, and its preparation method includes the following steps:

[0027] Mix 10g sodium carboxymethylcellulose and 330g deionized water uniformly to obtain an aqueous thickener solution; at 45°C, mix 5g perfluorosilicone oil, 5g polyether, 40g dimethyl silicone oil, 20g nano silicon dioxide, and 20g Mix pan 60, 20g Tween 60 and 550g deionized water, stir for 1h to make the dispersion uniform, then slowly add the above thickener aqueous solution to it, stir at 70℃ at high speed until a uniform mixture is obtained, keep stirring for 2h, stop Stir and cool to room temperature to obtain the compound defoamer.

Embodiment 2

[0029] This embodiment provides a compound defoamer, and its preparation method includes the following steps:

[0030] Mix 10g of guar gum and 290g of deionized water uniformly to obtain a thickener aqueous solution; at 45°C, 10g of high phenyl silicone oil, 10g of polyether modified siloxane, 10g of fluoroether modified siloxane, 70g portion Low-hydrogen silicone oil, 20g nano-silica, 20g Span 80, 20g Tween 80 and 540g deionized water are mixed, stirred for 1h to make the dispersion uniform, and then slowly add the above thickener aqueous solution to it, at a high speed at 70℃ Stir until a uniform mixture is obtained, continue to keep stirring for 2 hours, stop stirring, and cool to room temperature to obtain the compound defoamer.

Embodiment 3

[0032] This embodiment provides a compound defoamer, and its preparation method includes the following steps:

[0033] Mix 10g sesame gum and 290g deionized water uniformly to obtain a thickener aqueous solution; at 45°C, 20g fluoroether modified siloxane, 10g polyether, 60g dimethyl silicone oil, 20g nano silica, 20g Laureth polyoxyethylene ether, 20g alkylphenol polyoxyethylene ether and 550g deionized water are mixed, stirred for 1 hour to make it uniformly dispersed, then slowly add the above-mentioned thickener aqueous solution to it, and stir at high speed at 70°C until uniform mixing is obtained Liquid, continue to keep stirring for 2 hours, stop stirring, and cool to room temperature to obtain the compound defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com