A method for separating uranium and molybdenum by fluorination using nitrogen trifluoride as fluorinating agent

A technology for chemical separation of uranium and nitrogen trifluoride, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., and can solve the problems of complex recovery of high-purity molybdenum elements, low separation efficiency of uranium and molybdenum, and complicated operations. , to achieve the effect of reducing the generation of radioactive waste, stable properties and low chemical toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1UF 4 Separation of uranium and molybdenum in a mixture with molybdenum

[0059] (1) 5.0g UF 4 A mixture of molybdenum and molybdenum (wherein UF 4 Mass 4.0g, Mo powder 1.0g) placed in the reactor, cover the reactor lid, replace the atmosphere in the reactor with high-purity argon.

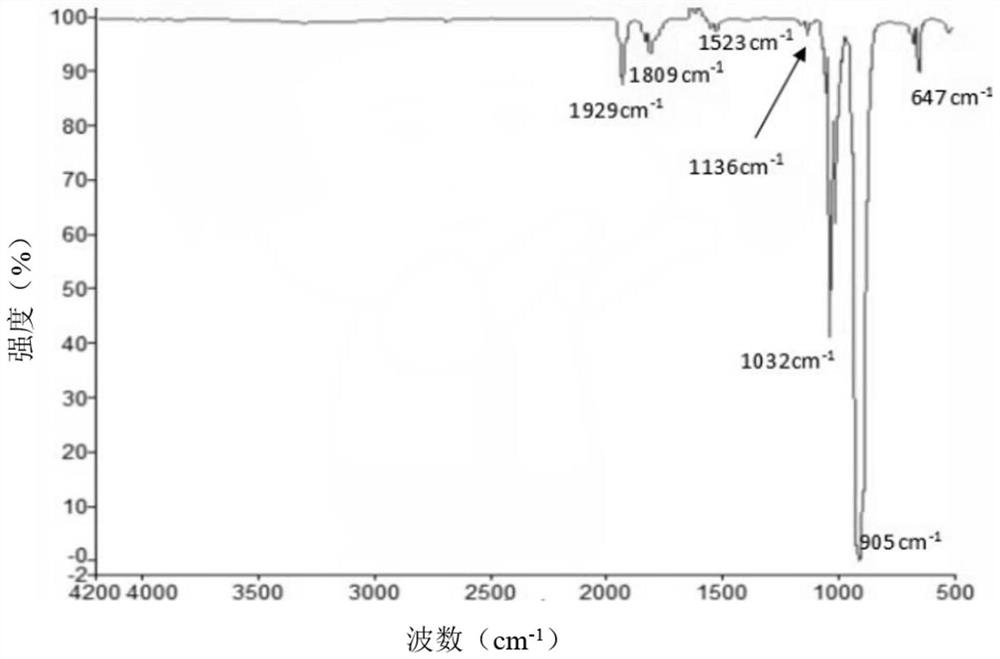

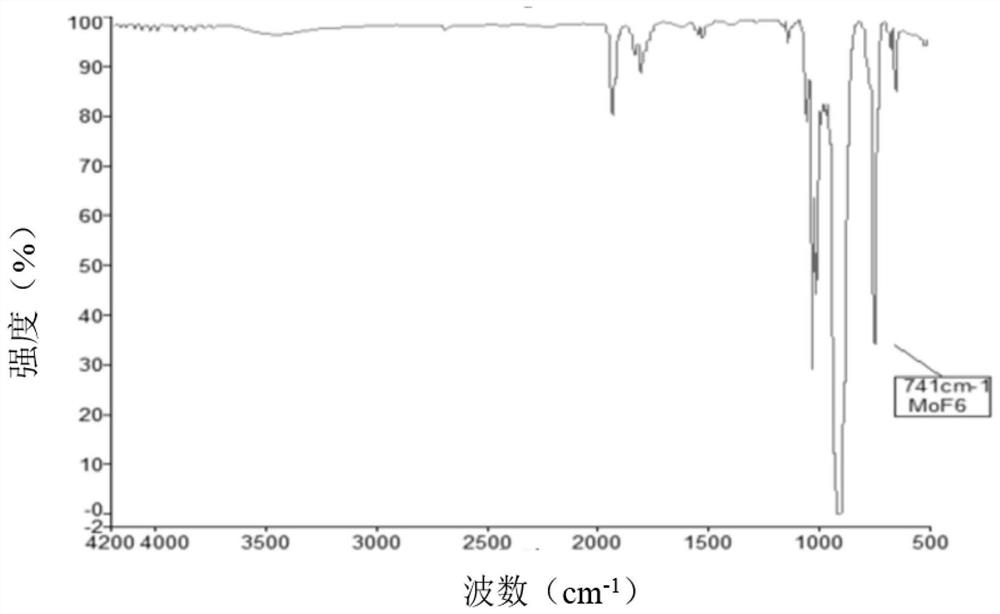

[0060] (2) Heating the reactor to raise the temperature from room temperature to 350°C, keep it warm for 2 hours, and pass a mixed gas of nitrogen trifluoride and argon (NF 3 The volume fraction is 20%), flow is 0.3L / min, adopts Fourier transform infrared spectrometer to monitor reactor outlet gas, the result is as follows figure 2 shown; two-stage MgF 2 Adsorption column recovery of MoF 6 product, the temperature of the adsorption column is 125°C; after 70min, the MoF in the outlet gas of the reactor 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0061] (3) After continuing to heat th...

Embodiment 2

[0063] Embodiment 2UO 2 Separation of uranium and molybdenum in a mixture with molybdenum

[0064] (1) Add 3.0g UO 2 A mixture of molybdenum and molybdenum (wherein UO 2 Mass 2.8g, Mo powder 0.2g) placed in the reactor, cover the reactor lid, replace the atmosphere in the reactor with high-purity argon.

[0065] (2) Heating the reactor to raise the temperature from room temperature to 400°C, keep it warm for 1h, and pass a mixed gas of nitrogen trifluoride and argon (NF 3 The volume fraction is 30%), the flow rate is 0.2L / min, the reactor outlet gas is monitored by Fourier transform infrared spectrometer; the MoF is recovered by two-stage cold trap 6 products, the condensing temperature is -40°C; after 20 minutes, the MoF in the outlet gas of the reactor 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0066] (3) After continuing to heat the reactor to raise the temperature to 550°C, ...

Embodiment 3

[0068] Example 3LiF-BeF 2 Separation of Uranium and Molybdenum in Molten Salt System

[0069] (1) 50g LiF-BeF 2 Molten salt (of which UF 4 Mass 5.0g, Mo mass 0.5g) placed in the reactor, cover the reactor lid, replace the atmosphere in the reactor with high-purity argon.

[0070] (2) Heating the reactor to raise the temperature from room temperature to 450°C, keep it warm for 3 hours, and feed nitrogen trifluoride and argon mixed gas (NF 3 The volume fraction is 10%), the flow rate is 0.5L / min, and the gas at the outlet of the reactor is monitored by a Fourier transform infrared spectrometer; two-stage MgF 2 Adsorption column recovery of MoF 6 product, the temperature of the adsorption column is 110°C; after 40min, the MoF in the outlet gas of the reactor 6 When the concentration is lower than the lower limit of infrared detection, stop passing nitrogen trifluoride mixed gas at this time.

[0071] (3) After continuing to heat the reactor to raise the temperature to 700°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com