Antifatigue torsion beam formed through pipe punching

A stamping forming and anti-fatigue technology, applied in the field of automobile parts, can solve the problems such as the need to improve the anti-fatigue ability of the beam, the deformation of the side wall of the pipe, and the easy fracture of the beam, so as to improve the operation stability, prevent cracking, and improve the anti-fatigue ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

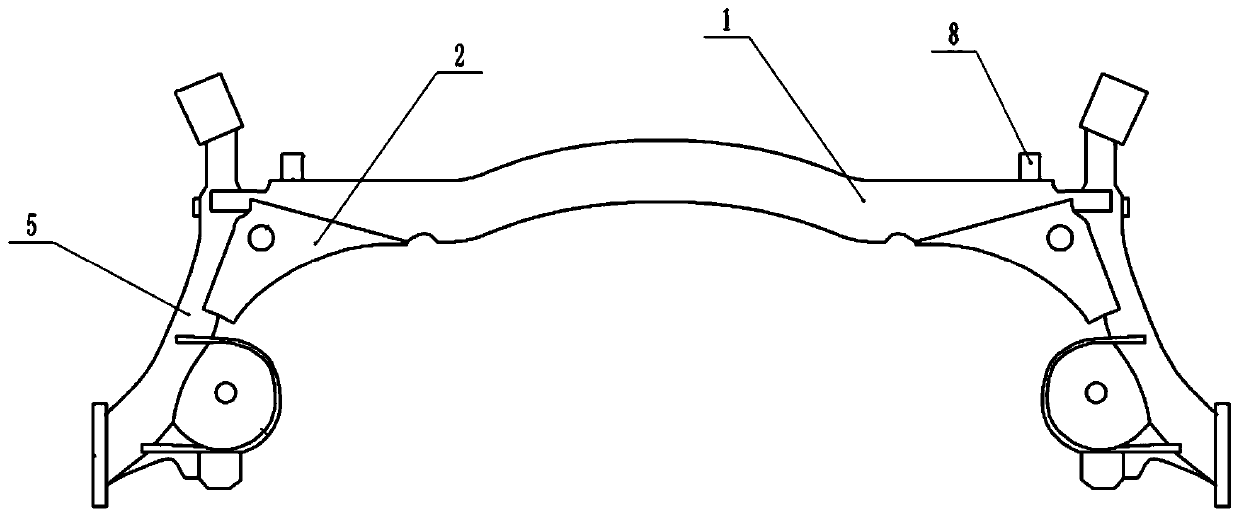

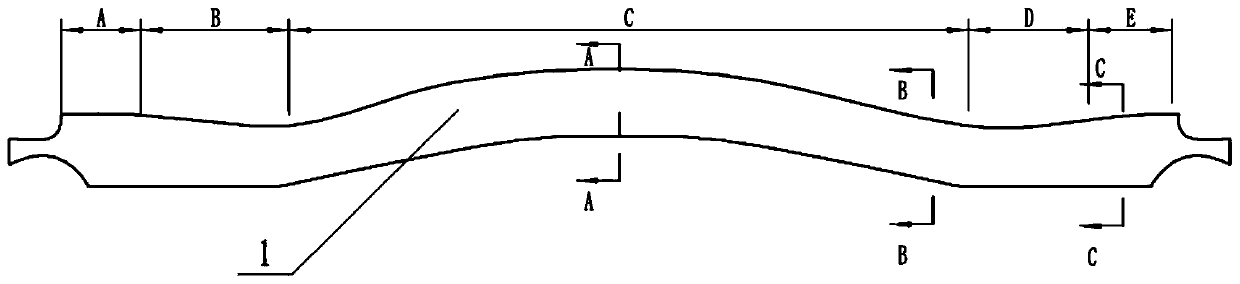

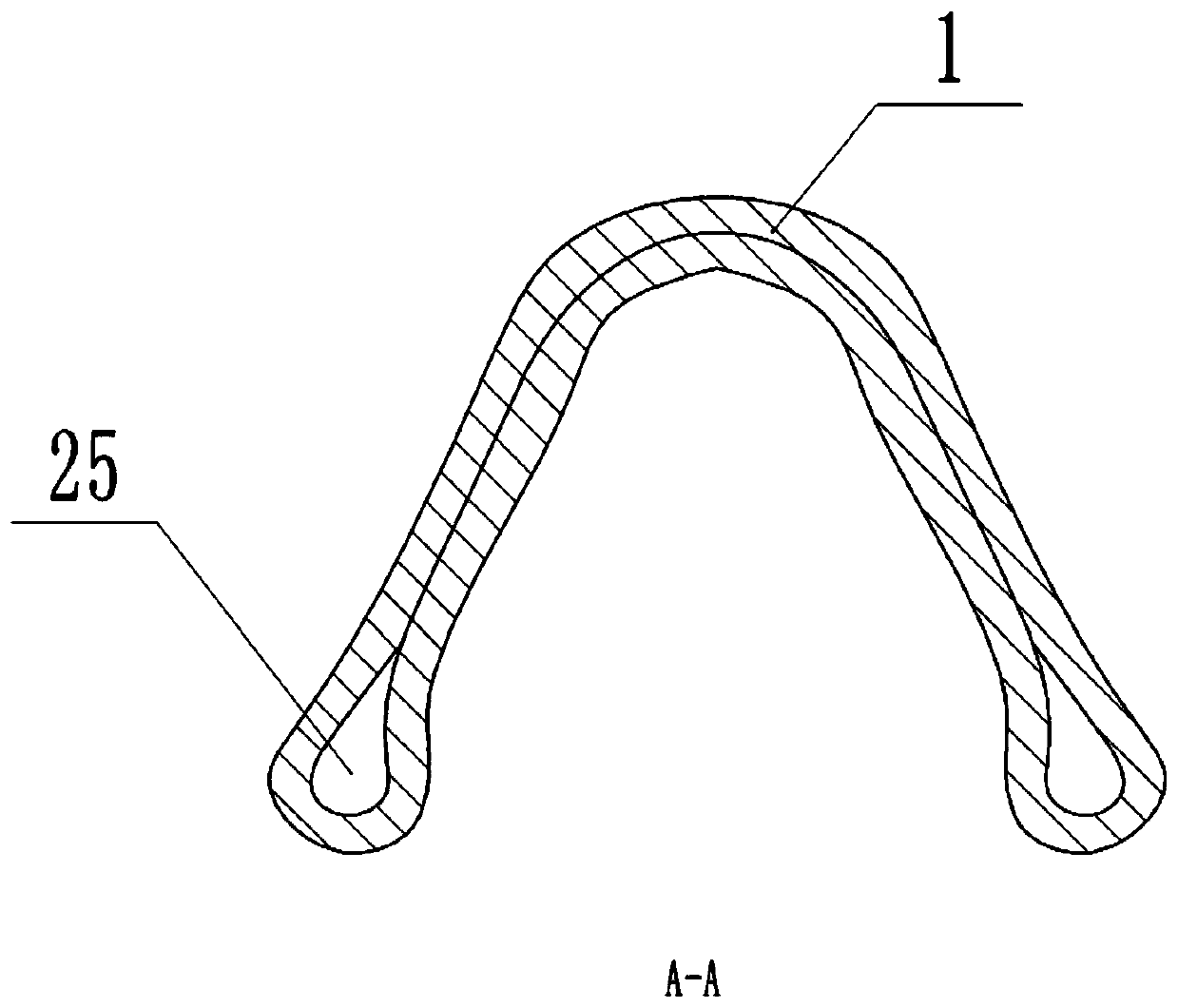

[0033] Basic as attached figure 1 As shown: the anti-fatigue torsion beam formed by control stamping, including the beam 1 and the longitudinal arm 5, the longitudinal arm 5 is welded to the two ends of the beam 1, specifically, the two ends of the beam 1 are provided with interfaces, combined with figure 2 As shown, the edges of the joints at both ends of the crossbeam 1 are recessed toward the middle of the crossbeam 1, so that the joints at both ends of the crossbeam 1 can wrap the outer wall of the longitudinal arm 5 because the shape of the joint is arc-shaped, so that the longitudinal arm 5 is welded on the crossbeam 1 It is relatively smooth and smooth, and the welding strength of the longitudinal arm 5 and the beam 1 can also be improved.

[0034] One end of the trailing arm 5 is provided with a sleeve, and the other end of the trailing arm 5 is provided with a hub seat. The end of the longitudinal arm 5 close to the hub seat is provided with a spring seat, which is ...

Embodiment 2

[0048] combine Figure 8 As shown, the beam 1 is fixed with an illumination mechanism 9 . Specifically, combine Figure 9 As shown, the lighting mechanism 9 includes a base plate 10 welded on the beam 1, a lighting lamp 14 located on the base plate 10, and a protective cover 11 for covering the lighting lamp 14, and the protective cover 11 can be snapped through a clamp block and a slot Covered on the bottom plate 10 in a way. combine Figure 10 As shown, the central position of the bottom of the base plate 10 is provided with a hinged hole 19, and the surrounding of the hinged hole 19 is provided with annularly distributed support holes 18. The number of rings of the support holes 18 in this embodiment is two rings, and the support holes of the inner ring The number of 18 is six, the number of supporting holes 18 of the outer ring is ten, and the insides of the supporting holes 18 are all bonded with magnets. combine Figure 9 As shown, the protective cover 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com