Red fluorescent cadmium coordination polymer, preparation method and application thereof

A cadmium coordination polymer and a technology for coordination polymers, which are applied in the field of red fluorescent cadmium coordination polymers, can solve the problems of large differences in luminescence properties, unpredictability and the like, and achieve the effect that the preparation method is simple and feasible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of the coordination polymer of the present invention

[0037] Take the material according to the following specific mass or volume: Htpc (27.7mg, 0.1mmol), H 3 ntb(37.7mg,0.1mmol), Cd(NO 3 ) 2 ·4H 2 O(46.3mg, 0.15mmol), HNO 3 (30uL, 7mol / L, 0.21mmol), CH 3 CN(4mL), H 2 O (6mL).

[0038] Place the above materials in a 25mL reaction kettle, stir for 0.5h, and place the reaction system in a 160℃ constant temperature oven. After 5 days of reaction, cool to room temperature naturally. Red massive crystals are observed, which are filtered from the mother liquor and washed with distilled water , Naturally dry.

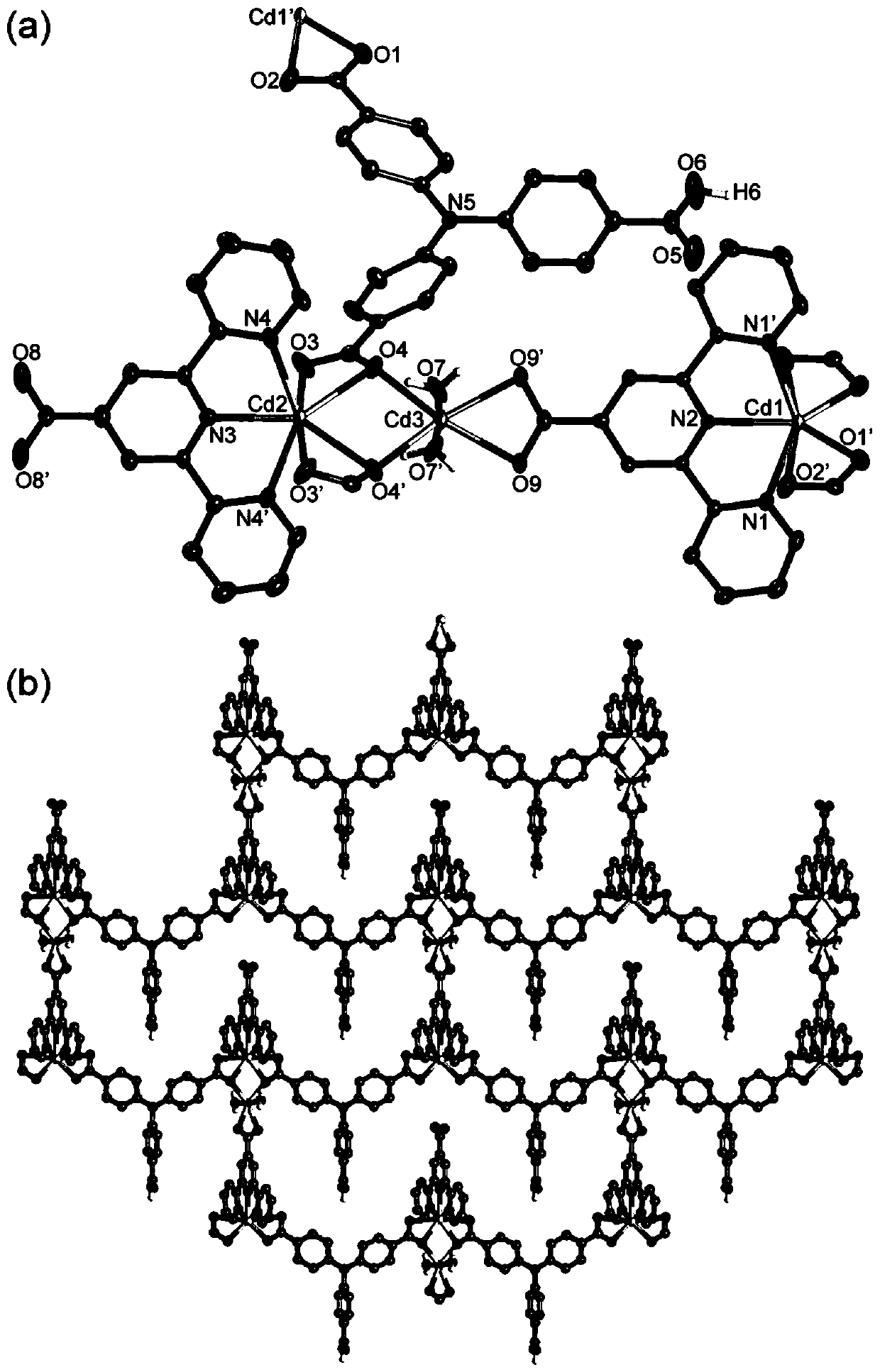

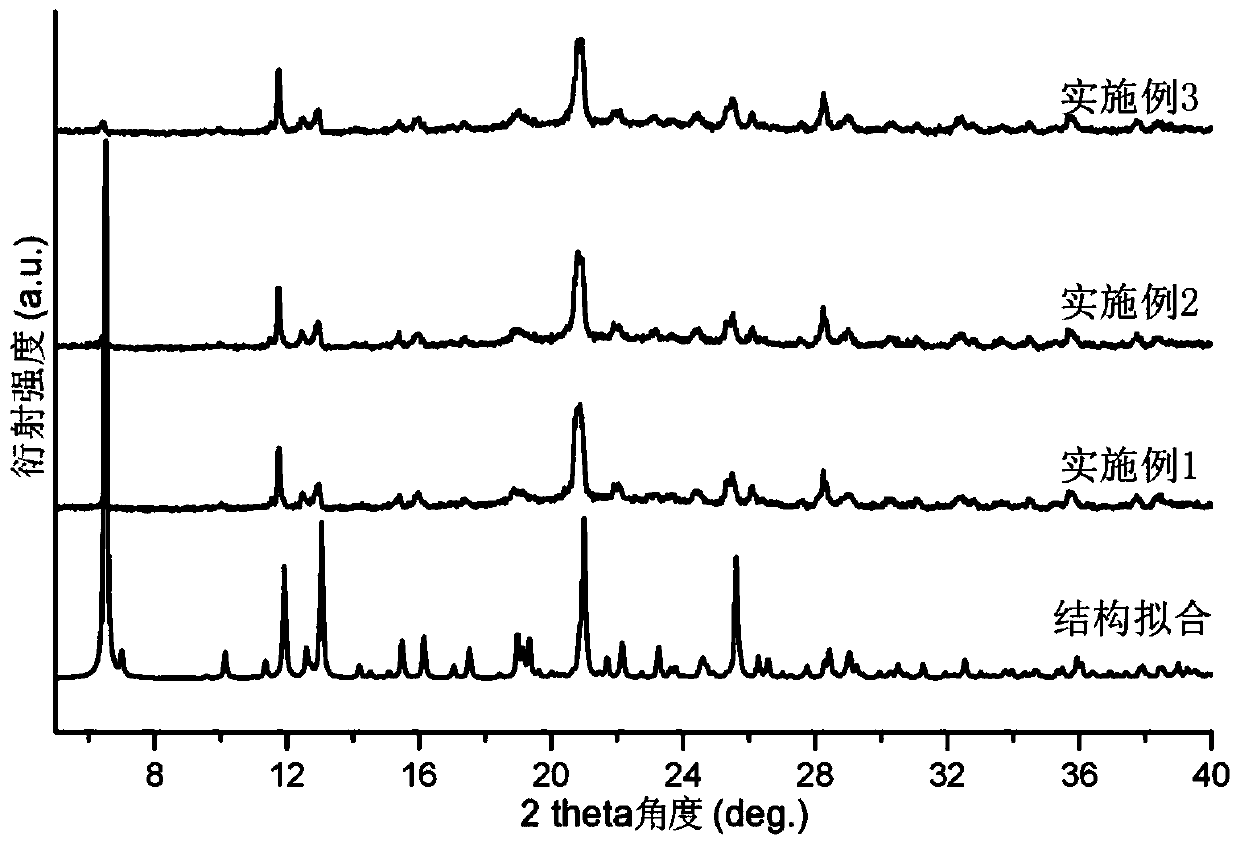

[0039] Perform X-ray single crystal diffraction analysis on the obtained target product to obtain its crystal structure ( figure 1 ). Bridging ligand tpc - (Formula III) and Hntb (Formula V) coordinately bond to Cd 2+ Ions form two-dimensional coordination polymers (attached figure 1 ), the structure contains a rare W-shaped macrocycle. The powder diff...

Embodiment 2

[0051] Example 2 Preparation of cadmium coordination polymer of the present invention

[0052] Take the material according to the following specific mass or volume: Htpc (27.7mg, 0.1mmol), H 3 ntb(37.7mg,0.1mmol), Cd(NO 3 ) 2 ·4H 2 O(30.8mg, 0.1mmol), HNO 3 (20uL, 7mol / L, 0.14mmol), CH 3 CN(2mL), H 2 O (8mL).

[0053] The above materials were placed in a 25mL reaction kettle, stirred for 0.5h, reacted in a constant temperature oven at 140°C for 5 days, and then cooled to room temperature naturally to obtain crystals, which were filtered from the mother liquor, washed with distilled water, and dried naturally.

[0054] The product was characterized by X-ray powder diffraction, and the data obtained was similar to that of Example 1, indicating that the crystal structure prepared in Example 2 did not change and the product was relatively pure.

[0055] Repeat this embodiment many times, and get {[Cd 3 (H 2 O) 2 (tpc) 2 (Hntb) 2 ](H 2 O)} n Based on the amount of Htpc, the calculated produ...

Embodiment 3

[0056] Example 3 Preparation of cadmium coordination polymer of the present invention

[0057] Take the material according to the following specific mass or volume: Htpc (27.7mg, 0.1mmol), H 3 ntb(11.3mg,0.03mmol), Cd(NO 3 ) 2 ·4H 2 O(61.7mg, 0.2mmol), HNO 3 (80uL, 7mol / L, 0.56mmol), CH 3 CN(5mL), H 2 O (5mL).

[0058] The above materials were placed in a 25mL reaction kettle, reacted in a constant temperature oven at 150°C for 6 days, and then naturally cooled to room temperature to obtain red crystals, which were filtered from the mother liquor, washed with distilled water, and naturally dried.

[0059] The product was characterized by X-ray powder diffraction, and the data obtained was similar to that of Example 1. It shows that the crystal structure obtained in Example 3 has not changed and the product is relatively pure.

[0060] Repeat this embodiment many times, and actually produce {[Cd 3 (H 2 O) 2 (tpc) 2 (Hntb) 2 ](H 2 O)} n Based on the amount of Htpc, the calculated produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com