Method for preparing canthaxanthin by electrocatalytic oxygen-oxidized beta-carotene

An electrocatalytic oxidation and carotene technology, applied in the field of nutritional chemicals, can solve the problems of unfriendly environment, low reaction yield and low yield, and achieve the effect of convenient use, high reaction yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

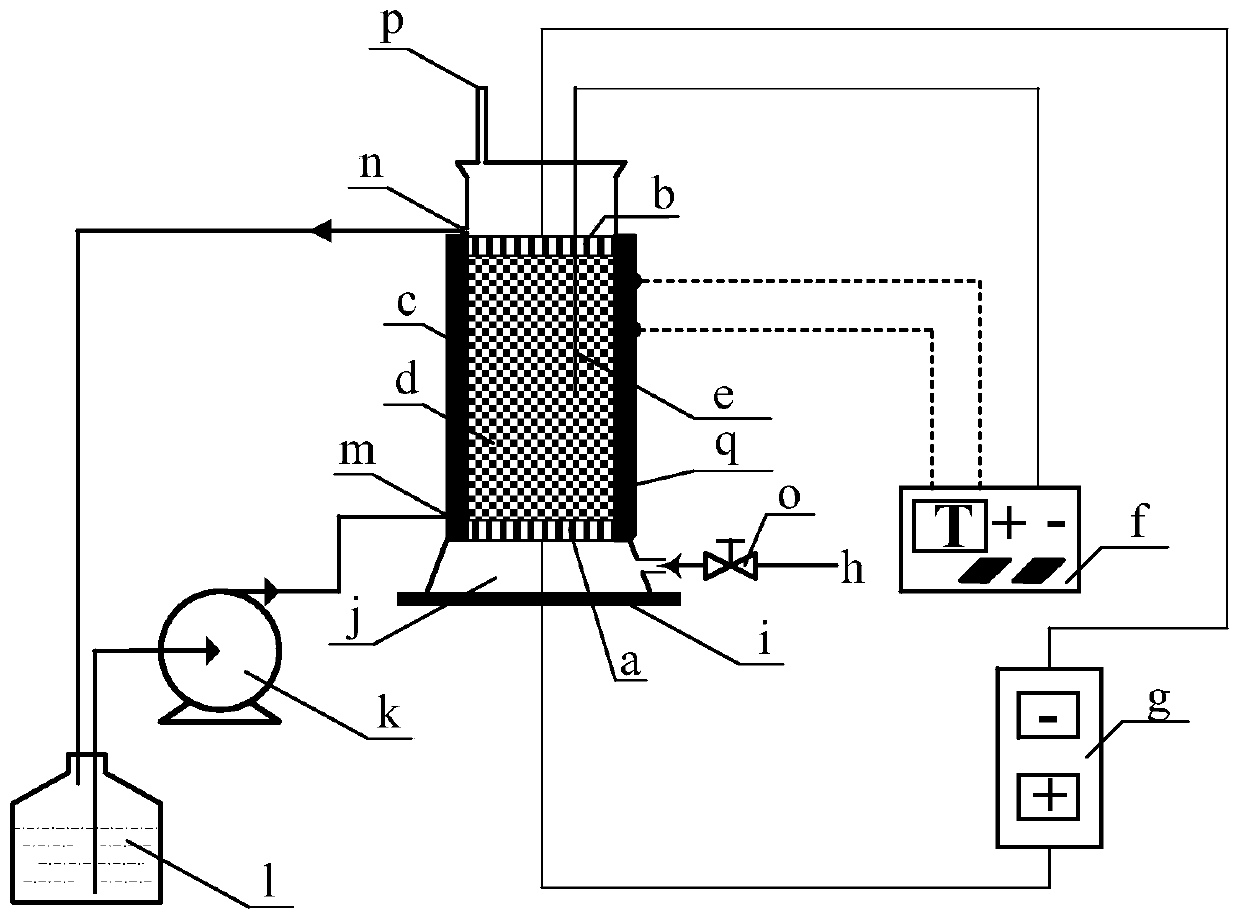

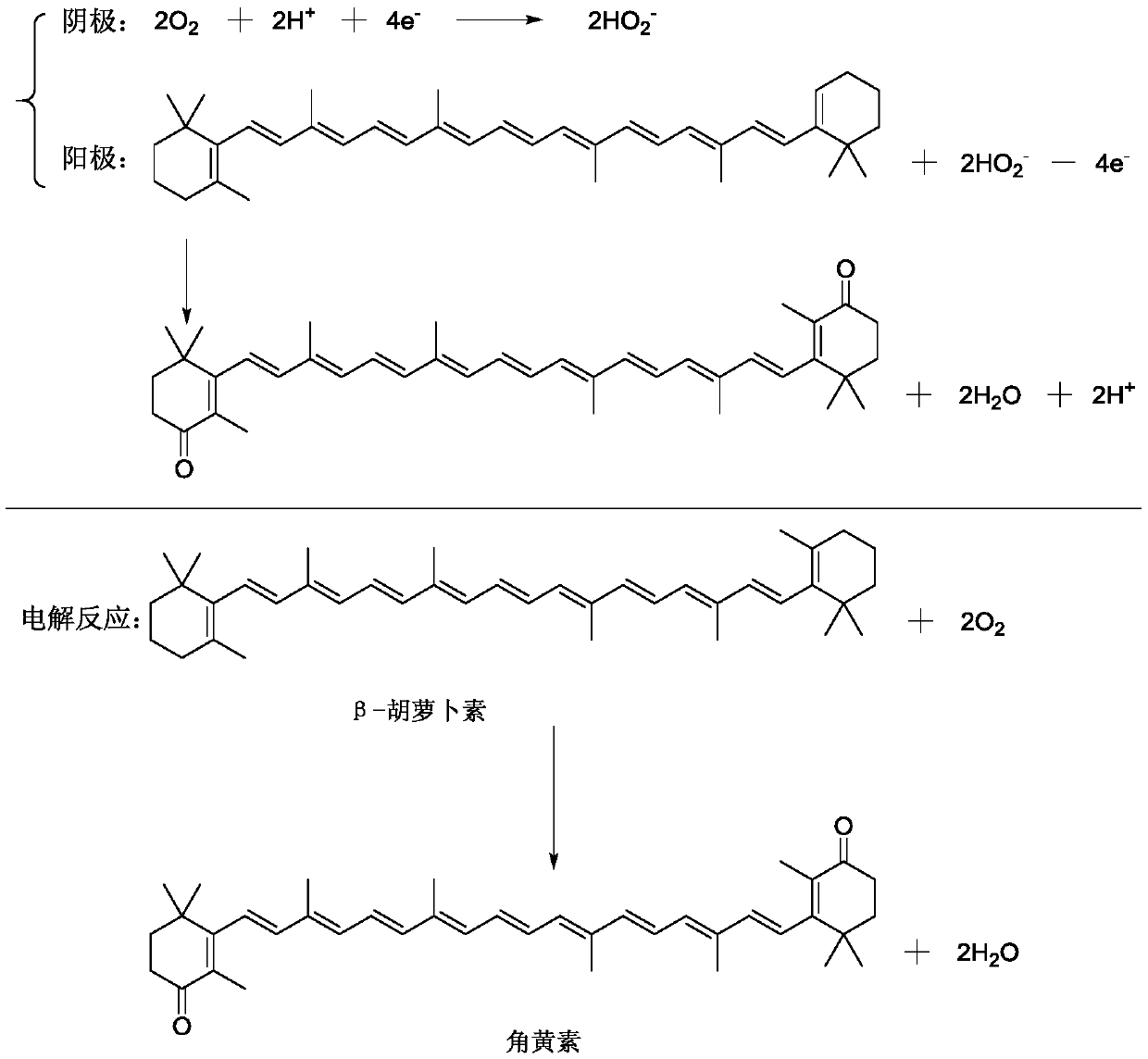

Method used

Image

Examples

Embodiment 1

[0046] 412g of graphene solid powder and 100g of kaolin solid powder were added to 1536g of methanol, and mixed system a was obtained after ultrasonic treatment for 3 hours. The solid after suction filtration of the mixed system a was dried at 65° C. for 2 hours, and then calcined at 850° C. for 10 hours in a nitrogen atmosphere to obtain a kaolin-graphene support. Weigh 6g and 135g of the chloroauric acid and copper nitrate solids and dissolve them in 705g of pure water, add the kaolin-graphene carrier obtained above and perform ultrasonic treatment for 3 hours to obtain the mixed system b. The mixed system b was transferred to a polytetrafluoro-lined autoclave for reaction at 110°C for 10 hours, and then at 160°C for 10 hours. Then dry at 100°C for 6h, and then bake at 850°C for 10h in a nitrogen atmosphere, and finally use a granulator to make Au-CuO / kaolin-graphene catalyst Cat1 with a particle size of 0.3mm. The Au content is 0.52wt%, the CuO content is 10.01wt%, and the...

Embodiment 2

[0048] 688g of graphene solid powder and 40g of kaolin solid powder were added to 2184g of n-propanol, and the mixed system a was obtained after ultrasonic treatment for 13h. The solid after the suction filtration of the mixed system a was dried at 100° C. for 8 hours, and then calcined at a high temperature of 1100° C. for 3 hours in a nitrogen atmosphere to obtain a kaolin-graphene support. Weigh 128g and 19g of the chloroauric acid and copper nitrate solids and dissolve them in 5145g of pure water, add the kaolin-graphene carrier obtained above and perform ultrasonic treatment for 13 hours to obtain the mixed system b. The mixed system b was transferred to a polytetrafluoro-lined autoclave for 50 hours at 160°C, and then at 260°C for 50 hours. Then it was dried at 140°C for 24h, and then calcined at 1100°C for 3h in a nitrogen atmosphere, and finally Au-CuO / kaolin-graphene catalyst Cat2 with a particle size of 1.25mm was made by a granulator. The Au content is 8wt%, the Cu...

Embodiment 3

[0050] 461g of graphene solid powder and 85g of kaolin solid powder were added to 1638g of methanol, and mixed system a was obtained after ultrasonic treatment for 5h. The solid after suction filtration of the mixed system a was dried at 75° C. for 3 hours, and then calcined at a high temperature of 900° C. for 8 hours in a nitrogen atmosphere to obtain a kaolin-graphene support. Weigh 24g and 115g of the chloroauric acid and copper nitrate solids and dissolve them in 1390g of pure water, add the kaolin-graphene carrier obtained above and perform ultrasonic treatment for 5 hours to obtain the mixed system b. The mixed system b was transferred to a polytetrafluoro-lined autoclave for 20 h at 120 °C, and then at 180 °C for 20 h. Then dry at 110°C for 10h, then bake at 900°C for 8h in a nitrogen atmosphere, and finally use a granulator to make Au-CuO / kaolin-graphene catalyst Cat3 with a particle size of 0.6mm. The Au content is 1.98wt%, the CuO content is 8.04wt%, and the graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com