Titanium dioxide synthetic system

A technology of titanium dioxide and titanium tetrachloride, which is applied in the field of metallurgy, can solve problems such as non-environmental protection, and achieve the effects of improving environmental protection, easy operation, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

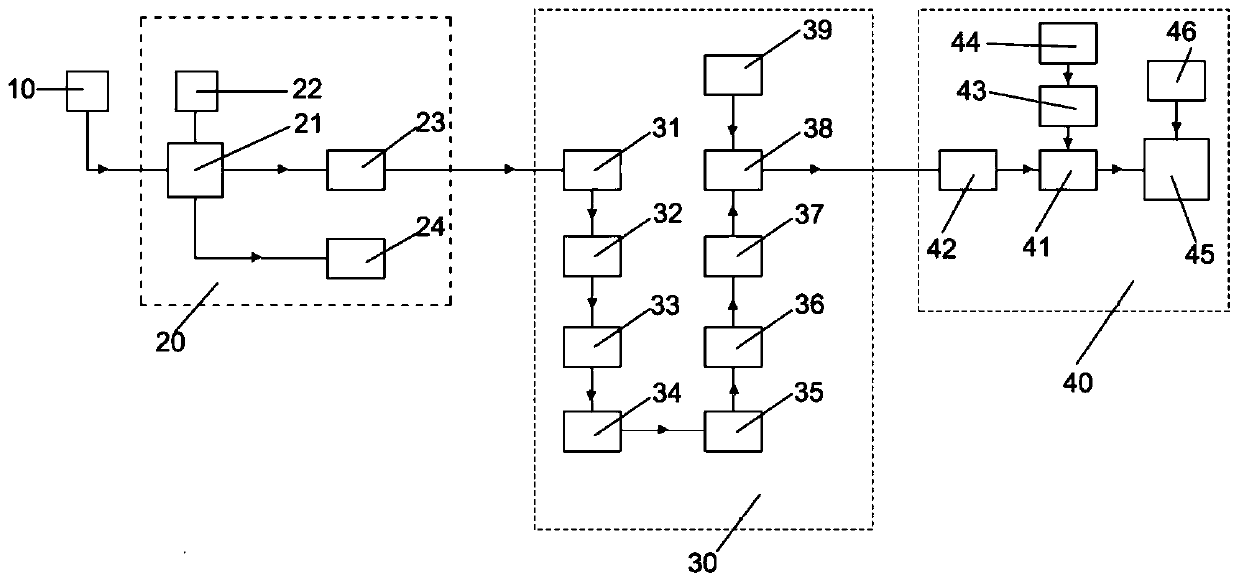

[0048] use figure 1 The apparatus shown produces titanium dioxide.

[0049] Ilmenite and coke are reduced and smelted according to the mass ratio of 7:1 to obtain titanium-rich slag and iron metal phase. The smelting flue gas is burned by the waste heat boiler to produce steam, and the combustion flue gas is cooled to 170°C and collected by the bag dust collector Dust up to standard discharge. The titanium content in the titanium-rich slag is 93wt%, and the titanium recovery rate is 98%.

[0050] Titanium-rich slag and coke are mixed with chlorine gas at a mass ratio of 3:1 to undergo a chlorination reaction in a fluidized bed reactor. The reaction temperature of the chlorination reaction is 950-1050°C, and the reaction pressure is 110-150KPa. The mixed gas containing titanium tetrachloride produced by the reaction is quenched and rinsed, dedusted, cooled and condensed to obtain a crude titanium tetrachloride liquid product. The yield of the chlorination reaction was 95%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com