Diamond abrasive belt, device for fast grinding monocrystal silicon rod outer circle and method for fast grinding monocrystal silicon rod outer circle

A technology of diamond sand and single crystal silicon rod, applied in the field of abrasive tool grinding, can solve problems such as excessively hard diamond grinding wheel, and achieve the effect of improving life, good finish and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A diamond abrasive belt, comprising the following manufacturing steps:

[0044] Step 1, making a mold that engraves blind holes arranged in an orderly manner, and the hole depth and diameter of all blind holes are the same;

[0045] Step 2, mixing the diamond powder and the resin bond evenly into the blind hole of the mould;

[0046] Step 3, the mold in which diamond powder and resin binder are added in step 2 is attached to the fiber base cloth 1, pressurized and heated, and demoulded.

[0047] A device for quickly grinding the outer circle of a single crystal silicon rod, comprising a frame 7, on which more than one diamond abrasive belt produced by the above-mentioned manufacturing method is arranged, the diamond abrasive belt is ring-shaped and driven by a driving mechanism 13 to rotate at a high speed; The frame 7 is also provided with an inner guide wheel 6 and an outer guide wheel 4 for supporting the single crystal silicon rod and moving the single crystal sili...

Embodiment 2

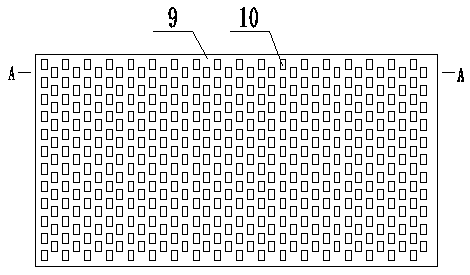

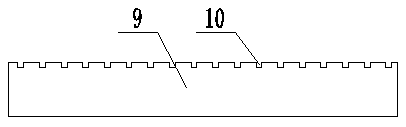

[0054] Such as Figure 1-3 Shown, a kind of diamond abrasive belt is made through the following steps:

[0055]Step 1, making a steel mold 9 engraving orderly arranged blind holes, all the blind holes 10 have the same size, and the blind holes 10 have a depth of 1 mm, a length of 3 mm, and a width of 1.5 mm.

[0056] In step 2, the diamond powder and the resin bond are evenly mixed and put into the blind hole 10 of the steel mold 9 .

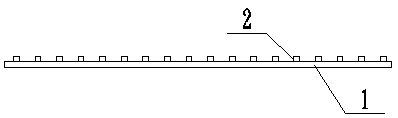

[0057] Step 3, the steel mold 9 with diamond powder and resin binder added in step 2 is attached to the fiber base cloth 1 with a thickness of 1.5mm, and kept at a temperature of 130°C and a pressure of 10MPa for 20 minutes, and the thickness of the demoulded diamond is about 1.0mm diamond abrasive belt 5.

[0058] Such as Figure 4 and Figure 5 As shown, a device for quickly grinding the outer circle of a single crystal silicon rod includes a frame 7, and the frame 7 is provided with three diamond abrasive belts 5 made by the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com