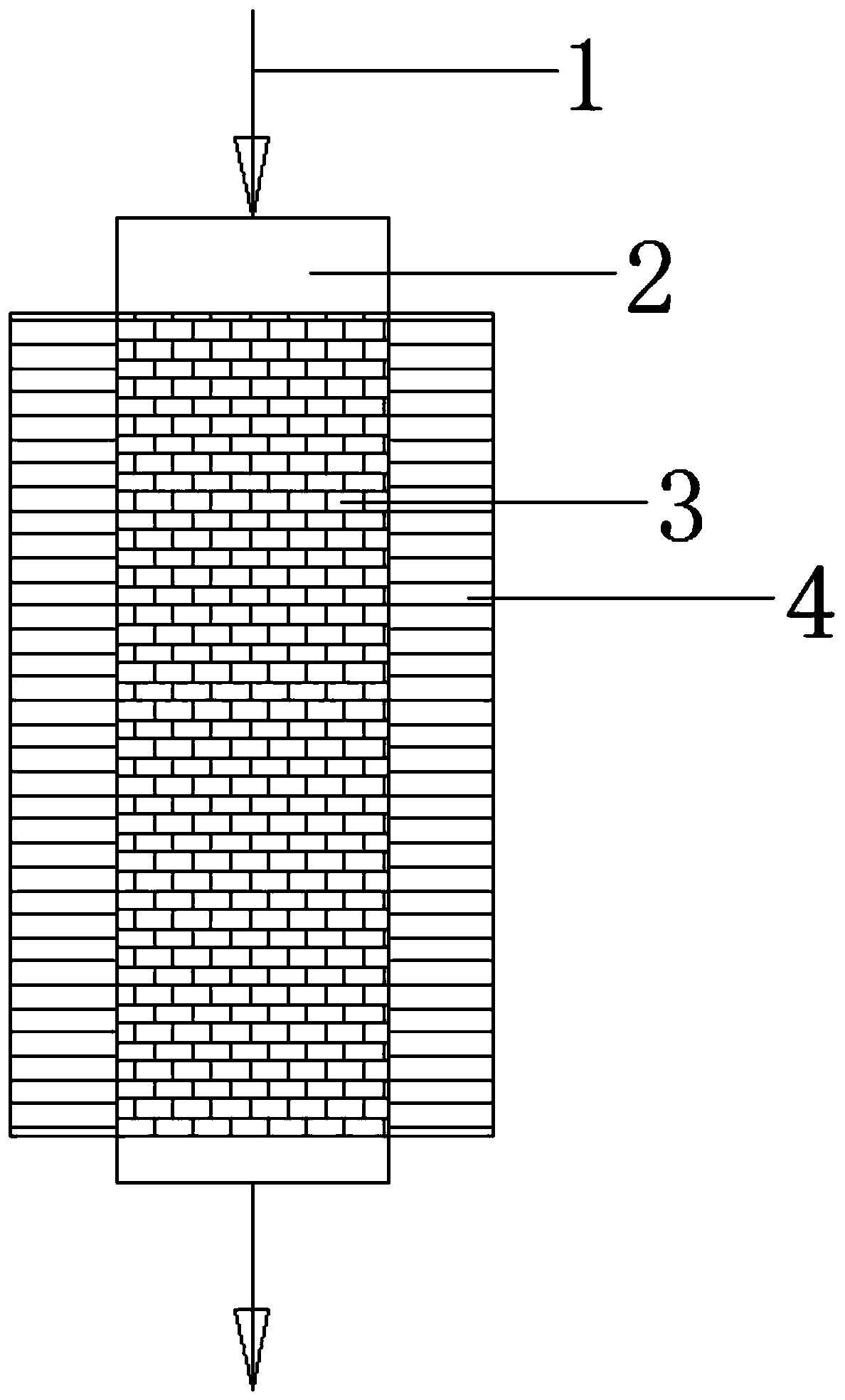

Catalyst carrier with three-dimensional mesh inert skeleton structure and preparation method of catalyst carrier

A catalyst carrier, three-dimensional network technology, applied in the direction of catalyst carrier, catalyst activation/preparation, catalyst protection, etc., can solve the problem of rapid decline in porosity and pore size distribution, affecting catalyst use cost and other issues, to achieve good heat storage and heat conduction capacity, which is conducive to long-term maintenance, and is not easy to migrate or collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Select a kind of activated clay ore (composed of various types of silicate) as raw material, aluminum sol and ethanol as binder, glycerin as lubricant, Tianqing powder as pore-forming agent, according to active clay ore: aluminum sol: The ratio of ethanol: glycerol: Tianqing powder: water is 100:15:3:67:15:16 to form a mixture, and then the mixture is fully kneaded with a kneader, and after kneading, extrude it with a butterfly mold with a diameter of 1.2 to 1.8 mm butterfly bar. Then the drying conditions of the prepared butterfly strips are temperature 80°C and drying time 60h. After the water content is less than 10%, put the butterfly strips into a heating container filled with nitrogen, and gradually heat up to 850°C, stop heating after 4 hours of constant temperature, naturally cool down to 450°C constant temperature, then gradually introduce oxygen to replace part of the nitrogen in the heating container, control the oxygen concentration in the heating container ...

Embodiment 2

[0062] Select macroporous alumina powder as raw material, paraffin as binder, talcum powder as lubricant, and cellulose methyl ether as pore-forming agent, according to the ratio of macroporous alumina: paraffin: talcum powder: cellulose methyl ether: water 100 : 5: 10: 65: 20 to form a mixture, and then the mixture is fully kneaded with a kneader, and after kneading, a clover-shaped strip with a diameter of 2-3 mm is extruded with a clover mold. Then the drying conditions of the obtained clover strips are temperature 50°C and drying time 36h. After the water content is less than 10%, put the clover strips into a heating container filled with nitrogen, and gradually raise the temperature to 1200°C at a heating rate of 30°C / h , stop heating after constant temperature for 5 hours, naturally cool down to 400°C constant temperature, then gradually introduce oxygen to replace part of the nitrogen in the heating container, control the oxygen concentration in the heating container at ...

Embodiment 3

[0070] Select pseudo-boehmite powder and silicon dioxide powder as raw materials, dry starch and nitric acid as binder, Tianqing powder as lubricant, and polyacryl alcohol as pore-forming agent, according to pseudo-boehmite: silicon dioxide: The ratio of dry starch: nitric acid: Tianqing powder: polypropylene alcohol: water is 50:50:9:1:5:85:20 to form a mixture, and then the mixture is fully kneaded with a kneader, and after kneading, use a cylindrical mold Cylindrical shaped bars with a diameter of 2 to 3 mm were extruded. Then the drying conditions of the prepared cylindrical strips are temperature 75°C, drying time 48h, after the water content is less than 10%, put the cylindrical strips into a heating container filled with nitrogen, and gradually increase the temperature at a heating rate of 40°C / h To 2200°C, stop heating after 10 hours of constant temperature, naturally cool down to 500°C constant temperature, then gradually introduce oxygen to replace the nitrogen in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com