High-conductivity high-strength aluminum alloy and preparation method thereof

A technology of aluminum alloy and aluminum alloy ingot casting, which is applied in the field of aluminum alloy, can solve the problems of low strength, low thermal conductivity, and high strength, and achieve the effects of refining grains, eliminating influence, and avoiding polymerization failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

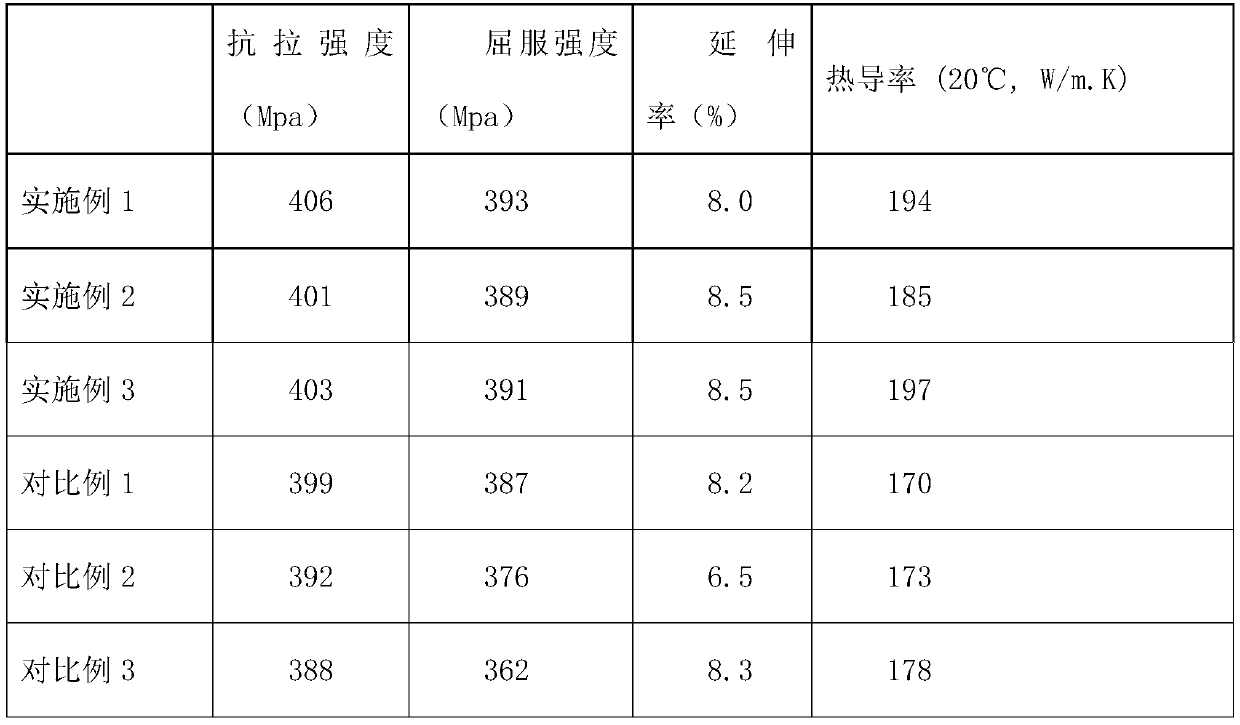

Examples

Embodiment 1

[0041] The composition of a high-conductivity and high-strength aluminum alloy: Si is 0.74%, Mg is 0.92%, Fe is 0.08%, Cu is 0.67%, Mn is 0.08%, B is 0.023%, Cr is 0.0020%, and Ti is 0.0040%. Other single ≤0.03%, total ≤0.15%, the balance is Al.

[0042] A method for manufacturing a high-conductivity high-strength aluminum alloy, comprising the following steps:

[0043] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0044] (2) Heating the aluminum ingot to 760° C. for melting, then adding magnesium ingot and master alloy, wherein, boron adopts B3 master alloy; stirring and melting to obtain aluminum alloy liquid I;

[0045] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0046] (4) Put the aluminum alloy liquid II into the launder, and then...

Embodiment 2

[0052] The composition of a high-conductivity and high-strength aluminum alloy: Si is 0.60%, Mg is 0.95%, Fe is 0.13%, Cu is 0.75%, Mn is 0.12%, B is 0.014%, Cr is 0.0010%, and Ti is 0.0080%. Other single ≤0.03%, total ≤0.15%, the balance is Al.

[0053] A method for manufacturing a high-conductivity high-strength aluminum alloy, comprising the following steps:

[0054] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0055] (2) Heating the aluminum ingot to 760° C. for melting, then adding magnesium ingot and master alloy, wherein, boron adopts B3 master alloy; stirring and melting to obtain aluminum alloy liquid I;

[0056] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0057] (4) Put the aluminum alloy liquid II into the launder, and then...

Embodiment 3

[0063] The composition of a high-conductivity and high-strength aluminum alloy: Si is 0.80%, Mg is 0.85%, Fe is 0.10%, Cu is 0.55%, Mn is 0.08%, B is 0.037%, Cr is 0.0010%, and Ti is 0.0010%. Other single ≤0.03%, total ≤0.15%, the balance is Al.

[0064] A method for manufacturing a high-conductivity high-strength aluminum alloy, comprising the following steps:

[0065] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0066] (2) Heating the aluminum ingot to 760° C. for melting, then adding magnesium ingot and master alloy, wherein, boron adopts B3 master alloy; stirring and melting to obtain aluminum alloy liquid I;

[0067] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0068] (4) Put the aluminum alloy liquid II into the launder, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com