Preparation method of adhesive for shoe materials

A technology for adhesives and shoe materials, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of poor waterproof performance and bonding performance, and achieve good waterproof performance, good bonding performance, transparency and The effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

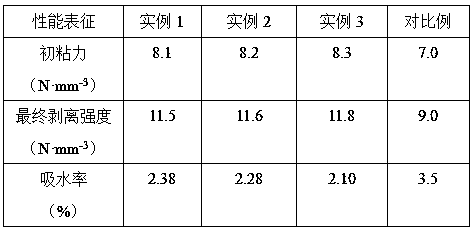

Examples

example 1

[0025]Take epoxy resin, curing agent polyisocyanate crosslinking agent, absolute ethanol, sodium dodecylbenzenesulfonate, triethylenetetramine, and mix epoxy resin, triethylenetetramine and absolute ethanol evenly, that is, Emulsion, adding curing agent polyisocyanate type crosslinking agent and sodium dodecylbenzenesulfonate to the emulsion, stirring and dispersing treatment to obtain a mixed emulsion, subjecting the mixed emulsion to heat preservation reaction, cooling to room temperature to obtain a suspension, Carry out suction filtration of the suspension to obtain a filter residue, wash the filter residue, dry it, and cool it to room temperature to obtain a modified curing agent; water-based polyurethane emulsion, neoprene emulsion, modified curing agent, composite surface Active agent, mix water-based polyurethane emulsion and neoprene emulsion, and conduct high-speed stirring treatment to obtain a composite emulsion, add modified curing agent and composite surfactant to...

example 2

[0027] Take epoxy resin, curing agent polyisocyanate crosslinking agent, absolute ethanol, sodium dodecylbenzenesulfonate, triethylenetetramine, and mix epoxy resin, triethylenetetramine and absolute ethanol evenly, that is, Emulsion, adding curing agent polyisocyanate type crosslinking agent and sodium dodecylbenzenesulfonate to the emulsion, stirring and dispersing treatment to obtain a mixed emulsion, subjecting the mixed emulsion to heat preservation reaction, cooling to room temperature to obtain a suspension, Carry out suction filtration of the suspension to obtain a filter residue, wash the filter residue, dry it, and cool it to room temperature to obtain a modified curing agent; water-based polyurethane emulsion, neoprene emulsion, modified curing agent, composite surface Active agent, mix water-based polyurethane emulsion and neoprene emulsion, and conduct high-speed stirring treatment to obtain a composite emulsion, add modified curing agent and composite surfactant t...

example 3

[0029] Take epoxy resin, curing agent polyisocyanate crosslinking agent, absolute ethanol, sodium dodecylbenzenesulfonate, triethylenetetramine, and mix epoxy resin, triethylenetetramine and absolute ethanol evenly, that is, Emulsion, adding curing agent polyisocyanate type crosslinking agent and sodium dodecylbenzenesulfonate to the emulsion, stirring and dispersing treatment to obtain a mixed emulsion, subjecting the mixed emulsion to heat preservation reaction, cooling to room temperature to obtain a suspension, Carry out suction filtration of the suspension to obtain a filter residue, wash the filter residue, dry it, and cool it to room temperature to obtain a modified curing agent; water-based polyurethane emulsion, neoprene emulsion, modified curing agent, composite surface Active agent, mix water-based polyurethane emulsion and neoprene emulsion, and conduct high-speed stirring treatment to obtain a composite emulsion, add modified curing agent and composite surfactant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com