A three-dimensional composite material and its preparation method, application, substrate and electronic device

A composite material and three-dimensional technology, which is applied in the fields of three-dimensional composite materials and their preparation, substrates and electronic devices, can solve the problems of not effectively increasing the thermal conductivity of composite materials, increasing the dielectric constant of composite materials, and deteriorating the mechanical properties of materials. Achieve the effect of facilitating large-scale production, enhancing mutual contact, and requiring less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

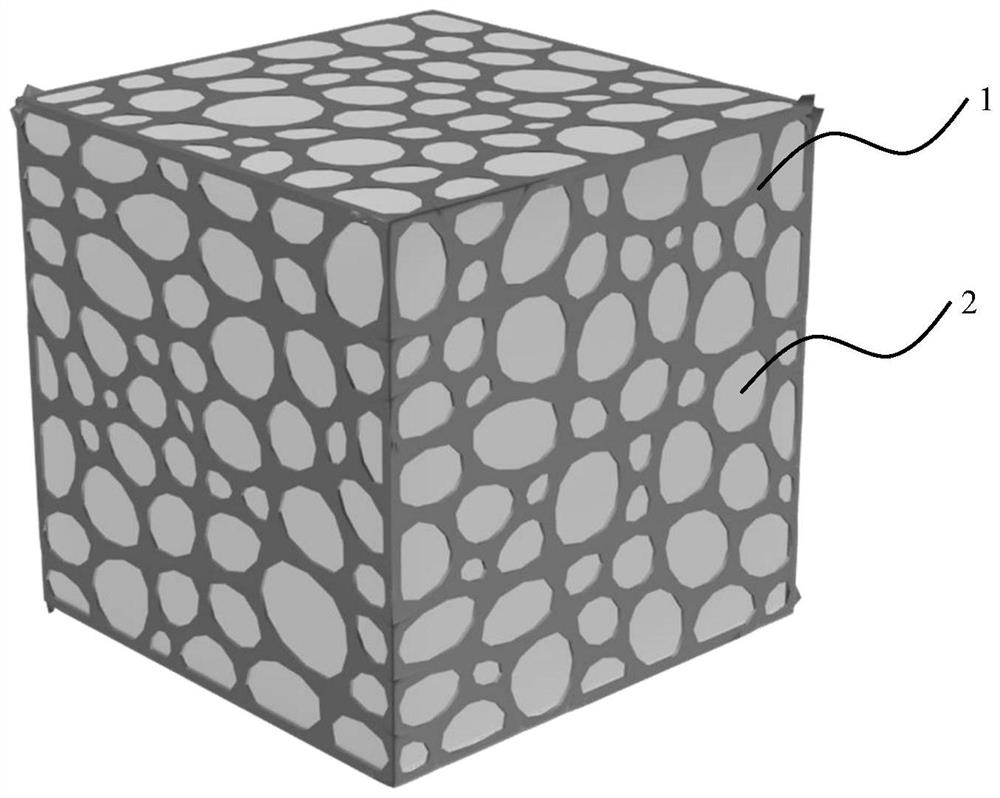

[0037] figure 1 It is a schematic structural diagram of a three-dimensional composite material according to an embodiment of the present invention. like figure 1 As shown, the three-dimensional composite material includes a thermally conductive filler BN as the three-dimensional network skeleton 1 and a polymer 2 filled in the three-dimensional network skeleton 1. In this embodiment, the polymer 2 is epoxy resin.

[0038] The preparation method of the three-dimensional composite material is as follows:

[0039] 1) Mix BN powder with an average particle size of 3 μm and PVA with an average particle size of 160 μm at room temperature according to the required volume fraction;

[0040] 2) Press the uniformly mixed PVA and BN powders into a tablet under 300MPa for 5min in a tablet press;

[0041] 3) heat treatment of the sheet material obtained in step 2) at 700° C. for 10 h to decompose the PVA to obtain a three-dimensional network skeleton of BN, which can be self-supporting ...

Embodiment 2

[0044] A three-dimensional composite material, the thermally conductive filler is diamond, and the filled polymer is PDMS silicone rubber.

[0045] The preparation method of the three-dimensional composite material is as follows:

[0046] 1) Mix the diamond powder with an average particle size of 3 μm and the camphor with an average particle size of 500 μm at room temperature according to the required volume fraction;

[0047] 2) Press the uniformly mixed camphor and diamond powder into a tablet shape under 10MPa pressure for 30min in a tablet press;

[0048] 3) heat treatment of the sheet material obtained in step 2) at 200° C. for 12 hours to decompose the camphor to obtain a three-dimensional network skeleton of diamond;

[0049] 4) The three-dimensional network skeleton obtained in step 3) is placed in a polytetrafluoroethylene mold and filled with PDMS silicone rubber, placed in a vacuum oven to remove air bubbles for 0.5h and then cured. The curing program is 60°C / 4h. ...

Embodiment 3

[0051] A three-dimensional composite material such as figure 1 As shown, the thermally conductive filler is AlN, and the filled polymer is epoxy resin.

[0052] The preparation method of the three-dimensional composite material is as follows:

[0053] 1) Mix AlN powder with an average particle size of 50 μm and PC with an average particle size of 500 μm at room temperature according to the required volume fraction;

[0054] 2) Press the uniformly mixed PC and AlN powder into a tablet shape under 500MPa for 3min in a tablet press;

[0055] 3) heat treatment of the sheet material obtained in step 2) at 1000° C. for 7 h to decompose PC to obtain a three-dimensional network skeleton of AlN;

[0056] 4) The three-dimensional network skeleton obtained in step 3) is placed in a polytetrafluoroethylene mold and filled with bisphenol A epoxy resin, methyl hexahydrophthalic anhydride is selected as a curing agent, and imidazole is used as an accelerator. Placed in a vacuum oven to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com