Workpiece surface defect feature extraction method

A workpiece surface and feature extraction technology, applied in the direction of optical testing flaws/defects, computer components, image data processing, etc., to achieve the effects of easy understanding, image quality improvement, and complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A feature extraction method for workpiece surface defects, comprising the following steps:

[0042] (1) Source image acquisition: use professional imaging equipment to collect workpiece surface images;

[0043] (2) Source image preprocessing: improve image quality and image contrast;

[0044] (3) After removing the noise in the source image, the gray histogram is counted to obtain two maximum values of image foreground and background gray, and the gray stretching algorithm is used to obtain the gray stretched image;

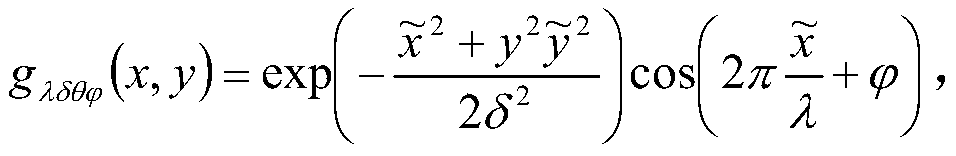

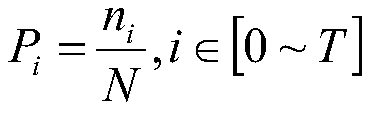

[0045] The grayscale stretching algorithm is calculated by the following formula:

[0046]

[0047] Among them, the gray level of the source image is 0~M, the background color is white, and the foreground color is black, a is the gray value corresponding to the maximum value of the foreground of the gray histogram in 0~M / 2, b is the gray value in M The gray value corresponding to the maximum value of the gray histogram background in / 2~M, x, y are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com