Nodular cast iron section bar capable of improving fracture toughness and technology

A ductile iron and fracture toughness technology, which is applied in the process field of ductile iron profiles, can solve the problems of poor fracture toughness and other problems, and achieve the effects of avoiding crack initiation, high roundness and large quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A ductile iron profile with improved fracture toughness, the mass percentage ranges of carbon, silicon, manganese, sulfur, phosphorus and bismuth in the ductile iron profile are: carbon: 3.45%-3.55%; silicon: 2.55%-2.65 %; Manganese: 0.15%-0.25%; Sulfur: 0.009%-0.011%; Phosphorus: 0.030%-0.034%; Bismuth: 0.009%-0.0011%; the rest is iron. The graphite balls in the structure of the ductile iron profile are small and numerous, and have high roundness. The round and fine graphite balls have relaxation stress, which can delay the expansion of cracks and achieve the effect of avoiding crack initiation.

[0046] Based on the above components and mass percentage ranges, a ductile iron profile with improved fracture toughness is selected and produced, wherein the mass percentages of carbon, silicon, manganese, sulfur, phosphorus and bismuth are respectively: carbon: 3.50%; silicon: 2.60; manganese: 0.22%; Sulfur: 0.010%; Phosphorus: 0.032%; Bismuth: 0.01%; the rest is...

Embodiment 2

[0047] Example 2: Select and produce a ductile iron profile (QT400 material) that improves fracture toughness. Choose to produce on the No. 3 line of Hebei Henggong Machinery Equipment Technology Co., Ltd., three production lines are produced at the same time, and a trace amount of metal bismuth is added in the spheroidization process to refine the shape of graphite, increase the number of graphite balls, and reduce the diameter of graphite. Include the following steps:

[0048] (1) For the smelting of molten iron, a 6-ton and a 10-ton intermediate frequency induction furnace is used to smelt the molten iron. The weight of the molten iron is 1.6-1.7 tons / bag, according to the mass ratio of pig iron Q10: scrap steel: returned rod / The iron filings are weighed at 20:65:15 and the ingredients after the furnace are weighed. The molten iron formed after smelting the ingredients after the furnace contains less sulfur. Due to the ductile iron containing sulfur, it is easy to make th...

Embodiment 3

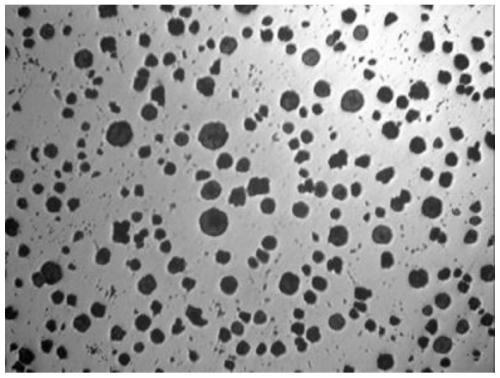

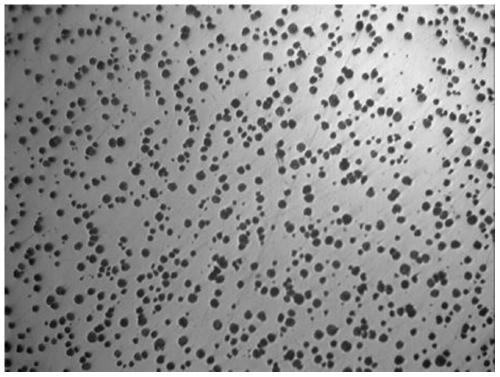

[0056] Intercept the QT400 material produced in Example 2 Nodular cast iron section, observe the metallographic structure of the section under a microscope of 100 times, and obtain the metallographic structure image 3 , and the microstructure of the fractured ductile iron without adding pure metal bismuth figure 2 contrast, from figure 2 and 3 The comparison shows: figure 2 The number of graphite balls is small, the graphite balls are larger, and the graphite grade is grade 5, that is, the diameter of the graphite balls is about 6-12mm. and image 3 The number of graphite balls increased significantly, the graphite balls are smaller, the graphite grade is 7, that is, the diameter of the graphite balls is about 1.5-3mm, the matrix structure is uniformly refined, and the graphite grade is significantly improved. Therefore, the matrix structure of the ductile iron profile added with pure metal bismuth has a better stress relaxation effect, which slows down the propagati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com