Damp and heat resistant electromagnetic shielding film, composite material, preparation method and application

A technology of electromagnetic shielding and composite materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve problems such as difficult processing, corrosion and damage of metal materials, poor mechanical properties of films, etc., to achieve enhanced mechanical properties and electrical conductivity, high electromagnetic Effect of shielding performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Another aspect of the embodiments of the present invention provides a method for preparing a heat and humidity resistant electromagnetic shielding film, which includes:

[0049] Provide carbon nanotube films;

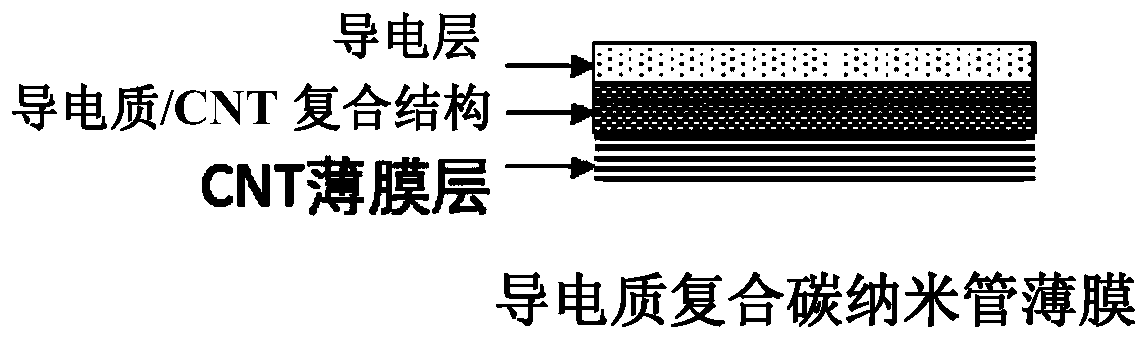

[0050] Depositing a conductive layer on the surface of the carbon nanotube film,

[0051] And by controlling the structure of the carbon nanotube film and the deposition parameters of the conductive layer, a conductive / carbon nanotube composite structure is formed between the carbon nanotube film and the conductive layer to obtain a conductive composite carbon nanotube film.

[0052] In some preferred embodiments, the preparation method includes: preparing the carbon nanotube thin film by at least any one of floating catalytic chemical vapor deposition, vacuum filtration, coating, and 3D printing.

[0053] Further, the thickness of the carbon nanotube film layer is above 0.1 μm.

[0054] In some preferred embodiments, the preparation method includes: at least d...

Embodiment 1

[0083] A carbon nanotube film with a thickness of 3 μm was obtained by floating catalytic chemical vapor deposition, and a single-sided copper layer was plated on the surface of the CNT film by magnetron sputtering. Adjust the distance between the target and the CNT film, set the speed of the sample holder to 20r / min, so that Cu can be evenly sputtered onto the CNT film. Pump the vacuum of the instrument body to 8×10 -4 Pa, and high-purity argon gas was introduced, and the gas flow rate was adjusted to 20 sccm for pre-sputtering for 5 minutes to effectively remove impurities on the surface of the Cu target. The sputtering power of Cu is 200W, and the sputtering pressure is 0.3Pa. Respectively control the sputtering time to be 450s to obtain a CNT composite film with a Cu layer thickness of 0.4 μm, a Cu / CNT composite structure of 0.2 μm, and a Cu composite carbon nanotube film (Cu layer-Cu / CNT composite structure-CNT film layer). By adjusting different deposition times, such...

Embodiment 2

[0087] The CNT film is prepared by vacuum filtration method with a thickness of 10 μm, and a layer of silver film is covered on the surface of the film by vacuum evaporation method. By adjusting the evaporation temperature of 700-1200°C and the time of 10-1000s, the CNT / Ag composite structure and the Ag layer are adjusted. The thickness of the Ag layer is 0.1 μm, and the Ag / CNT composite structure is 0.5 μm. Then cover SiO on the surface of CNT / Ag by coating method 2 Protective layer with a thickness of 50 μm, cured to obtain CNT / Ag / SiO 2 Composite film. The shielding effect of the composite film reaches 100dB, the tensile strength is increased by 70%, and the shielding effect is not lower than 80dB for 40 days in an environment with a humidity of 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com