Connecting material for being connected with silicon carbide material and application of connecting material

A technology for connecting materials and silicon carbide, applied in the composite field, can solve problems such as difficulty in meeting actual use requirements, and achieve the effect of achieving local seamless connection, similar macro performance, and promoting connection and densification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

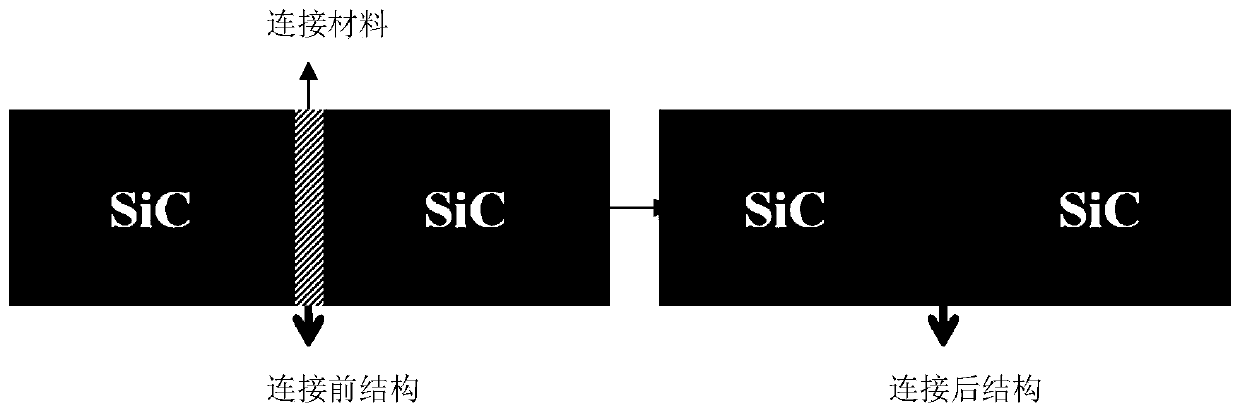

[0063] In this example, if figure 1 Shown is a schematic diagram of the connection structure of 500 nm Er-bonded SiC ceramics. The material to be connected is two Ф20×20mm silicon carbide, the material of the connection layer is 500nm Er, and the connection interface is assisted by electric field heating to make the connection interface reach 1900°C, so as to connect the SiC materials to be connected together. Specific steps are as follows:

[0064] (1) Polish the surface of silicon carbide to be connected to 1 μm with diamond polishing liquid to remove surface defects and impurities;

[0065] (2) Coating a 500nm Er film on the surface of a piece of silicon carbide to be connected by physical vapor deposition, and then connecting another piece of silicon carbide to its surface; then put the sample into a graphite mold, and then place the graphite mold in a spark plasma sintering furnace In the process, current is applied, and the temperature is raised to 1900°C at a heating ...

Embodiment 2

[0069] In this example, if figure 1 Shown is a schematic diagram of the connection structure of 500nm Dy-bonded SiC ceramics. The material to be connected is two Ф30×30mm silicon carbide, and the material of the connection layer is a 500nm Dy film. The connection interface is assisted by electric field heating to make the connection interface reach 1900°C, thereby connecting the SiC materials to be connected together. Specific steps are as follows:

[0070] (1) Polish the surface of silicon carbide to be connected to 1 μm with diamond polishing liquid to remove surface defects and impurities;

[0071] (2) Use physical vapor deposition to coat a 500nm Dy film on the surface of a silicon carbide to be connected, and then connect another silicon carbide to its surface; then put the sample into a graphite mold, and then place the graphite mold in a spark plasma sintering furnace During the heating process, the current is applied, and the temperature is raised to the furnace temp...

Embodiment 3

[0075] In this example, if figure 1 Shown is a schematic diagram of the connection structure of 500nm Er-coated SiC composite material connected to SiC ceramics. The materials to be connected are two Ф20×20mm silicon carbide, and the connection layer material is 500nm Er-coated silicon carbide composite material. The connection interface is assisted by electric field heating to make the connection interface reach 1600°C, so that the SiC materials to be connected are connected together . Specific steps are as follows:

[0076] (1) Polish the surface of silicon carbide to be connected to 1 μm with diamond polishing liquid to remove surface defects and impurities;

[0077] (2) Prepare 500nm Er-coated silicon carbide composite material by molten salt method, and make a casting film, sandwich the 500nm Er-coated silicon carbide composite material casting film between two pieces of silicon carbide, and then place the sample Put the graphite mold into the graphite mold, then place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com