Microfluidic chip, microfluidic system and infrared microfluidic analysis method

A microfluidic chip and microfluidic system technology, applied in the field of microfluidics, can solve problems such as difficult to meet the size, unable to control the temperature of the liquid pool, unable to exchange and circulate the liquid, etc., to achieve easy calibration, shorten the vertical height, and avoid errors the effect of existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

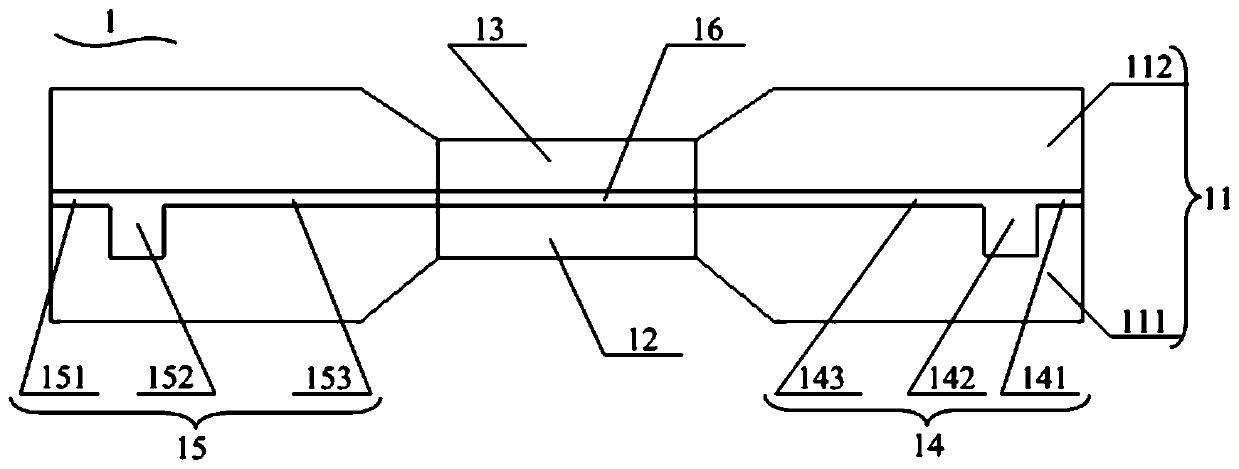

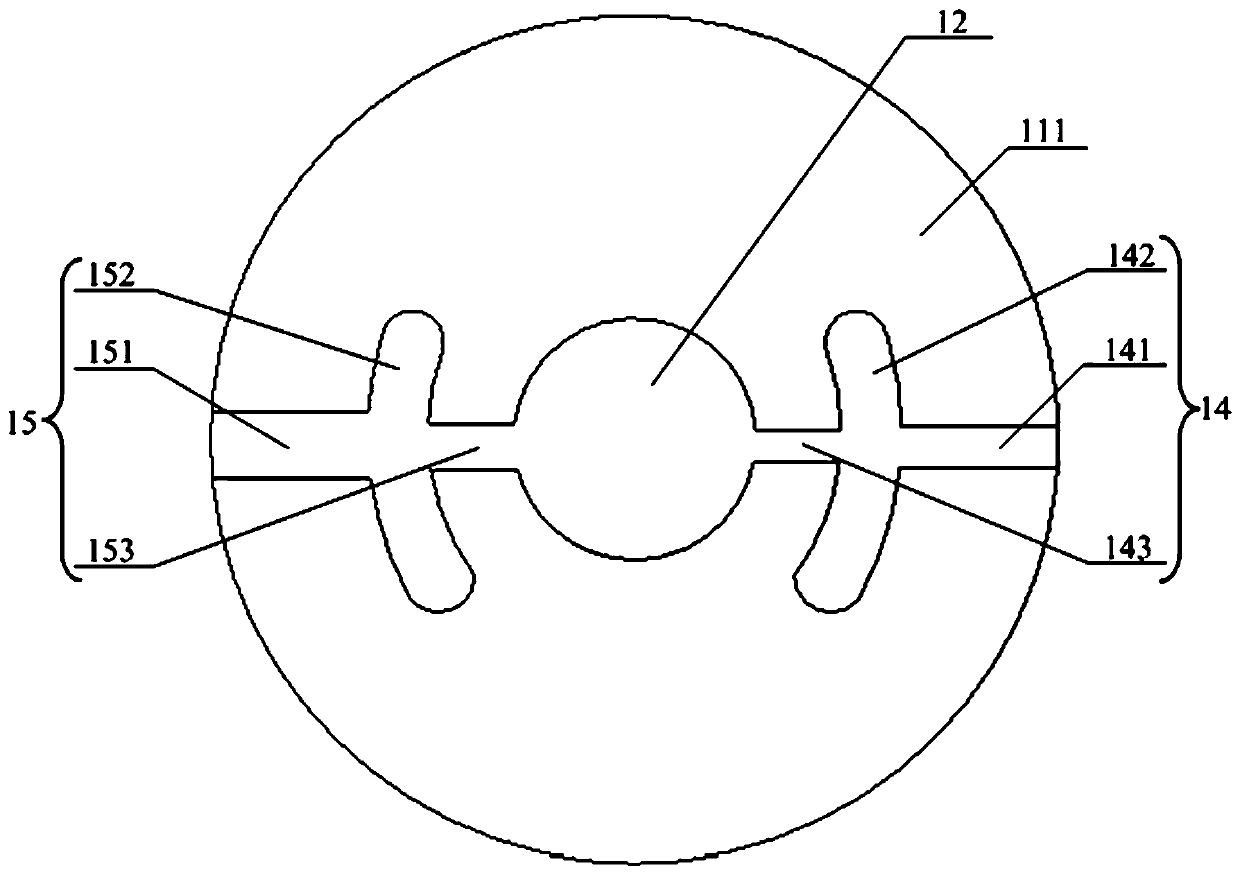

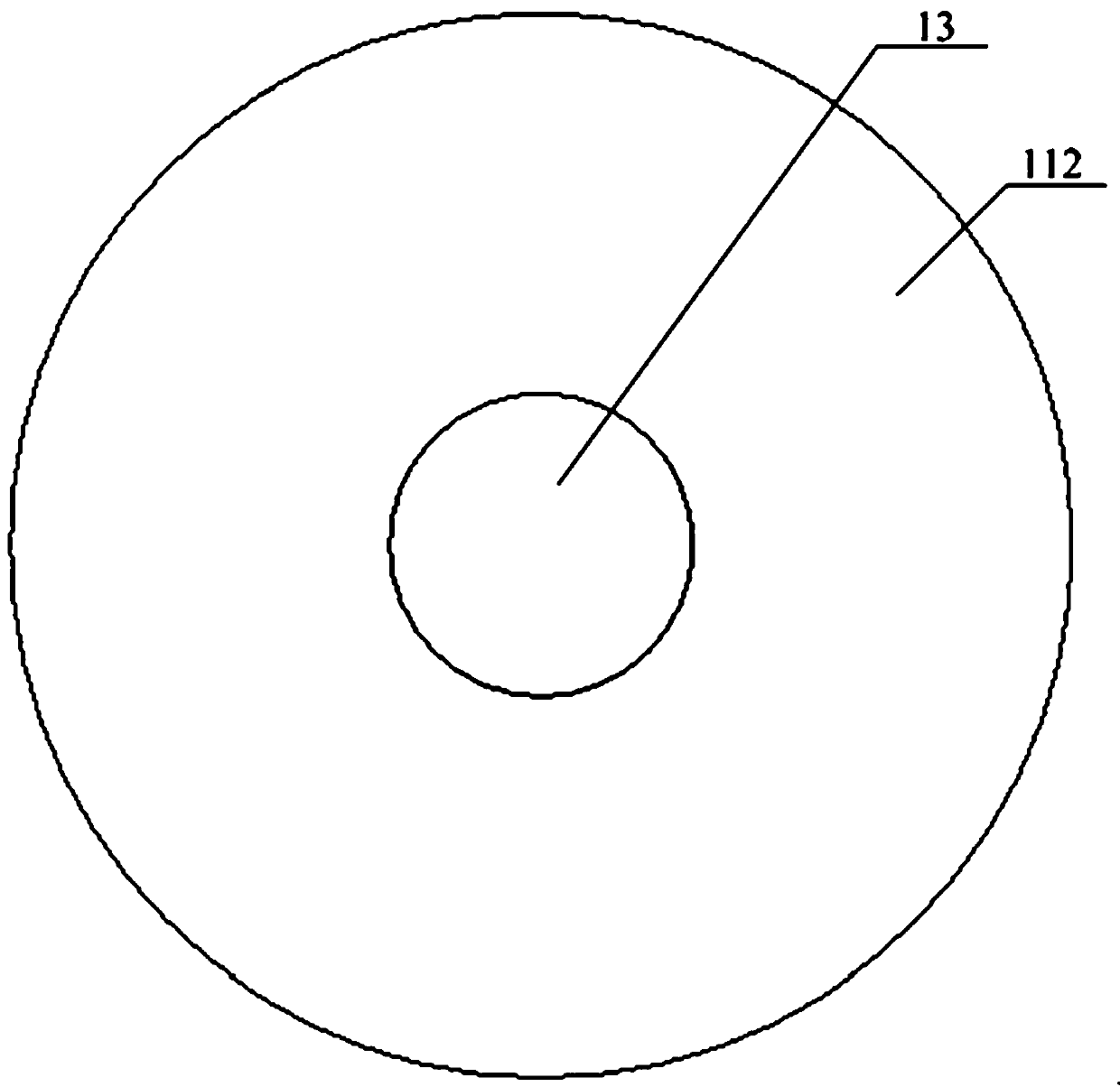

[0106] see figure 1 , the present invention provides a microfluidic chip 1, the microfluidic chip 1 includes: a frame structure 11; a first window 12, the first window 12 is embedded in the frame structure 11; A window 12 can comprise an infrared transparent window or an infrared reflective window; a second window 13, the second window 13 can be embedded in the frame structure 11, and the second window 13 and the There is a gap between the first windows 12 to form a sample chamber 16 between the second windows 13 and the first windows 12; the second windows 13 may include infrared transparent windows; Liquid inlet channel 14, the liquid inlet channel 14 is located in the frame structure 11, one end of the liquid inlet channel 14 communicates with the sample chamber 16, and the other end extends to the surface of the frame structure 11 The liquid outlet flow channel 15, the liquid outlet flow channel 15 is located in the frame structure 11, one end of the liquid outlet flow ch...

Embodiment 2

[0127] Please combine Figure 1 to Figure 3 refer to Figure 4 and Figure 5 , the present invention also provides a microfluidic system, the microfluidic system includes: the microfluidic chip 1 as described in the first embodiment, the specific structure of the microfluidic chip 1 please refer to the first embodiment, No longer repeat here; supply device 2, described supply device 2 is connected with described liquid inlet channel 14 and described liquid outlet channel 15, and described supply device 2 is used for providing in described sample chamber 16 Liquid to be detected (for example, water), sample suspension (for example, cell suspension) or carrier liquid, the carrier liquid provides a living environment or liquid environment for the sample to be detected located in the sample chamber; temperature control device 3, The temperature control device 3 is used to place the microfluidic chip 1 and heat the liquid to be tested, the sample suspension or the carrier liquid ...

example 1

[0143] In this example, as Figure 4 As shown, the supply device 2 includes an injection device 20 with injection function, the liquid inlet pipeline 21, the injection device 22 with extraction function and the liquid outlet pipeline 23; The device 20 includes a syringe pump or a syringe, and the liquid inlet pipeline 21 and the liquid outlet pipeline 23 are silicone pipelines; the microfluidic chip 1 is connected to the supply device 2 in the following manner: the microfluidic chip 1 The liquid inlet channel 141 in the liquid inlet channel 14 of the fluidic chip 1 is connected to the syringe in the syringe pump 20 with an injection function via a pipe joint and a silicone tube. The liquid outlet channel 151 of the liquid outlet channel 15 in the fluidic chip 1 is connected to the syringe in the syringe pump 22 via a pipe joint and a silicone pipeline; The microfluidic chip 1 is connected to the temperature control device 3 in the following manner: the microfluidic chip 1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com