Lithium-sulfur battery positive pole framework material and preparation method thereof, lithium-sulfur battery positive pole material and lithium-sulfur battery

A lithium-sulfur battery and skeleton material technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of volume effect, slow polysulfide reaction kinetics, active material sulfur loss, battery capacity attenuation, etc., and achieve the suppression of shuttling effect, increase conductivity, and increase specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a preparation method of the lithium-sulfur battery cathode framework material described in the above technical solution, comprising the following steps:

[0045] (1) Aluminum nitrate, cobalt nitrate, sulfanilic acid, alkali and water are mixed to obtain a mixed solution;

[0046] (2) The mixed solution obtained in step (1) is subjected to a hydrothermal reaction to obtain a layered double metal hydroxide;

[0047] (3) Calcining the layered double metal hydroxide obtained in step (2) in a protective atmosphere to obtain a carbonized material;

[0048] (4) soaking the carbonized material obtained in step (3) in an acidic solution to obtain a lithium-sulfur battery positive electrode framework material.

[0049] The invention mixes aluminum nitrate, cobalt nitrate, m-aminobenzenesulfonic acid, alkali and water to obtain a mixed solution.

[0050] In the present invention, the molar ratio of the aluminum nitrate, cobalt nitrate and m-aminobe...

Embodiment 1

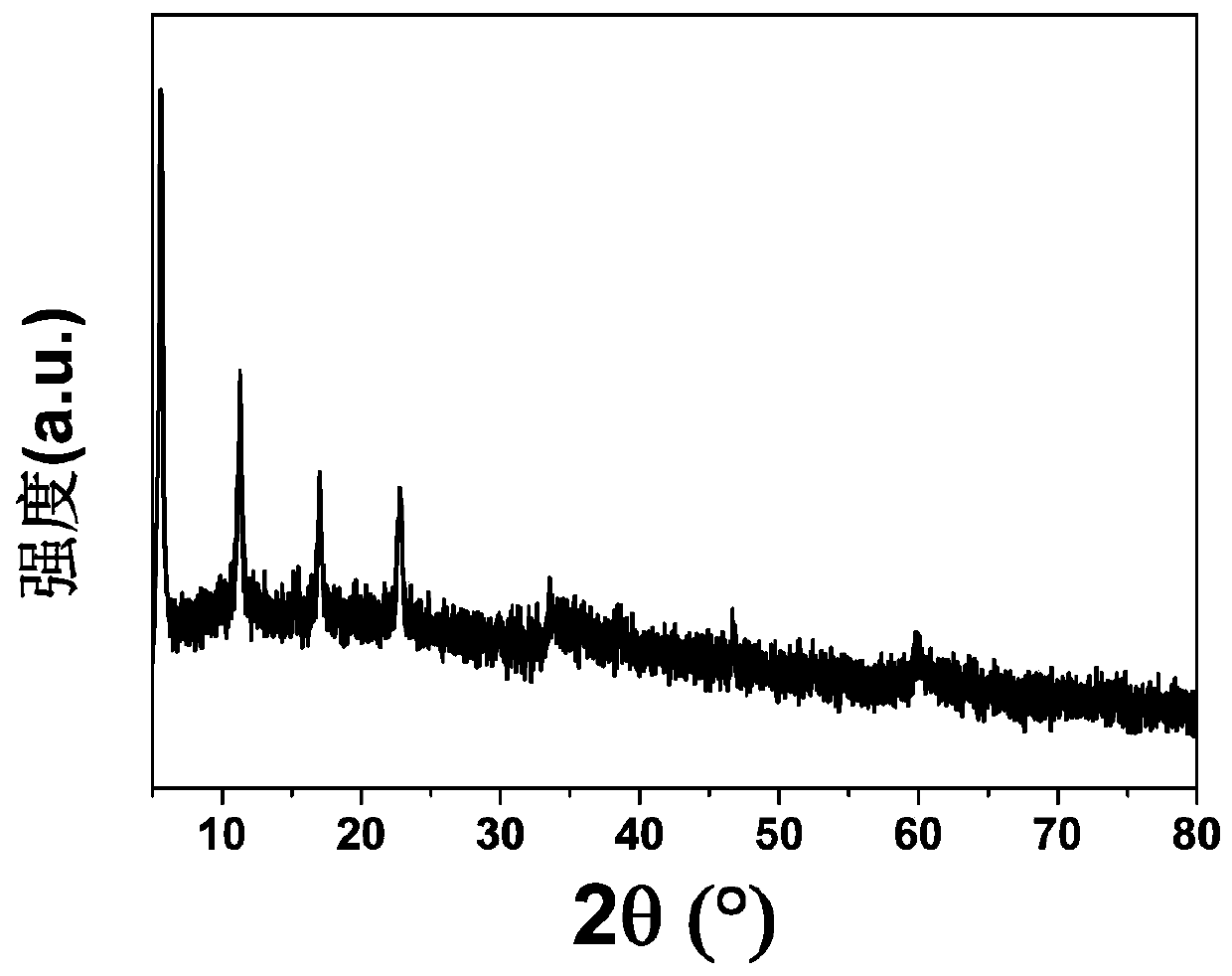

[0067] (1) 75g aluminum nitrate nonahydrate, 58g cobalt nitrate hexahydrate, 30g ammonium fluoride and 140g hexamethylenetetramine were dissolved in 2L deionized water, named solution A; in addition, 344g m-aminobenzenesulfonic acid was dissolved in 2L of sodium hydroxide solution with a concentration of 1mol / L, named solution B; slowly add solution B to solution A, then transfer the mixed solution into a 5L reaction kettle, and keep it at 100°C for 12h. After cooling to room temperature, the precipitate was fully washed with water and ethanol, and dried at 100°C for 20 hours to obtain a flower-like layered aluminum-cobalt hydroxide named CoAl-LDH.

[0068] (2) Transfer the prepared CoAl-LDH into a tube furnace, feed nitrogen, heat up at a rate of 5°C / min, carbonize at 700°C for 2 hours, and then cool to room temperature to obtain a flower-shaped carbonized material , named c-LDH.

[0069] (3) Soak the prepared c-LDH with 1.5 L of hydrochloric acid with a mass concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com