Heat-resistant magnetic domain refined-type oriented silicon steel and manufacturing method thereof

A technology of magnetic domain refinement and oriented silicon steel, which is used in the manufacture of inductors/transformers/magnets, manufacturing tools, magnetic objects, etc., which can solve the problem of the reduction of the lamination coefficient of silicon steel sheets, the difficulty in obtaining oriented silicon steel sheets, and the conduction between transformer sheets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-22 and comparative example 1-10

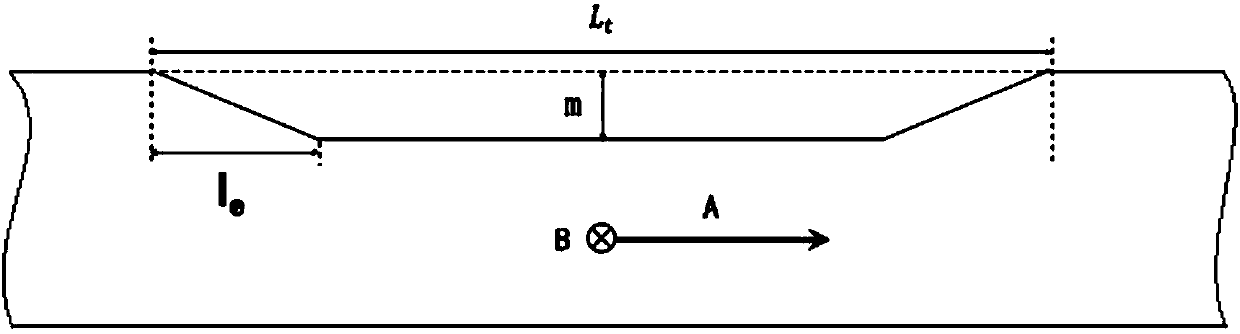

[0063] Table 1 lists the characteristic parameters of the grooves of the heat-resistant magnetic domain refinement grain-oriented silicon steel of Examples 1-22 and Comparative Examples 1-10.

[0064] Table 1.

[0065]

[0066]

[0067] in,

[0068] The heat-resistant magnetic domain refinement type grain-oriented silicon steel of Examples 1-22 and Comparative Examples 1-10 was prepared by the following steps:

[0069] (1) The oriented silicon steel is subjected to ironmaking, steelmaking, continuous casting, hot rolling, and then cold rolling to a final thickness of 0.23mm;

[0070] (2) After the decarburization annealing process at 850 ° C, the surface oxide layer is formed, and the MgO release agent is coated on the surface, and rolled into a steel coil;

[0071] (3) Keeping it under the condition of high temperature annealing at 1200°C for 20 hours, then coating the surface with an insulating coating and performing final annealing to form a oriented silicon steel...

Embodiment 23-37 and comparative example 11-15

[0089] Table 4 lists the characteristic parameters of the grooves of the heat-resistant magnetic domain refining grain-oriented silicon steel of Examples 23-37 and Comparative Examples 11-15.

[0090] Table 4.

[0091]

[0092]

[0093] in,

[0094] The heat-resistant magnetic domain refinement type grain-oriented silicon steel of Examples 23-37 and Comparative Examples 11-15 was prepared by the following steps:

[0095] (1) The oriented silicon steel is subjected to ironmaking, steelmaking and hot rolling processes, and then cold rolled to 0.26mm;

[0096] (2) Implement laser scoring on both sides of the cold-rolled sheet (the specific process parameters of the laser scoring are listed in Table 5);

[0097] (3) Decarburizing and annealing the scored cold-rolled sheet at 850°C to form a surface oxide layer, coat the surface with MgO release agent, and roll it into a steel coil;

[0098] (4) Keep it under the condition of high temperature annealing at 1200° C. for 20...

Embodiment 38-54 and comparative example 16-21

[0108] Table 7 lists the characteristic parameters of the grooves of the heat-resistant magnetic domain refinement grain-oriented silicon steel of Examples 38-54 and Comparative Examples 16-21.

[0109] Table 7.

[0110]

[0111] in,

[0112] The heat-resistant magnetic domain refinement grain-oriented silicon steels of Examples 38-54 and Comparative Examples 16-21 were prepared by the following steps:

[0113] (1) Go through iron-making, steel-making, and hot-rolling processes for oriented silicon steel, and then go through a cold rolling process to 0.226mm;

[0114] (2) After decarburization annealing, apply MgO release agent on the surface of the steel plate and dry it, and then roll it into a steel coil;

[0115] (3) Maintaining for 20 hours under high-temperature annealing conditions at 1200° C., cleaning off the unreacted residual MgO on the surface, and obtaining a cold-rolled sheet;

[0116] (4) Implement laser scoring on one side of the cold-rolled sheet, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com