Power transformer with magnetic core of silicon steel strip and its production method

A technology for power transformers and silicon steel strips, applied in transformer/inductor magnetic cores, transformer/inductor components, transformer/reactor installation/support/suspension, etc., can solve high cost, high-performance transformer production process complexity, etc. problems, to achieve the effect of eliminating internal stress, improving secondary recrystallization ability, and refining magnetic domains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

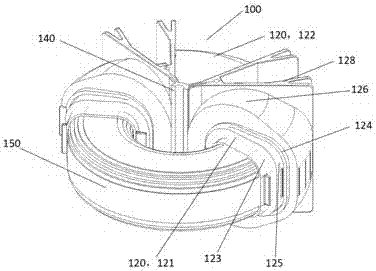

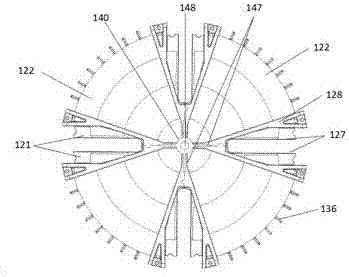

[0047] Such as Figures 1 to 11 In the preferred embodiment of the winding-magnetic core module 100 shown in the present invention, it includes at least two winding assemblies 120; each winding assembly 120 includes inner and outer windings 121, 122 nested together on a common axis; The inner and outer layer windings 121, 122 include inner and outer layer porcelain skeletons 123, 124, and inner and outer layer coils 125, 125 and outer layer coils 125 made of glass fiber insulated copper wire wound on the inner and outer layer porcelain skeletons 123, 124 respectively. 126; the cavities 131, 132 in the central part of the cross-section of the inner and outer windings 121, 122 are approximately rectangular, and are used to accommodate the silicon steel strips that are wound around and allow the two windings 121, 122 to overlap; the windings - Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com