Laser on-line high speed scratching device based on vibrating mirror array

A mirror array and high-speed technology, which is applied in the field of laser online high-speed scribing devices, can solve the problems of low efficiency, difficulty in meeting high production efficiency, and long-distance online production requirements, and achieve wide scanning format, fast scribing speed, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

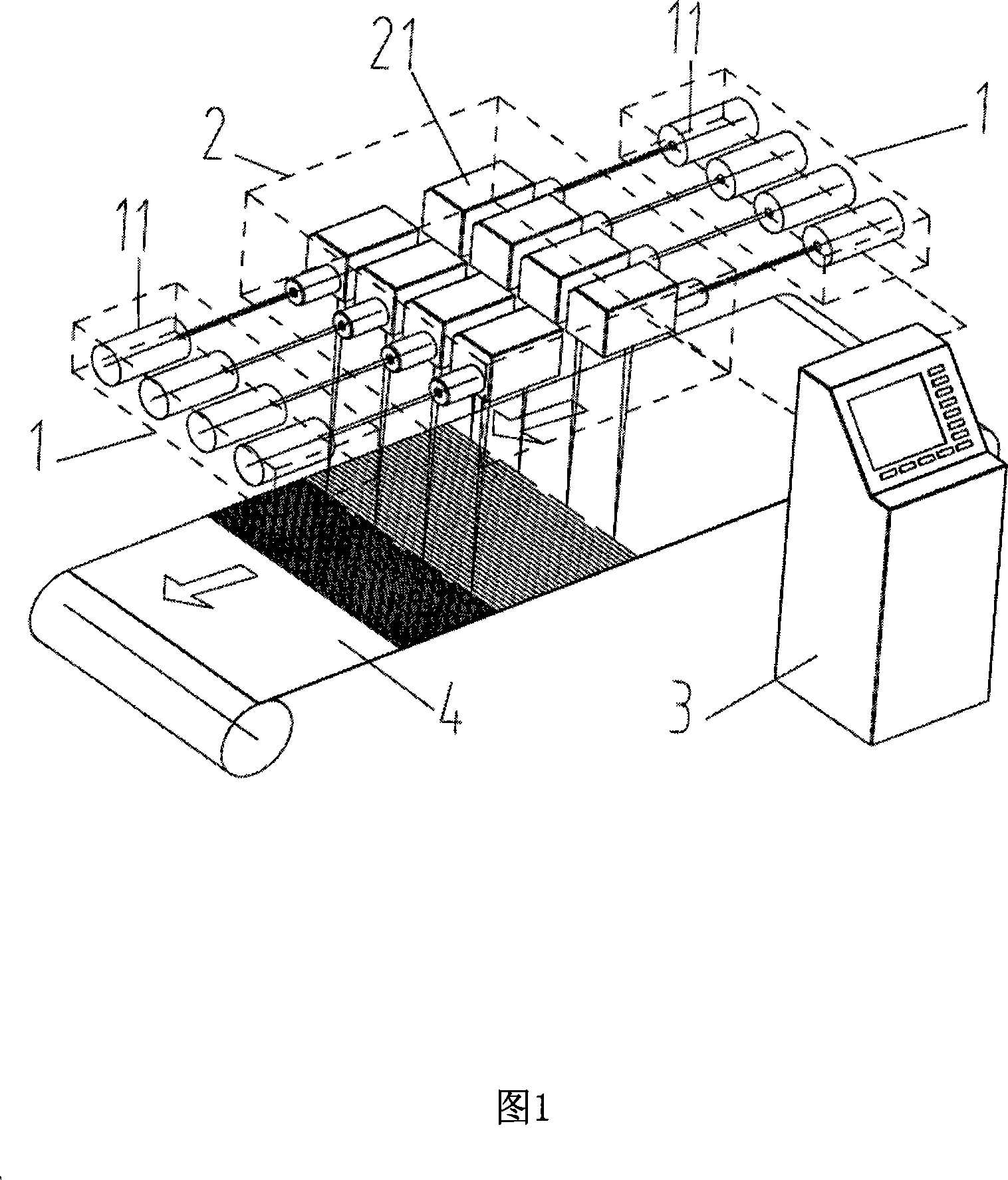

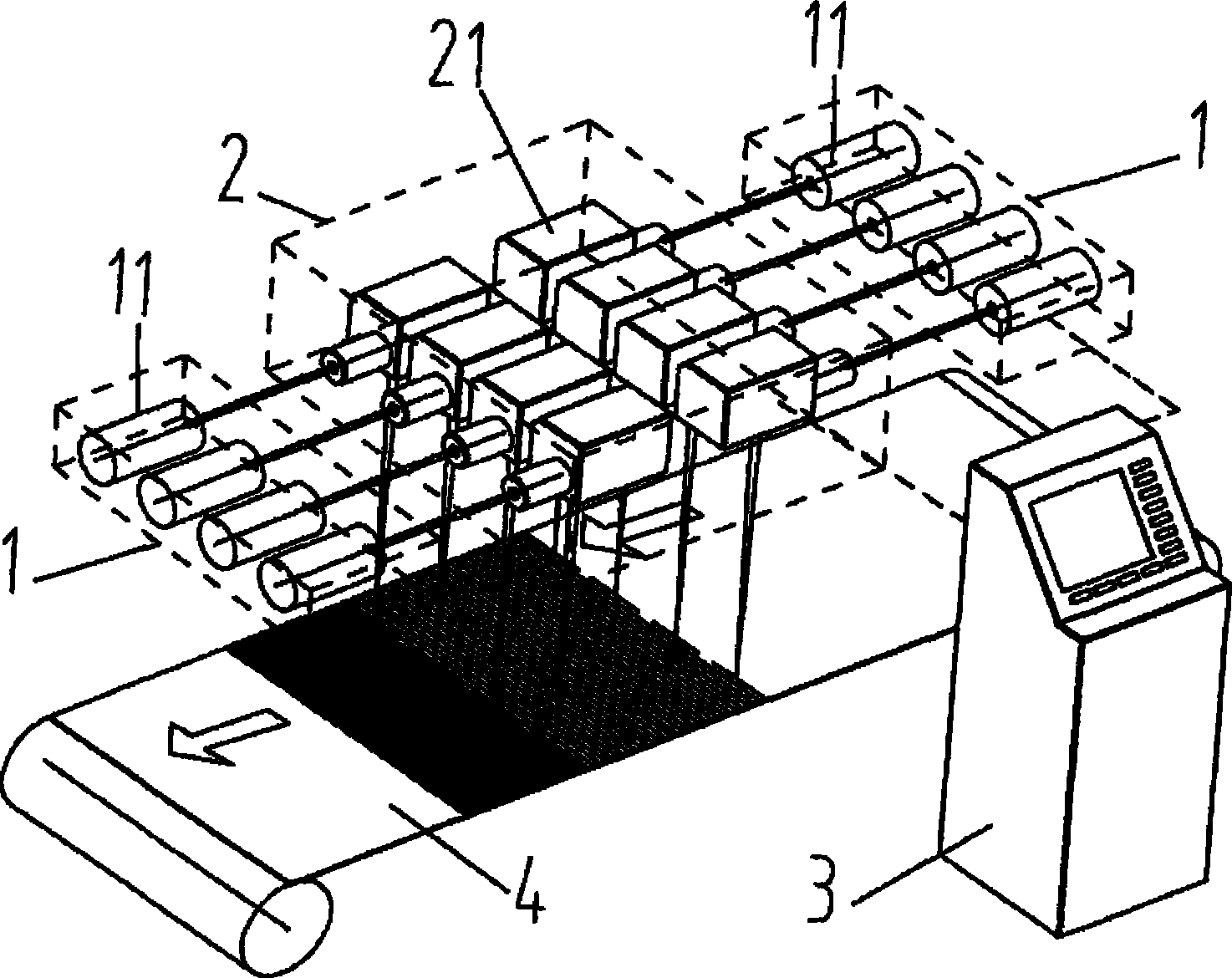

[0011] The present invention will be further described below in conjunction with accompanying drawing, see attached drawing figure 1 , a laser online high-speed marking device based on a galvanometer array, which includes a conveyor belt 4, a galvanometer array 2, a laser array 1, a control device 3 for controlling the galvanometer array 2 and the laser array 1, the galvanometer array 2 and The laser array 1 is located directly above the conveyor belt 4, and each laser 11 in the laser array 1 is set correspondingly to the galvanometer 21 in the galvanometer array 2, and the control device 3 for controlling the scanning track and speed of the galvanometer array 2 passes through cables respectively It is electrically connected with the vibrating mirror array 2 and the laser array 1. The vibrating mirror array 2 is composed of a plurality of transverse vibrating mirrors 21 moving in the transverse direction and a plurality of longitudinal vibrating mirrors 21 moving in the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com