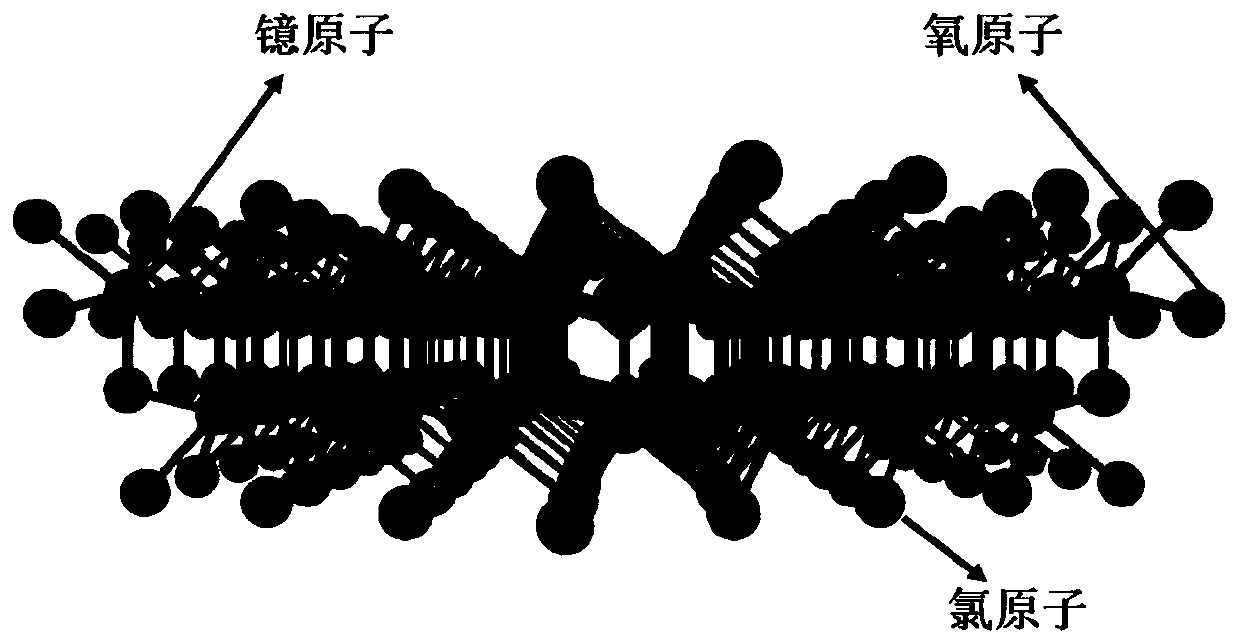

Ytterbium oxychloride nanosheet and preparation method and application thereof

A technology of ytterbium oxychloride and nanosheets is applied in the field of inorganic semiconductor materials, which can solve the problems of influence of application scope, long reaction time and high equipment requirements, and achieve the effects of convenient operation, fast reaction speed and stable chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

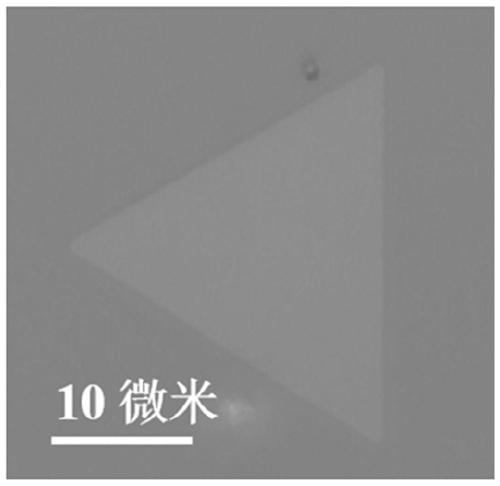

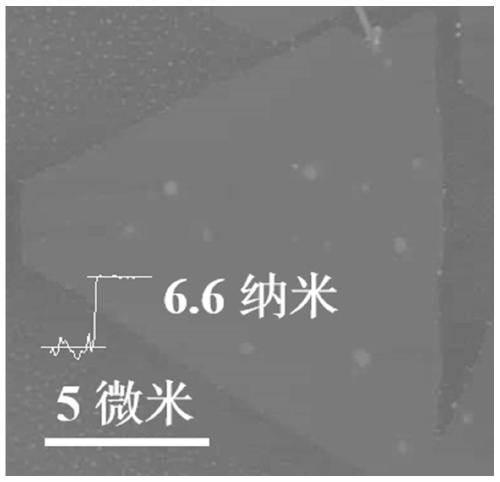

Embodiment 1

[0039] The present embodiment provides a kind of YbOCl nano sheet, and its preparation method specifically comprises the following steps:

[0040] (1) Add 0.5g Yb 2 o 3 , 0.5gYbCl 3 ·6H 2 O and 0.05g NaCl are mixed evenly, placed in a quartz boat, and the clean double-sided polished sapphire substrate is buckled on the quartz boat loaded with uniformly mixed powder;

[0041] (2) Place the quartz boat carrying the double-sided sapphire substrate in the middle of the quartz tube of the single-temperature zone tube furnace, and then repeatedly clean the quartz tube with argon, then raise the furnace temperature to 760 within 30 minutes. ℃, keep the flow rate of the carrier gas Ar at 120 sccm, grow for 30 minutes and then cool down to room temperature naturally to obtain YbOCl nanosheets grown on the sapphire substrate.

Embodiment 2

[0043] The present embodiment provides a kind of YbOCl nano sheet, and its preparation method specifically comprises the following steps:

[0044](1) Add 0.5g Yb 2 o 3 , 0.5gYbCl 3 ·6H 2 O and 0.1g NaCl are mixed evenly, placed in a quartz boat, and the clean double-sided polished sapphire substrate is buckled on the quartz boat loaded with uniformly mixed powder;

[0045] (2) Place the quartz boat carrying the double-sided sapphire substrate in the middle of the quartz tube of the single-temperature zone tube furnace, and then repeatedly clean the quartz tube of the single-temperature zone tube furnace with argon, and within 30 minutes Raise the furnace temperature to 780°C, keep the flow rate of the carrier gas (argon) at 150 sccm, grow for 30 minutes and then cool down to room temperature naturally to obtain YbOCl nanosheets grown on the sapphire substrate.

Embodiment 3

[0047] The present embodiment provides a kind of YbOCl nano sheet, and its preparation method specifically comprises the following steps:

[0048] (1) Add 0.45g Yb 2 o 3 , 0.5gYbCl 3 ·6H 2 O and 0.1g NaCl are mixed evenly, placed in a quartz boat, and the clean double-sided polished sapphire substrate is buckled on the quartz boat loaded with uniformly mixed powder;

[0049] (2) Place the quartz boat carrying the double-sided sapphire substrate in the middle of the quartz tube of the single-temperature zone tube furnace, and then repeatedly clean the quartz tube of the single-temperature zone tube furnace with argon, and within 30 minutes Raise the furnace temperature to 750°C, keep the flow rate of the carrier gas (argon) at 120 sccm, grow for 40 minutes and cool down to room temperature naturally to obtain YbOCl nanosheets grown on the sapphire substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com