TiCoMoNb basic shaft tile lubricating self-regulating composite material and preparation method thereof

A composite material and self-regulating technology, used in additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems of reduced friction and wear performance, restricting the rapid development of titanium-based bearing shell structural parts, etc. The effect of remarkable enrichment behavior and excellent friction and wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

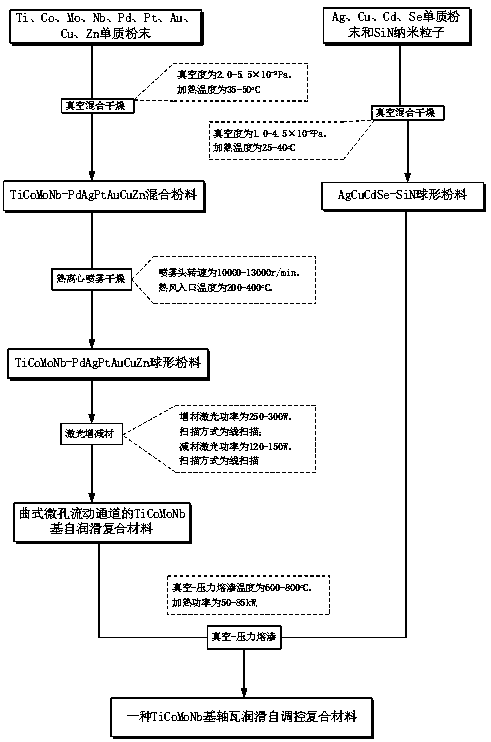

Method used

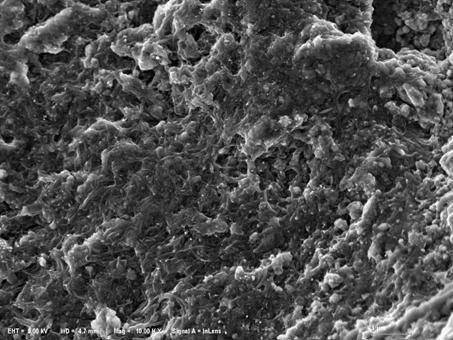

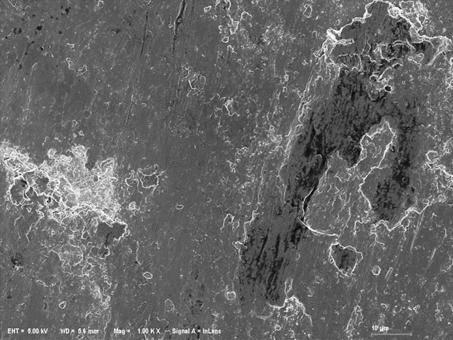

Image

Examples

Embodiment 1

[0029] A TiCoMoNb-based bearing bush lubrication self-regulating composite material with PdAgPtAuCuZn as the lubricating phase and AgCuCdSe-SiN as the lubrication regulator is prepared. It is characterized in that the TiCoMoNb-based bearing bush lubricating self-regulating composite material is prepared by using the laser addition and subtraction material manufacturing technology and the vacuum pressure infiltration process. The atomic ratio (at%) of the matrix material TiCoMoNb is 20:16:12:3, and the atomic ratio (at%) of the lubricating phase PdAgPtAuCuZn is 35:30:10:10:1:1. The mass ratio (wt%) of regulator AgCuCdSe to SiN is 1:1, the atomic ratio (at%) of Ag, Cu, Cd, Se is 3:2:3:5, and the atomic ratio (at%) of SiN nanoparticles is 3: 5. The mass ratio of the solid lubricating phase PdAgPtAuCuZn to the matrix material TiCoMoNb is 1:10, and the mass ratio of the lubrication regulator AgCuCdSe-SiN to the matrix material TiCoMoNb is 1:15. According to the above ratio, Ti, C...

Embodiment 2

[0039] A TiCoMoNb-based bearing bush lubrication self-regulating composite material with PdAgPtAuCuZn as the lubricating phase and AgCuCdSe-SiN as the lubrication regulator is prepared. It is characterized in that the TiCoMoNb-based bearing bush lubricating self-regulating composite material is prepared by using the laser addition and subtraction material manufacturing technology and the vacuum pressure infiltration process. The atomic ratio (at%) of the matrix material TiCoMoNb is 20:16:12:3.5, and the atomic ratio (at%) of the lubricating phase PdAgPtAuCuZn is 35:30:10:10:1:0.7. The mass ratio (wt%) of regulator AgCuCdSe to SiN is 3:1, the atomic ratio (at%) of Ag, Cu, Cd, Se is 4:2:3:6, and the atomic ratio (at%) of SiN nanoparticles is 3: 7. The mass ratio of the lubricating phase PdAgPtAuCuZn to the matrix material TiCoMoNb is 1:3, and the mass ratio of the lubrication regulator AgCuCdSe-SiN to the matrix material TiCoMoNb is 1:7. According to the above ratio, Ti, Co, M...

Embodiment 3

[0049] A TiCoMoNb-based bearing bush lubrication self-regulating composite material with PdAgPtAuCuZn as the lubricating phase and AgCuCdSe-SiN as the lubrication regulator is prepared. It is characterized in that the TiCoMoNb-based bearing bush lubricating self-regulating composite material is prepared by using the laser addition and subtraction material manufacturing technology and the vacuum pressure infiltration process. The atomic ratio (at%) of the matrix material TiCoMoNb is 20:16:12:5, and the atomic ratio (at%) of the lubricating phase PdAgPtAuCuZn is 35:30:10:10:1:0.4. The mass ratio (wt%) of regulator AgCuCdSe to SiN is 7:1, the atomic ratio (at%) of Ag, Cu, Cd, Se is 5:2:3:7, and the atomic ratio (at%) of SiN nanoparticles is 1: 3. The mass ratio of the lubricating phase PdAgPtAuCuZn to the matrix material TiCoMoNb is 1:5, and the mass ratio of the lubrication regulator AgCuCdSe-SiN to the matrix material TiCoMoNb is 1:10. Vacuum mixing and drying Ti, Co, Mo, Nb,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com