High-strength and ductility aluminum-silicon-based composite welding wire and preparation method thereof

A composite material and welding wire technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of inability to strengthen elements of aluminum-silicon alloy and easily cause pores, and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

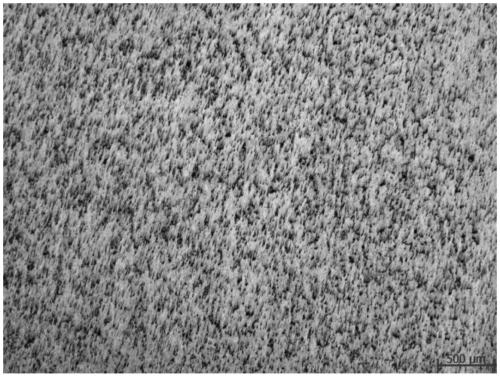

Embodiment 1

[0039] Put 299g of pure aluminum and 680g of Al-Si master alloy in a crucible, wait for it to melt, then add JZF-03 type covering agent to cover it evenly, then raise the temperature to 700°C for melting; put the uniformly mixed KBF 4 、K 2 TiF 6 After the powder is dried, it is added to the melt and stirred. After the reaction is completed, the masterbatch is obtained after the slag is removed; after the masterbatch is melted in a crucible, 11g of Mg pellets are added, and JZJ type harmless aluminum alloy refining agent is added for degassing and refining. The temperature is 650~750°C, put the melt at rest for 45 minutes to obtain an ingot; perform homogenization annealing on the ingot, that is, keep it at a temperature of 505°C for 28 hours. The fully homogenized aluminum-based composite billet is extruded into an aluminum alloy wire billet with a diameter of 20mm by an extrusion machine, the extrusion ratio is controlled at 8, and the extrusion speed is 1.0-2.0m / min; the dr...

Embodiment 2

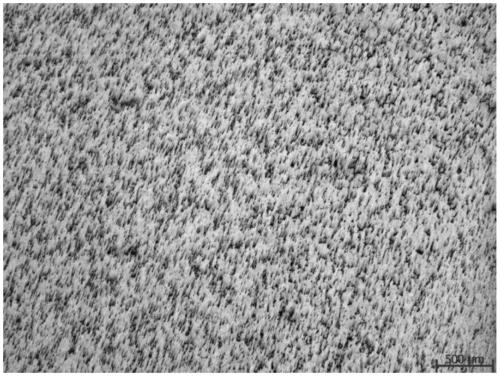

[0045] Put 330g of pure aluminum and 654g of Al-Si master alloy in a crucible, wait for it to melt, add JZF-03 type covering agent to cover evenly, then raise the temperature to 750°C for melting; put the uniformly mixed KBF 4 、K 2 TiF 6 After the powder is dried, it is added to the melt and stirred. After the reaction is completed, the masterbatch is obtained after the slag is removed; the masterbatch is put into a crucible and melted, and then 7g of Mg particles are added in sequence, and JZJ type harmless aluminum alloy refining agent is added for degassing and refining. The temperature is 650-750°C, and the melt is obtained after standing for 50 minutes; the ingot is subjected to homogenization annealing, that is, it is kept at a temperature of 510°C for 30 hours. The fully homogenized aluminum-based composite billet is extruded into an aluminum alloy wire billet with a diameter of 20mm by an extrusion machine, the extrusion ratio is controlled at 7.5, and the extrusion s...

Embodiment 3

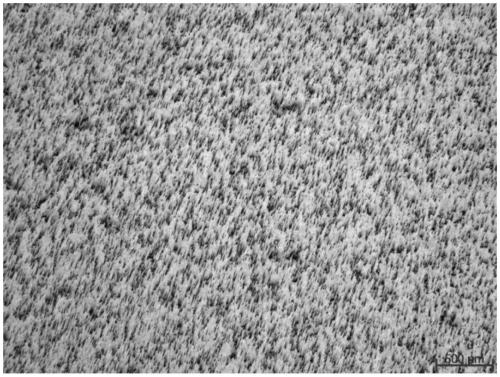

[0051] Put 293.8g of pure aluminum and 686g of Al-Si master alloy in a crucible, wait for it to melt, add JZF-03 type covering agent to cover evenly, then raise the temperature to 800°C for melting; put the uniformly mixed KBF 4 、K 2 TiF 6 After the powder is dried, it is added to the melt and stirred. After the reaction is completed, the masterbatch is obtained after the slag is removed; the masterbatch is put into the crucible to melt, and after adding 4.5g of Mg pellets in turn, add JZJ type harmless aluminum alloy refining agent for degassing and refining. The temperature is 650-750°C, and the melt is obtained after standing for 60 minutes; the ingot is homogenized and annealed, that is, kept at a temperature of 500°C for 24 hours. The fully homogenized aluminum-based composite billet is extruded into an aluminum alloy wire billet with a diameter of 20mm by an extrusion machine, the extrusion ratio is controlled at 7, and the extrusion speed is 1.0-2.0m / min; the drawing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com