Light prefabricated type concrete plate column foundation and construction method thereof

A prefabricated concrete and prefabricated assembly technology, applied in the field of engineering, can solve the problems of increased difficulty in transportation of machinery and equipment required for hoisting, difficulty in mass production of prefabricated foundations, and easy corrosion and damage of steel components, so as to improve the efficiency of component transportation and hoisting, and enhance The ability to resist adverse environmental influences and the effect of reducing the difficulty of construction and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

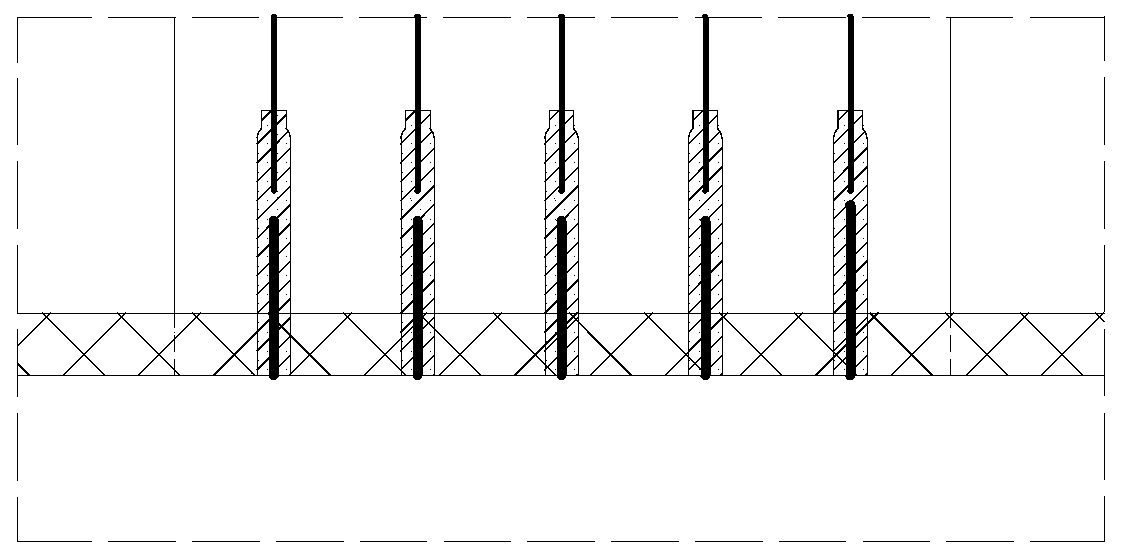

[0072] The invention provides a lightweight prefabricated concrete slab-column foundation, comprising prefabricated lightweight aggregate concrete foundation columns and spliceable bottom plates, the bottom plates are connected and assembled through prestressed tendons, and the bottom plate as a whole is connected to the foundation column through connecting sleeve grouting.

[0073] A lightweight aggregate concrete with a prefabricated prefabricated foundation, with a strength not lower than LC30, an impermeability grade not lower than P4, and a density range of 1500kg / m 3 ~1950kg / m 3 . Taking LC35 grade lightweight aggregate concrete as an example, its mix ratio is (unit: kg / m 3 ):

[0074] Cement: fine aggregate: light coarse aggregate: fly ash: silica fume: superplasticizer: water = 298:662:645:187:50:4.28:165.

[0075] The cement mentioned above uses P.O 42.5R ordinary Portland cement with stable quality and good performance. It needs to be tested for compatibility with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com