Wafer processing method

A processing method and wafer technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as transfer between processes that cannot be used, pick-up and lamination damage, large warping deformation, etc., to achieve Reduce the risk of fragmentation, improve stress distribution, and reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

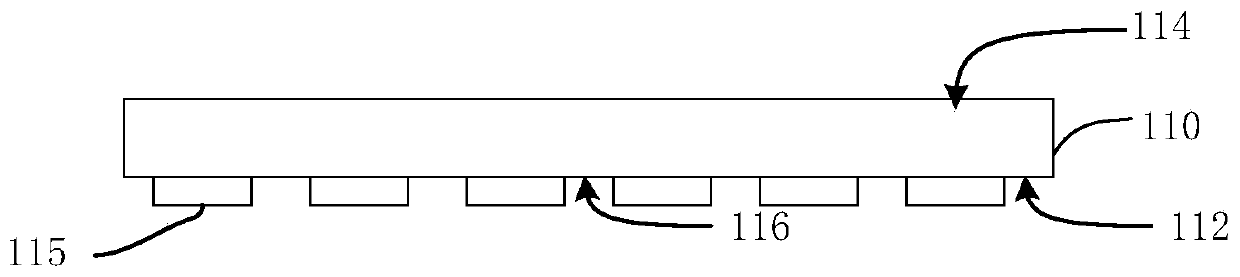

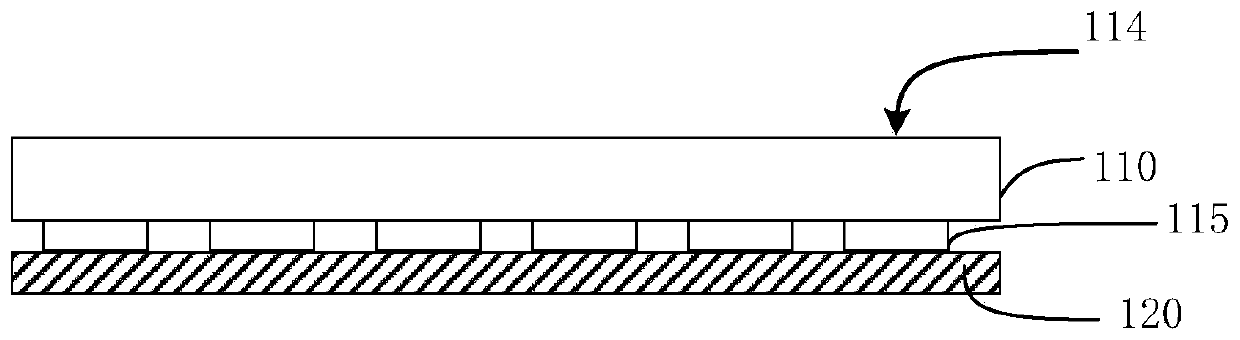

[0055] (1) Thinning the wafer by grinding the back side of the original wafer: adopting a fully automatic grinding and polishing machine that is DISCO DGP8761 with the ability to process wafers of 12 inches and below; The 12-inch raw wafer 110 is ground and polished to obtain an ultra-thin wafer 111 with a thickness of 15 μm.

[0056] (2) The support film 130 is pasted on the back surface 114 of the ultra-thin wafer 111 after grinding by using the dicing iron ring 140 . The support film 130 includes an organic film layer 132 made of polyimide, an adhesive layer 134 and a release film layer 136. The release film layer 136 is torn off during the stretching process. After the stretching is completed, the ultra-thin wafer The back surface 114 of the circle 111 is pasted with the adhesive layer 134 of the supporting film 130 and the organic film layer 132 . The material of the organic film layer 132 is polyimide.

[0057] (3) Cut off the redundant supporting film 130 along the ce...

Embodiment 2

[0063] (1) Thinning the wafer by grinding the back side of the original wafer: using a fully automatic grinding and polishing machine that is ACCRETECH PG3000RMX with the ability to process wafers of 12 inches and below, the graphic surface 112 is pasted with a protective film 120 The 8-inch raw wafer 110 is ground and polished to obtain an ultra-thin wafer 111 with a thickness of 20 μm.

[0064] (2) The support film 130 is pasted on the back surface 114 of the ultra-thin wafer 111 after grinding by using the dicing iron ring 140 . The support film 130 includes an organic film layer 132 made of polyimide, an adhesive layer 134 and a release film layer 136. The release film layer 136 is torn off during the stretching process. After the stretching is completed, the ultra-thin wafer The back surface 114 of the circle 111 is pasted with the adhesive layer 134 of the supporting film 130 and the organic film layer 132 . The material of the organic film layer 132 is polyimide.

[0...

Embodiment 3

[0071] (1) Thinning the wafer by grinding the back side of the original wafer: adopting a fully automatic grinding and polishing machine that is DISCO DGP8761 with the ability to process wafers of 12 inches and below; The 8-inch raw wafer 110 is ground and polished to obtain an ultra-thin wafer 111 with a thickness of 35 μm.

[0072] (2) The support film 130 is pasted on the back surface 114 of the ultra-thin wafer 111 after grinding by using the dicing iron ring 140 . The support film 130 includes an organic film layer 132 made of polyimide, an adhesive layer 134 and a release film layer 136. The release film layer 136 is torn off during the stretching process. After the stretching is completed, the ultra-thin wafer The back surface 114 of the circle 111 is pasted with the adhesive layer 134 of the supporting film 130 and the organic film layer 132 . The material of the organic film layer 132 is polyimide.

[0073] (3) Cut off the redundant supporting film 130 along the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com