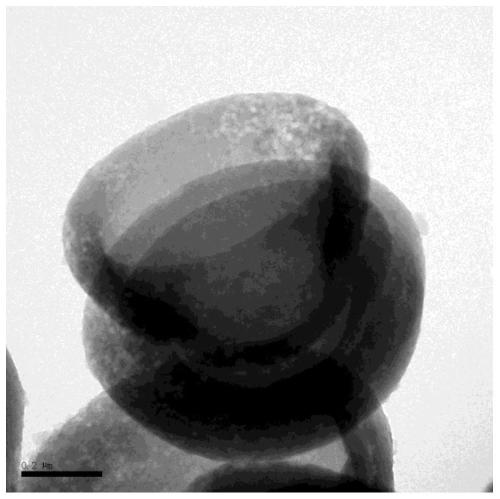

Nitrogen-oxygen double-doped porous hollow bowl-shaped carbon material and preparation method thereof

A double doping and hollow bowl technology, which is applied in the preparation/purification of carbon, electrical components, battery electrodes, etc., can solve the problems of low volumetric energy density of batteries and low tap density of powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A mixture containing 3 g of fructose and xylose (1:1) was added to 25 ml of deionized water, 9 ml of sodium oleate solution (10 mmol / L) and 9 ml of P123 solution (1 mmol / L) and stirred until Mix well, put the mixed transparent liquid into an 80ml polytetrafluoroethylene-lined stainless steel water heating tank, tighten the lid, put the water heating tank in an oven at 160°C, keep it warm for 15 hours, then take out the water heating tank Oven, placed in the air to cool to room temperature, then open the water-heated jar, pour out the mixture inside, centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, and then repeatedly wash with water and ethanol to obtain a hollow carbon bowl. Disperse 1 gram of hollow bowl-shaped carbon in 20 milliliters of potassium hydroxide solution (1mol / L), and ultrasonically mix, stir for 12 hours, centrifuge in a centrifuge at 8000 rpm, and then wash repeatedly with water and ethanol, The precipitate was obtained and dried at 70°C ...

Embodiment 2

[0024] Will contain the juice of three kinds of fruits apple, grape, sugar cane of 3 grams to add 20 milliliters of deionized aqueous solution, the sodium stearate solution (10mmol / L) of 8 milliliters and the F127 solution (1mmol / L) of 8 milliliters mix, and stir until Mix evenly, put the mixed transparent liquid into a 50ml polytetrafluoroethylene-lined stainless steel water heating tank, tighten the lid, put the water heating tank in an oven at 150°C, keep it warm for 20 hours, then take it out Oven, placed in the air to cool to room temperature, then open the water-heated jar, pour out the mixture inside, centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, and then repeatedly wash with water and ethanol to obtain a hollow carbon bowl. Disperse 2 grams of hollow bowl-shaped carbon in 20 milliliters of sodium hydroxide solution (2 mol / L), and ultrasonically mix, stir for 8 hours, centrifuge in a centrifuge at 8000 rpm, then wash repeatedly with water and ethanol, ...

Embodiment 3

[0026] Add 40 milliliters of deionized aqueous solution containing 3 grams of potato juice, 10 milliliters of N-oleoyl N-methyl taurine sodium solution (10mmol / L) and 10 milliliters of P123 solution (1mmol / L) mix, and stir until Mix evenly, put the mixed transparent liquid into a 100ml polytetrafluoroethylene-lined stainless steel water heating tank, tighten the lid, put the water heating tank in an oven at 170°C, keep it warm for 8 hours, then take out the water heating tank Oven, placed in the air to cool to room temperature, then open the water-heated jar, pour out the mixture inside, centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, and then repeatedly wash with water and ethanol to obtain a hollow carbon bowl. Disperse 1 gram of hollow bowl-shaped carbon in 20 milliliters of zinc chloride solution (1mol / L), and ultrasonically mix, stir for 6 hours, centrifuge in a centrifuge at 8000 rpm, then wash repeatedly with water and ethanol, The precipitate was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com