Preparation method and applications of iron-carbon micro-electrolysis material for maintaining long-term catalytic activity of Fenton system

A micro-electrolysis and graphitized carbon technology, applied in the field of highly toxic pollutant treatment, can solve the problems of shortening the service life of iron-carbon fillers, aggravating iron corrosion and loss, and increasing the operating cost of enterprises, achieving high load capacity and high utilization rate. , the effect of increasing the timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 : The preparation method of highly dispersed core-shell type Fe-C micro-electrolytic material of the present invention

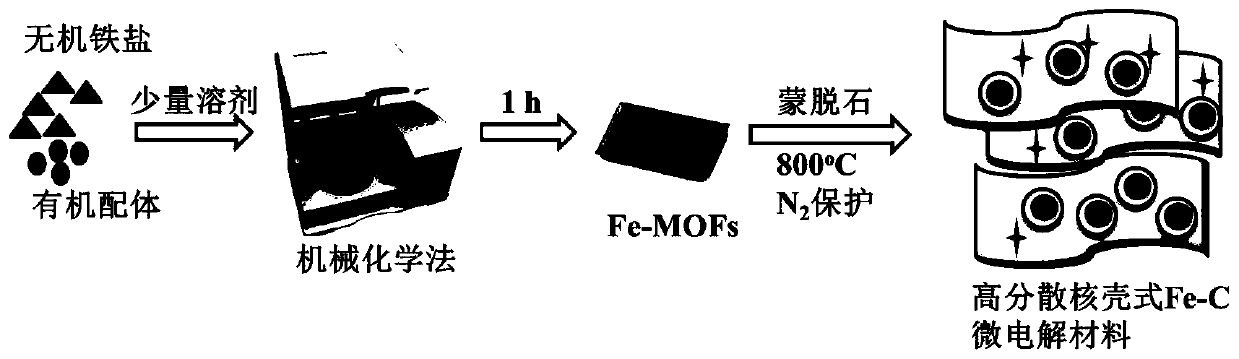

[0046] The synthesizing schematic diagram of highly dispersed core-shell type Fe-C micro-electrolytic material provided by the present invention is as follows figure 1 Shown, its specific preparation method is:

[0047] First, weigh a certain amount of FeCl 3 Add terephthalic acid and terephthalic acid into a zirconia grinding tank, then add a certain volume of tetramethylammonium hydroxide solution and 3-4 zirconia grinding balls, and grind for 0.5-2h at a speed of 300 rpm to obtain Fe-MOFs material: The prepared Fe-MOFs and montmorillonite are fully mixed, and heated at a high temperature of 800°C for 2 hours under the protection of nitrogen to obtain a highly dispersed core-shell Fe-C micro-electrolytic material.

Embodiment 2

[0048] Example 2 : Structural characterization of highly dispersed core-shell Fe-C microelectrolytic materials of the present invention

[0049]This embodiment is the structural characterization of the highly dispersed core-shell Fe-C micro-electrolytic material, specifically as follows:

[0050] 1.TEM

[0051] The particle size and morphology of highly dispersed core-shell Fe-C microelectrolytic materials were analyzed by transmission electron microscope H7500 (Hitachi, Japan).

[0052] from figure 2 It can be seen that the diameter of the zero-valent iron inner core of Fe-C nanoparticles is 15-30 nm, and the thickness of the carbon shell is about 5 nm. The core-shell Fe-C is embedded in a large amount of graphitized carbon, which increases the stability of the zero-valent iron in the core. The core-shell Fe-C nanoparticles are uniformly dispersed between the lamellar structures and the inner and outer surfaces of the montmorillonite with a layered structure.

[0053] ...

Embodiment 3

[0062] Example 3 : Catalytic performance test of highly dispersed core-shell type Fe-C micro-electrolytic material of the present invention

[0063] In this example, phenol and methyl orange were selected as representatives, and the catalytic performance of the highly dispersed core-shell Fe-C micro-electrolytic material was tested.

[0064] The operation steps of the test are as follows: configure 100 mg / L of phenol and 50 mg / L of methyl orange standard 50 mL, place it in a 100 mL polyethylene plastic vial, add 25 mg of highly dispersed core-shell Fe-C micro-electrolytic material, and make the catalyst The concentration is 0.5g / L, then add a certain concentration of H 2 o 2 . Shake in a shaker, take 0.5mL samples every once in a while, add 0.5mL ethanol, take the supernatant after centrifugation, and test phenol, methyl orange, TOC and Fe respectively. 2+ and H 2 o 2 determination. Phenol was measured by HPLC-UV, TOC was detected by TOC / TN analyzer, methyl orange, Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com