Preparation method of windproof warm camel hair composite flake

A technology of camel hair and wadding, which is applied in the field of windproof and warm-keeping camel hair composite wadding, which can solve problems affecting the air permeability and hygroscopicity of textiles, spinning difficulties, and emissivity not meeting the requirements, etc., and achieve excellent moisture absorption and moisture conduction performance, reduce Cold stress process, strong windproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

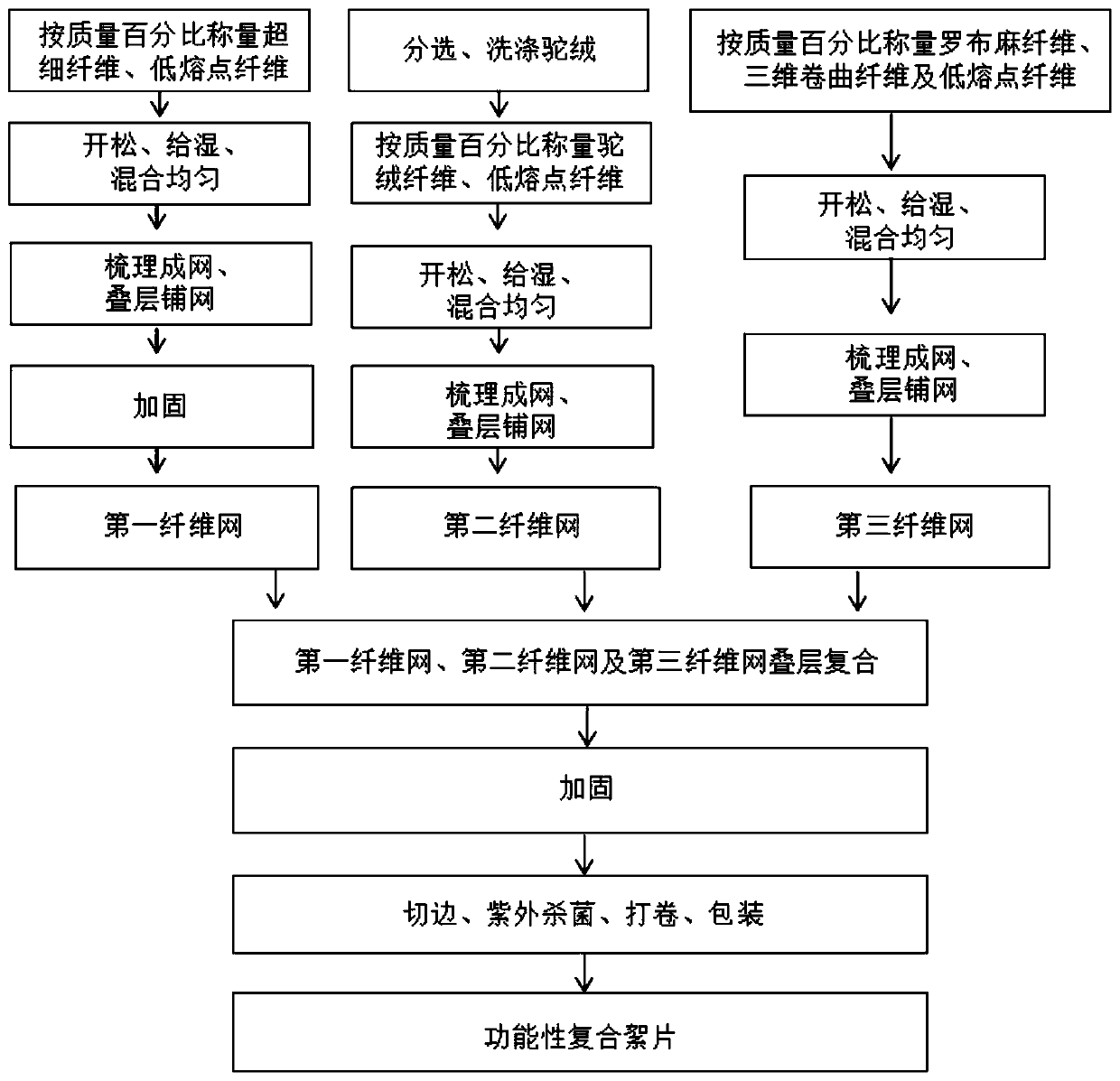

[0047] The preparation method of windproof and warm camel hair composite wadding, such as figure 1 As shown, the specific steps are:

[0048] (1) Preparation of the first fiber web layer

[0049] The fiber raw material of the first fiber web is mainly composed of superfine fibers with a mass percentage of 60% and ES hot-melt fibers with a mass percentage of 40%. The fineness of the superfine fibers is 0.8D, and the average length is 38mm. The fineness is 1.3D, and the average length is 51mm. The superfine fiber and ES hot-melt fiber are respectively opened, wetted, and mixed. Using simultaneous heating and pressurization, the heating temperature is 128°C, and the pressurization pressure is 1.2×10 5 Pa, the heating time is 2min, and the surface density of the first fiber web is controlled at 30g / m 2 ;

[0050] (2) Preparation of the second fiber web layer

[0051]The fiber raw material in the second fiber web is mainly composed of camel hair with a mass percentage of 80% a...

Embodiment 2

[0064] The preparation method of windproof and warm camel hair composite wadding, the specific steps are:

[0065] (1) Preparation of the first fiber web layer

[0066] The fiber raw material of the first fiber web is mainly composed of superfine fibers with a mass percentage of 60% and ES hot-melt fibers with a mass percentage of 40%. The fineness of the superfine fibers is 1.2D, and the average length is 51mm. The fineness is 1.3D, and the average length is 38mm. The superfine fiber and ES hot-melt fiber are respectively opened, wetted, and mixed. Using simultaneous heating and pressurization, the heating temperature is 132°C, and the pressurization pressure is 1.4×10 5 Pa, the heating time is 3min, and the surface density of the first fiber web is controlled at 50g / m 2 ;

[0067] (2) Preparation of the second fiber web layer

[0068] The fiber raw material in the second fiber web is mainly composed of camel hair with a mass percentage of 80% and ES hot-melt fibers with ...

Embodiment 3

[0083] The preparation method of windproof and warm camel hair composite wadding is basically the same as in Example 2, except that the fiber raw material content of the first fiber web is the first fiber web fiber raw material in Example 3. The percentage is 30% ES hot-melt fiber composition.

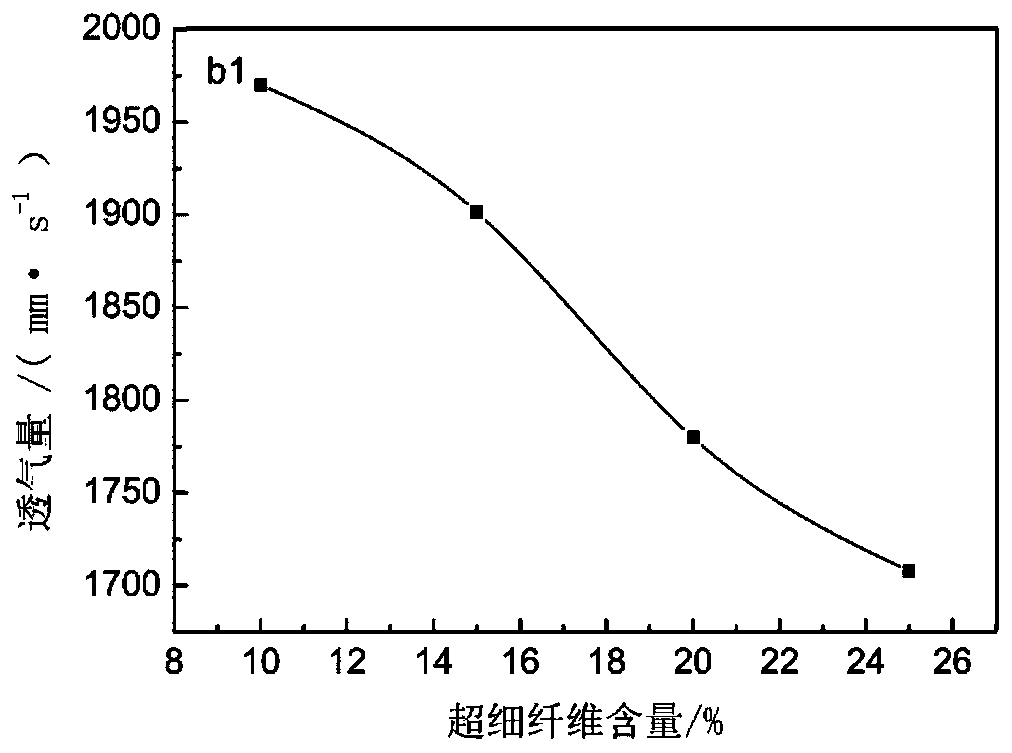

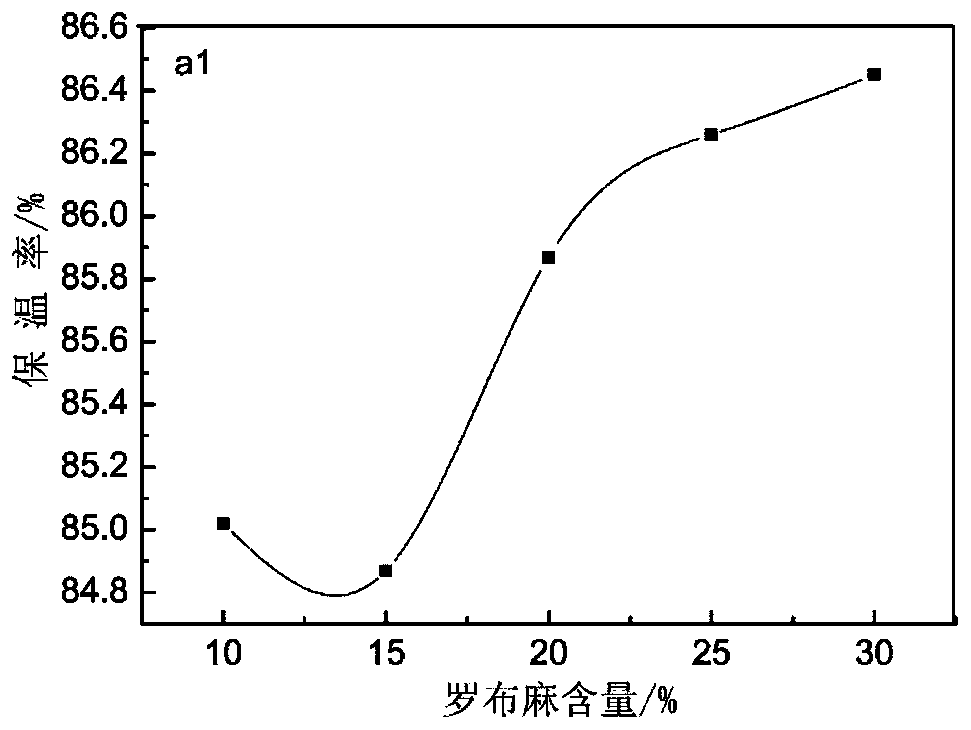

[0084]The finally prepared windproof and warm camel hair composite wadding has a composite layer structure, including the first fiber web layer, the second fiber web layer and the third fiber web layer which are successively adjacent and connected by low-melting fiber bonding, and the thermal insulation rate is 86.70%, the Cro value is 3.576°C·m 2 ·W -1 , the compression ratio is 70.87%, and the bulkiness is 53.42cm 3 g -1 , the air permeability is 1890mm·s -1 , the antibacterial rate is 80.5%, the one-way transmission index is 163, the UVA transmittance is 1.79%, the UVB transmittance is 1.56%, the UPF is 63.18, the electrostatic voltage is 1790V, and the air permeability is 1900m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com