Method for preparing antibacterial high-temperature-resistant plastic granules

A technology of plastic particles and high temperature resistance, which is used in the preparation of high temperature plastic particles and antibacterial fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of antibacterial and high temperature resistant plastic particles includes the following steps:

[0033] (1) Raw material pretreatment:

[0034] Put the general-purpose plastic resin in a vacuum drying box for drying treatment, after drying to a moisture content of 0.3%, take out the general-purpose plastic resin for use;

[0035] (2) Ion implantation treatment:

[0036] Place the general plastic resin obtained in step (1) in a MEVVA source high-current ion implanter, use copper ions as the implanted element for ion implantation, and perform copper ion implantation for later use;

[0037] (3) Preparation of modified filler:

[0038] a. Put the hollow microspheres and dysprosium sulfate into a bead mill at a weight ratio of 5:0.4 for grinding, and after grinding at 2000 rpm for 10 minutes, mixed powder A is obtained for use;

[0039] b. Immerse the mixed powder A obtained in operation a in a 0.4% hydrochloric acid solution, and after stirring for 23 minutes at a...

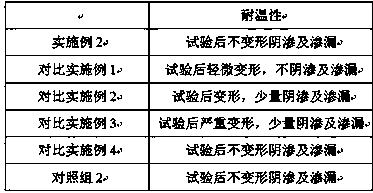

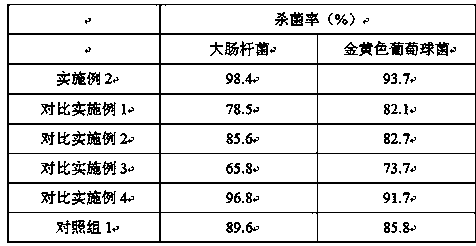

Embodiment 2

[0055] A preparation method of antibacterial and high temperature resistant plastic particles includes the following steps:

[0056] (1) Raw material pretreatment:

[0057] Put the general-purpose plastic resin in a vacuum drying box for drying treatment, after drying to a moisture content of 0.4%, take out the general-purpose plastic resin for use;

[0058] (2) Ion implantation treatment:

[0059] Place the general plastic resin obtained in step (1) in a MEVVA source high-current ion implanter, use copper ions as the implanted element for ion implantation, and perform copper ion implantation for later use;

[0060] (3) Preparation of modified filler:

[0061] a. Put hollow microspheres and dysprosium sulfate into a bead mill at a weight ratio of 5.5:0.5 for grinding, and after grinding at 2500rpm for 13 minutes, mixed powder A is obtained for use;

[0062] b. Immerse the mixed powder A obtained in operation a in a 0.45% hydrochloric acid solution, stir at 245rpm for 25min under the condi...

Embodiment 3

[0078] A preparation method of antibacterial and high temperature resistant plastic particles includes the following steps:

[0079] (1) Raw material pretreatment:

[0080] Put the general-purpose plastic resin in a vacuum drying box for drying treatment, after drying to a moisture content of 0.5%, take out the general-purpose plastic resin for use;

[0081] (2) Ion implantation treatment:

[0082] Place the general plastic resin obtained in step (1) in a MEVVA source high-current ion implanter, use copper ions as the implanted element for ion implantation, and perform copper ion implantation for later use;

[0083] (3) Preparation of modified filler:

[0084] a. Put the hollow microspheres and dysprosium sulfate into a bead mill at a weight ratio of 6:0.6 for grinding, and after grinding at 3000 rpm for 16 minutes, mixed powder A is obtained for use;

[0085] b. Dip the mixed powder A obtained in operation a into a 0.5% hydrochloric acid solution, and after stirring for 27 minutes at 260...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com