Working electrolyte for ultrahigh-voltage aluminium electrolytic capacitor and manufacturing method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of short life, low yield in the aging process, and poor batch stability, and achieve long life, reasonable cost, and high batch stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

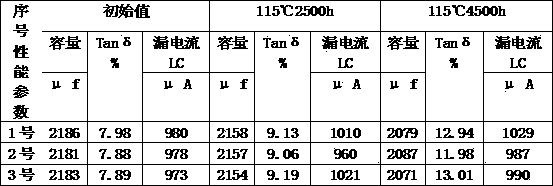

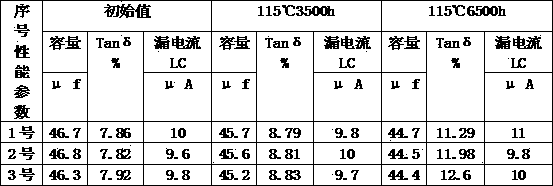

[0024] Example 1: As shown in Table 1, a working electrolyte for ultra-high voltage aluminum electrolytic capacitors is composed of the following raw materials in mass percentage: 68% of the main solvent, 19.9% of the auxiliary solvent, 8% of the solute, modified Additive 4.1%; The weight percentage of each component constitutes No. 1 working electrolyte in Table 1. The main solvents are ethylene glycol and polyglyceryl ether, the auxiliary solvents are tributyl phosphate and polyethylene glycol, and the solutes are dodecyl diacid, azelaic acid and 12-vinyl-8-octadecene dioic acid Ammonium, additives are sorbitol, o-nitroanisole, polyphosphoric acid, liquid ammonia and triethanolamine.

[0025] The specific manufacturing method of No. 1 working electrolyte is: heat ethylene glycol and tributyl phosphate to 110°C, add the main solute, stir and heat up to 115°C, add auxiliary solute and modification additives, and heat up to 130°C. Stir the reaction under heat preservation fo...

Embodiment 2

[0027] Embodiment 2: As shown in Table 1, a kind of working electrolyte for ultra-high voltage aluminum electrolytic capacitor, it is made up of the raw material of following mass percentage: main solvent 75.6%, auxiliary solvent 8%, solute 13%, modified Additive 3.4%; The weight percentage of each component forms No. 2 working electrolyte in Table 1. The main solvent is glycerin, ethylene glycol and diethylene glycol, and the auxiliary solvent is polyalkylene oxide polyol and emulsifier. The solutes are tetradecanedioic acid, lauric acid and 1,6-dodecanedioic acid, and the additives are p-nitrobenzyl alcohol, ammonium hypophosphite, dimethylamine, triethylamine and polyvinyl alcohol.

[0028] The specific manufacturing method of No. 2 working electrolyte is: heating glycerin, ethylene glycol, and diethylene glycol together to 100-110°C, adding polyvinyl alcohol and main solute, stirring and adding auxiliary solute and when the temperature is raised to 115°C Modified additive...

Embodiment 3

[0030] Example 3: As shown in Table 1, a working electrolyte for ultra-high voltage aluminum electrolytic capacitors is composed of the following raw materials in mass percentage: 67% of the main solvent, 11% of the auxiliary solvent, 18% of the solute, modified Additive 4%; the weight percentage of each component forms No. 3 working electrolyte in Table 1. The main solvent is N,N-dimethylformamide, ethylene glycol and diethylene glycol, the auxiliary solvent is polyalkylene oxide polyol, tributyl phosphate and γ-butyrolactone, and the solute is methoxypolyethylene Diol, methyl azelaic acid, 2,7-di-n-butylsuberic acid, lauric acid, 1,6-dodecanedioic acid and mannitol, the additive is cisethylene-1,2-dicarboxylic acid di Methyl esters, maleamide, phosphotungstic acid, and polyethylene glycol phosphate.

[0031] The specific manufacturing method of No. 3 working electrolyte is: the main solvent N,N-dimethylformamide, ethylene glycol and diethylene glycol, the auxiliary solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com