Fiber/metal layer structure composite and preparation method thereof

A composite material and metal layer technology, applied in the field of materials science, can solve the problems of difficulty in manual repair and high maintenance cost, and achieve the effect of improving fatigue performance and increasing damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

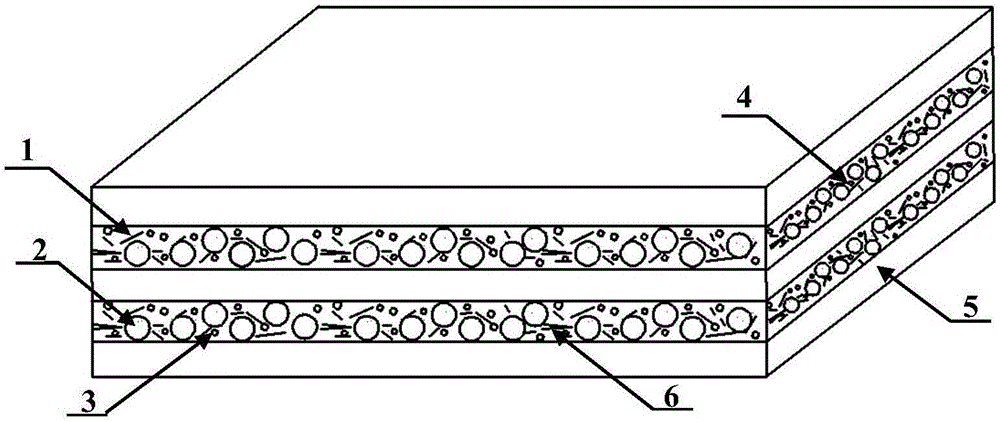

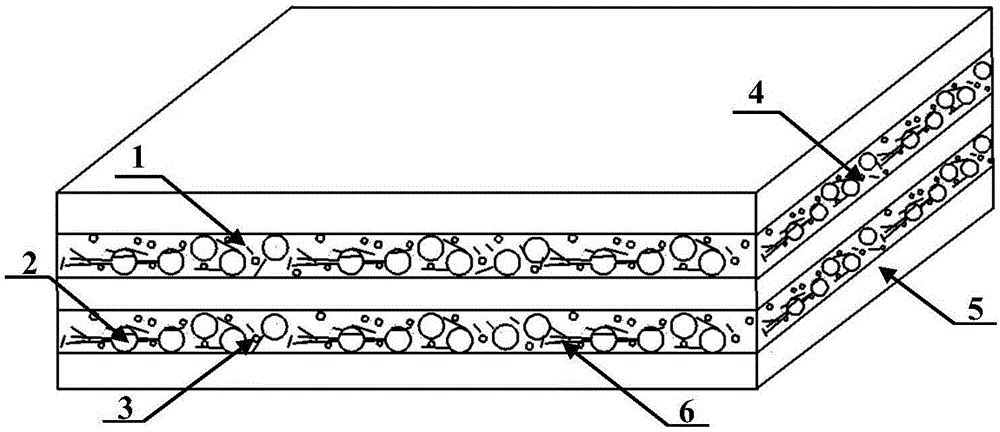

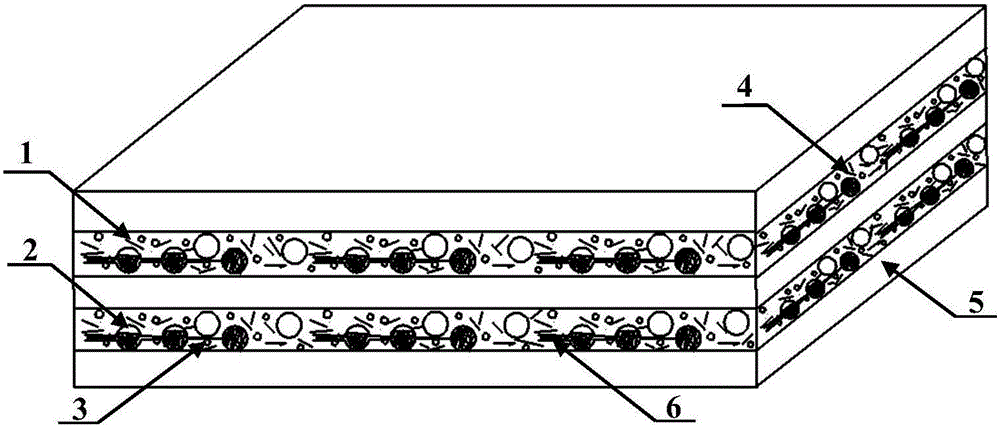

[0036] Such as Figure 1a As shown, the present invention discloses a fiber / metal layer structure composite material, which is composed of fiber resin layer 4 and metal layer 5 alternately; fiber resin layer 4 is short fiber 1 impregnated with resin, and the resin is thermosetting resin or thermoplastic Resin, and in resin, be added with repairing agent microcapsule 2 and catalyst 3, wherein: repairing agent microcapsule 2 internal repair liquid is the urea-formaldehyde resin (DCPD) of cyclopentadiene dimer, and catalyst 3 is 40-50 micron Grubbs catalyst (Grubbs); the material of the metal layer 5 is at least one of aluminum alloy, titanium alloy, aluminum-lithium alloy or magnesium alloy. Such as Figure 1b As shown, when the fiber / metal layer structure composite material of the present invention is subjected to an external force, the crack 6 expands and breaks through the repair agent microcapsule 2; next, as Figure 1c As shown, the punctured repair agent microcapsule 2 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com