Synthetic method for n-butyl isocyanate

A technology of n-butyl isocyanate and synthesis method, which is applied in the direction of carbamate preparation and organic chemistry, etc., can solve problems such as hidden safety hazards, difficulties in transportation and storage processes, and achieve production safety, reasonable process, and high reaction yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of synthetic method of n-butyl isocyanate of the present embodiment is characterized in that, comprises the steps:

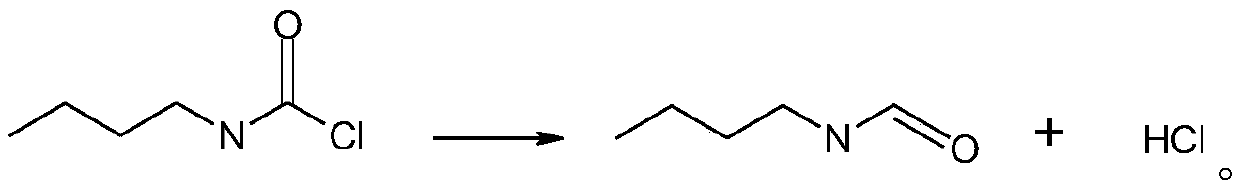

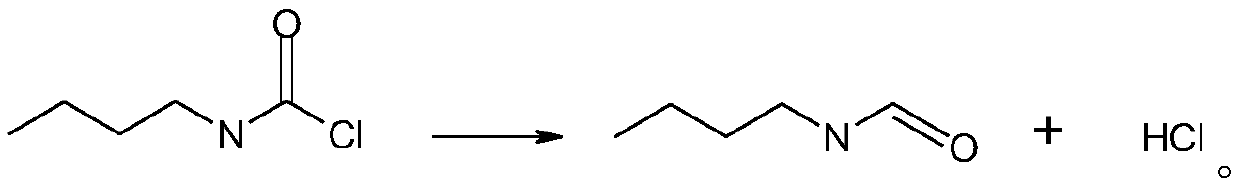

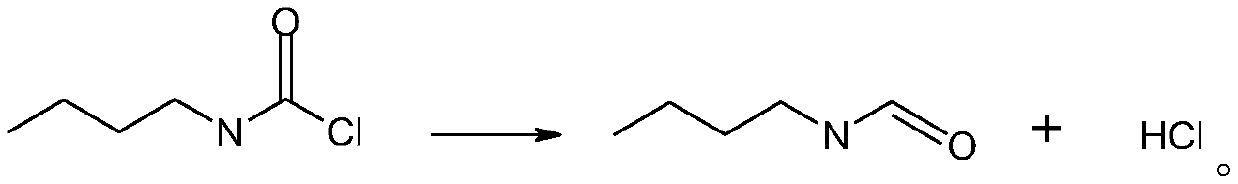

[0022] Select n-butylcarbamoyl chloride, in an organic solvent, under the catalysis of a catalyst, react at a temperature of 80-160°C for 8-15h, and obtain n-butyl isocyanate through thermal decomposition. The reaction equation is:

[0023]

[0024] Wherein, the catalyst is triethylamine, pyridine, N-methylpyrrole or N-methylpyridine.

[0025] Wherein, the organic solvent is any one of toluene, xylene, n-hexane, methylene chloride, chloroform, ethylene dichloride, chlorobenzene and dichlorobenzene.

[0026] Wherein, the molar ratio of the n-butylcarbamoyl chloride to the catalyst is 1:0.05-0.1.

[0027] Wherein, the molar ratio of the n-butylcarbamoyl chloride to the catalyst is 1:0.05.

[0028] Wherein, the molar ratio of the amount of the organic solvent to the added amount of n-butylcarbamoyl chloride is 3-20:1.

Embodiment 1

[0031] In a 1000ml four-neck flask equipped with mechanical stirring, a constant pressure dropping funnel, a reflux condenser and a thermometer, add 200g of n-butylcarbamoyl chloride, 10g of triethylamine and 700g of toluene, start stirring, and heat up under reflux. , stirred and reacted for 10 h, after the reaction was finished, 138.8 g of n-butyl isocyanate was distilled out, the yield was 95%, and the content was above 99% (GC).

Embodiment 2

[0033] In a 1000ml four-neck flask equipped with mechanical stirring, a constant pressure dropping funnel, a reflux condenser and a thermometer, add 1mol of n-butylcarbamoyl chloride, 0.1mol of N-methylpyrrole and 3mol of chlorobenzene, and start stirring , heating up, stirring and reacting at a temperature of about 90° C. for 15 hours, after the reaction was completed, 91 g of n-butyl isocyanate was distilled out, the yield was 92%, and the content was above 99% (GC).

[0034] The invention has an advanced process route, avoids highly toxic phosgene and diphosgene, has simple and safe operation, high reaction yield, low production cost, less three wastes, and has great implementation value and social and economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com