Device and method for applying group frequency ultrasounds to conduct magnesium alloy semi-continuous casting

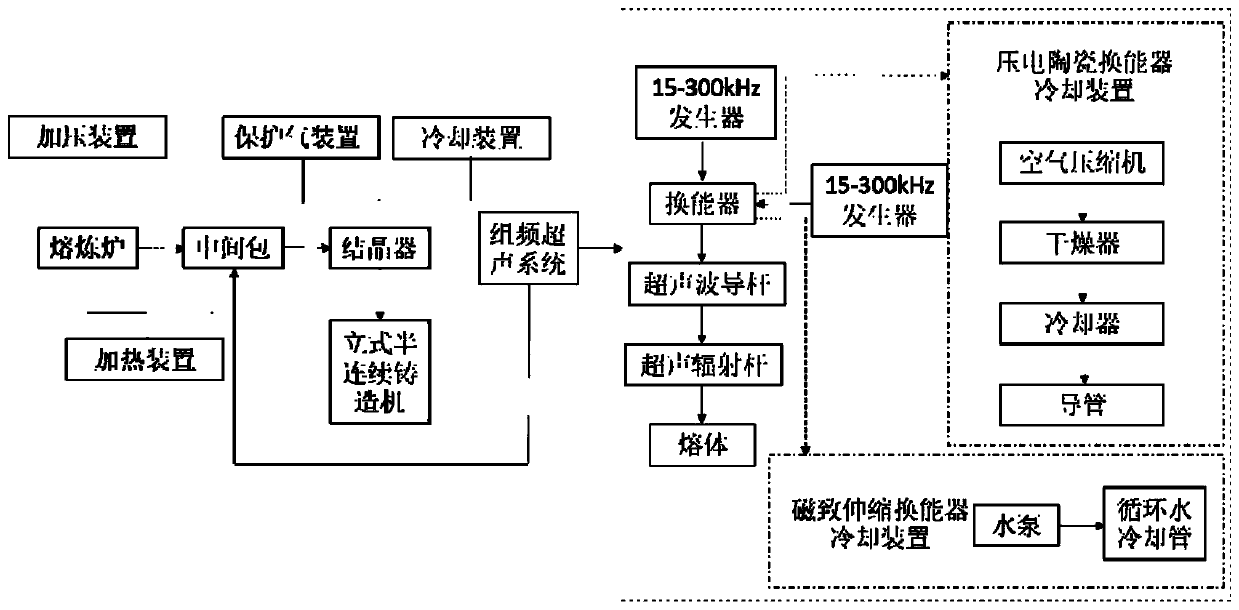

A magnesium alloy, semi-continuous technology, applied in the direction of casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of limited sound wave superposition effect, low stirring intensity, attenuation, etc., and achieve the effect of enhancing the range of cavitation and reducing heat Effect of loss and improvement of cavitation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

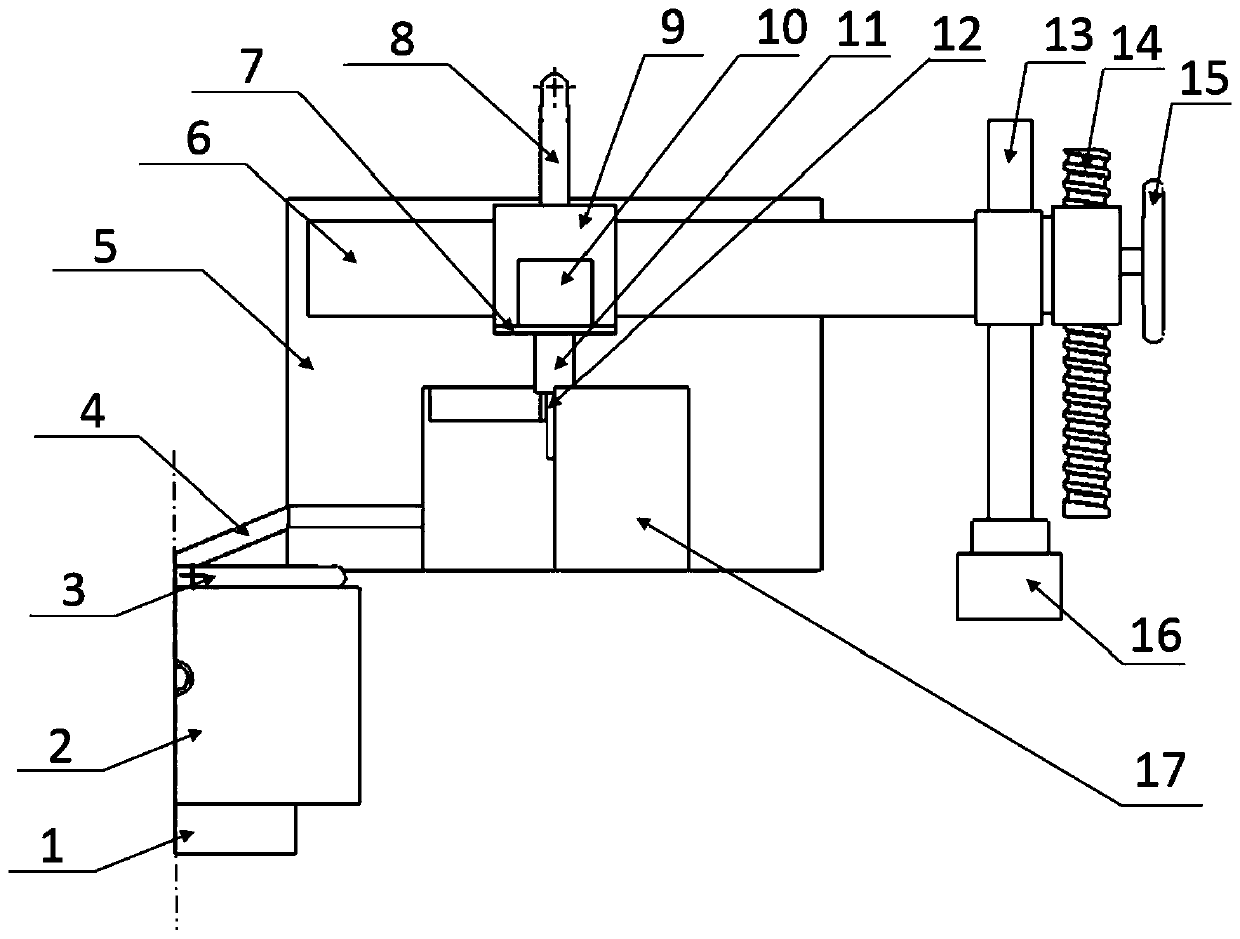

[0071] The structure of the device for semi-continuous casting of magnesium alloys by applying group frequency ultrasound is as follows: figure 2 Shown, comprise smelting furnace 5, tundish 17 and crystallizer 2, be provided with pipette 8 between smelting furnace 5 and tundish 17, be provided with chute 4 between tundish 17 and crystallizer 2; A protective gas annular pipe 3 is provided, and the inside of the protective gas annular pipe 3 communicates with the protective gas source through a pipeline. The protective gas annular pipe 3 is provided with an air outlet, and the air outlet faces the axis of the crystallizer;

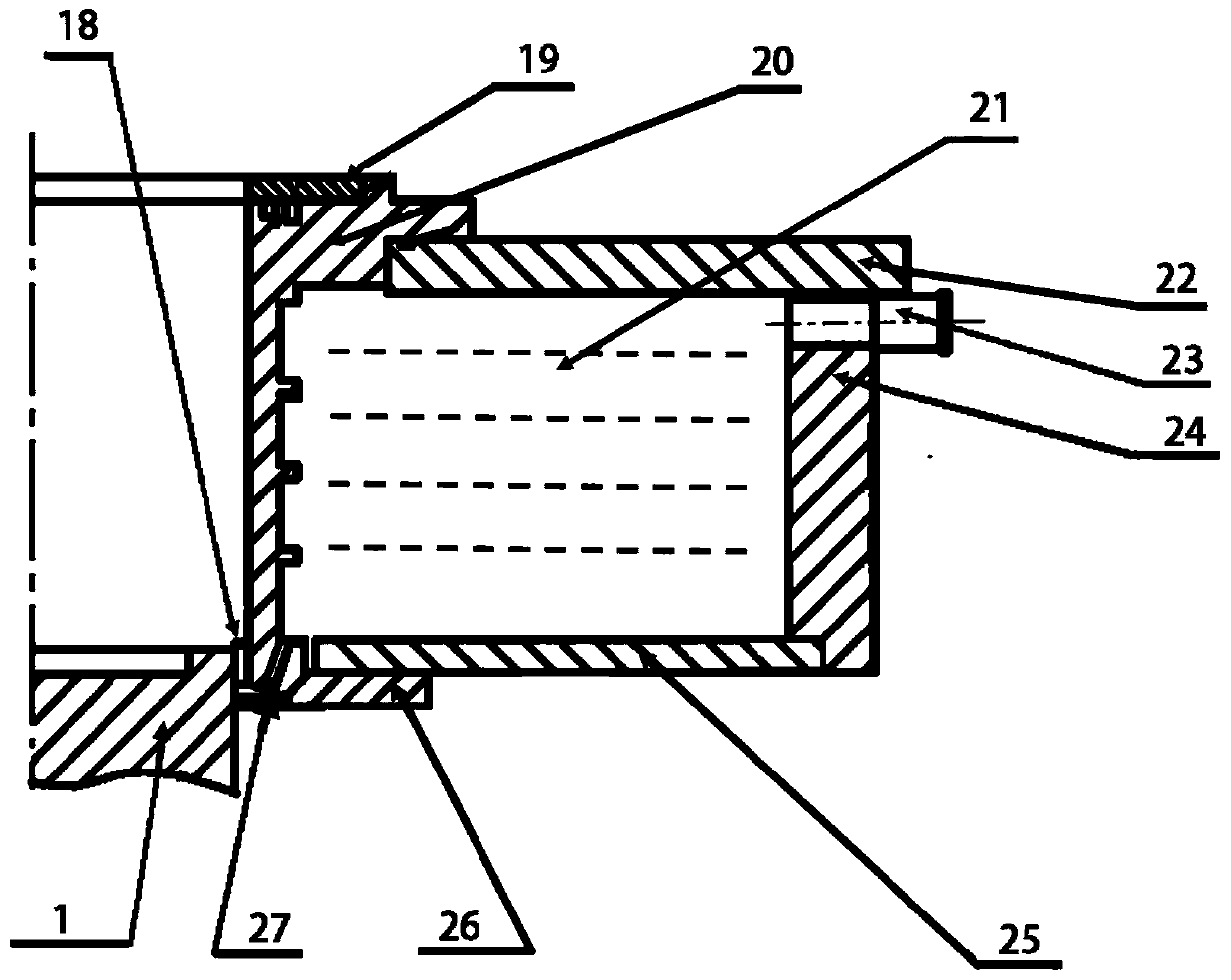

[0072] The tundish structure is as Figure 4 As shown, a first ultrasonic generating device is fixed on the side wall, and a second ultrasonic generating device is arranged in the tundish. The first ultrasonic generating device consists of a first ultrasonic radiation rod 31, a first ultrasonic guide rod 32 and a first ultrasonic transducer The second ultr...

Embodiment 2

[0095] Apply group frequency ultrasonic to carry out the device structure of semi-continuous casting of magnesium alloy with embodiment 1, difference is:

[0096] (1) Tundish structure such as Figure 5 As shown, the first ultrasonic generating device is fixed on the bottom plate;

[0097] (2) The axes of the first ultrasonic radiation rod 31 and the second ultrasonic radiation rod 12 coincide;

[0098] (3) The ultrasonic transducer is a piezoelectric ceramic transducer with a structure such as Figure 7 Shown in (b); piezoelectric ceramic transducer comprises piezoelectric ceramic transducer casing 44, two metal diaphragms 47 and titanic acid piezoelectric ceramic material 48, and piezoelectric ceramic transducer casing 44 is provided with The transducer air inlet 43 and the transducer air outlet 49 are used to circulate the cooling gas. The upper and lower ends of the titanic acid piezoelectric ceramic material 48 are respectively connected to a metal diaphragm 47, and the...

Embodiment 3

[0110] Apply group frequency ultrasonic to carry out the device structure of semi-continuous casting of magnesium alloy with embodiment 1, difference is:

[0111] Ultrasonic transducer structure such as Figure 8 As shown in (a), two sets of terbium iron magnetostrictive materials are arranged in each transducer box;

[0112] Method is with embodiment 1, and difference is:

[0113] (1) Preparation Magnesium alloy ingot;

[0114] (2) After refining, the temperature of the magnesium alloy melt is 50°C above the liquidus line of the magnesium alloy;

[0115] (3) The tundish, pipette, first ultrasonic radiation rod and second ultrasonic radiation rod are preheated to the same temperature as the magnesium alloy melt; the vertical distance between the first ultrasonic radiation rod and the second ultrasonic radiation rod is 50mm

[0116] (4) The frequencies of ultrasonic waves emitted by the two ultrasonic radiation rods are 20 kHz and 35 kHz respectively; the bottom end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com