Porcelain ceramic particle water scalpel sand and preparation method thereof

A technology of ceramic particles and porcelain, which is applied in the field of ceramic tiles, can solve problems such as non-compliance with environmental and resource protection policies, achieve a reasonable balance between economic benefits and environmental protection, sustainable development, wide application range, good cutting accuracy and cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

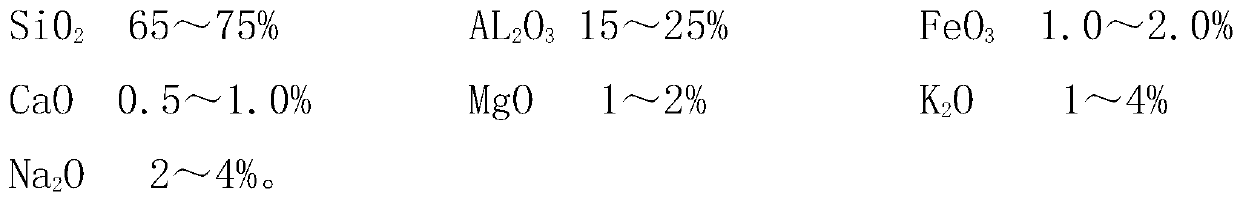

[0025] The porcelain ceramic particle waterjet sand consists of the following components in parts by weight:

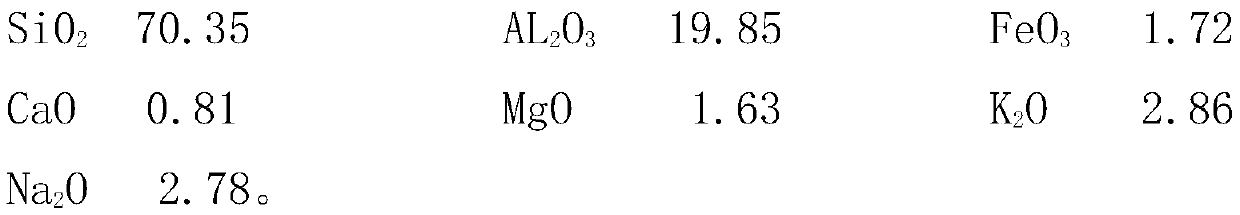

[0026] Si0 2 70.35 AL 2 o 3 19.85 FeO 3 1.72

[0027] CaO 0.81 MgO 1.63 K 2 O 2.86

[0028] Na 2 O 2.78.

[0029] The preparation method of the porcelain ceramic particle waterjet sand comprises the following steps:

[0030] ⑴Preparation: According to the formula of the green body, add mud, sand and auxiliary material additives in a certain proportion to the ball mill to prepare the mud, then spray the powder through the spray drying tower, press it through a 35000MPa press, dry it, and finally send it to the roller kiln for drying Firing, the firing temperature is 1100-1200°C, and the firing time is 50-70min.

[0031] ⑵ Crushing: The three-stage crusher is used to crush the porcelain ceramic tiles. The crushing process is divided into three stages: coarse crushing, medium crushing and fine crushing. The diameter control range of porcelain ceramic tiles wh...

Embodiment example 2

[0037] The porcelain ceramic particle waterjet sand consists of the following components in parts by weight:

[0038] Si0 2 70.35 AL 2 o 3 19.85 FeO 3 1.72

[0039] CaO 0.81 MgO 1.63 K 2 O 2.86

[0040] Na 2 O 2.78.

[0041] The preparation method of the porcelain ceramic particle waterjet sand comprises the following steps:

[0042] ⑴Preparation: According to the formula of the green body, add mud, sand and auxiliary material additives in a certain proportion to the ball mill to prepare the mud, then spray the powder through the spray drying tower, press it through a 35000MPa press, dry it, and finally send it to the roller kiln for drying Firing, the firing temperature is 1100-1200°C, and the firing time is 50-70min.

[0043] ⑵ Crushing: The three-stage crusher is used to crush the porcelain ceramic tiles. The crushing process is divided into three stages: coarse crushing, medium crushing and fine crushing. The diameter control range of porcelain ceramic tiles when...

Embodiment example 3

[0049] The porcelain ceramic particle waterjet sand consists of the following components in parts by weight:

[0050] Si0 2 70.35 AL 2 o 3 19.85 FeO 3 1.72

[0051] CaO 0.81 MgO 1.63 K 2 O 2.86

[0052] Na 2 O 2.78.

[0053] The preparation method of the porcelain ceramic particle waterjet sand comprises the following steps:

[0054] ⑴Preparation: According to the formula of the green body, add mud, sand and auxiliary material additives in a certain proportion to the ball mill to prepare the mud, then spray the powder through the spray drying tower, press it through a 35000MPa press, dry it, and finally send it to the roller kiln for drying Firing, the firing temperature is 1100-1200°C, and the firing time is 50-70min.

[0055] ⑵ Crushing: The three-stage crusher is used to crush the porcelain ceramic tiles. The crushing process is divided into three stages: coarse crushing, medium crushing and fine crushing. The diameter control range of porcelain ceramic tiles wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com