Preparation method of rare earth element-doped PMN-PT relaxor ferroelectric powder

A technology of PMN-PT and rare earth elements, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve problems such as uneven composition, achieve uniform composition, simple process steps, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

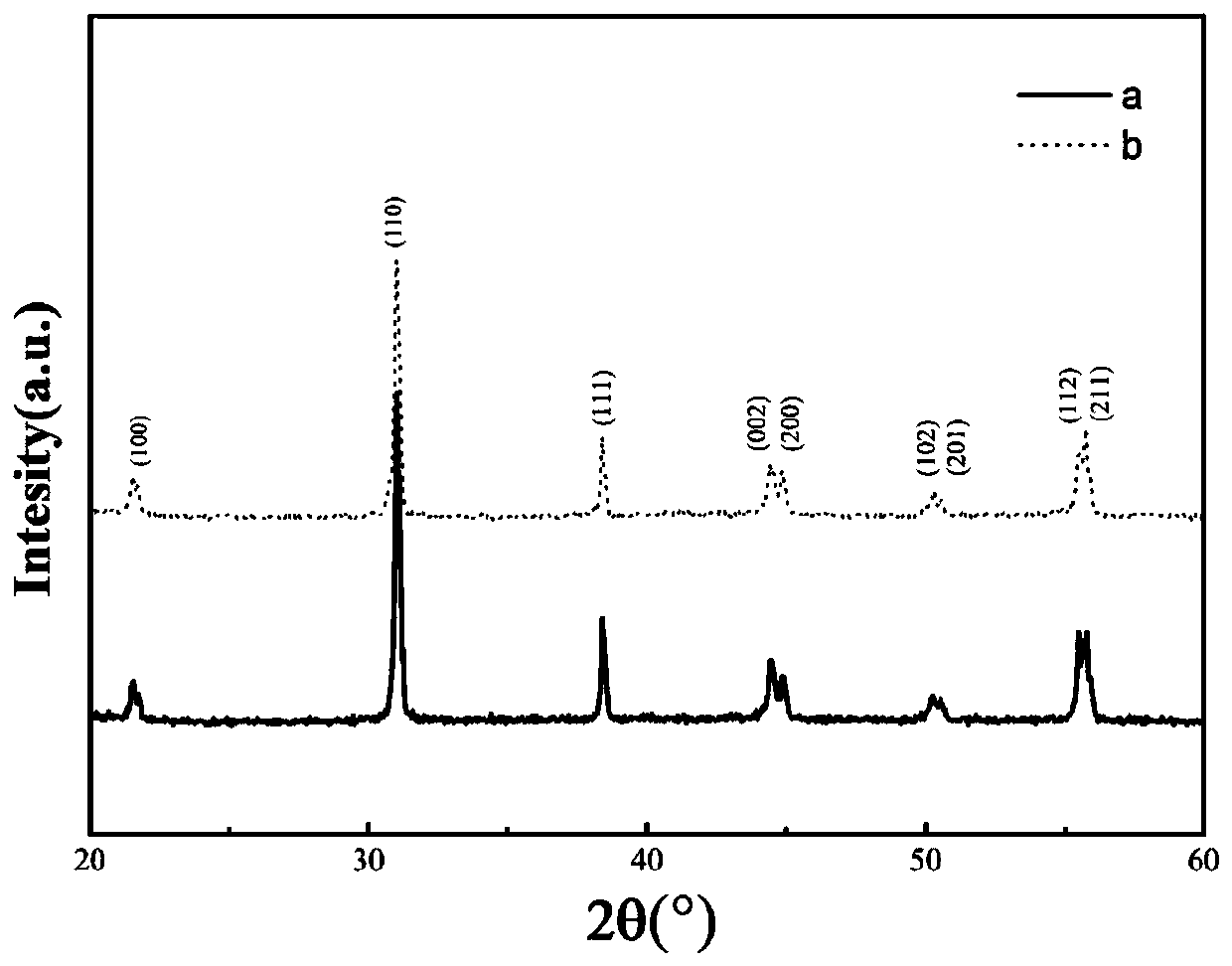

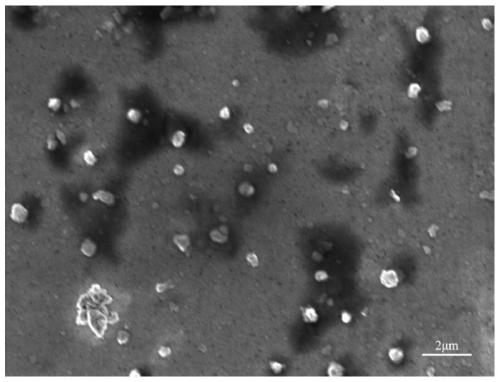

[0027] Example 1: Preparation of 0.025La-PMN-0.29PT powder

[0028] (1) First, PbO (99.9%), La 2 o 3 (99.99%), MgO (99.99%), H 5 Nb 3 o 10 (99.0%), C 16 h 36 o 4 Ti (98.5%) is weighed according to the stoichiometric ratio, calculated with the general chemical formula of 0.025La-PMN-0.29PT, and the above raw materials are all produced by Aladdin (aladdin) company;

[0029] (2) configuration of niobium citrate solution; according to the molar ratio Nb:C 2 h 2 o 4 2H 2 O=1:4 Weigh H 5 Nb 3 o 10 and C 2 h 2 o 4 2H 2 O in a beaker, add an appropriate amount of distilled water, heat and dissolve on a constant temperature magnetic stirrer at 80°C, cool to room temperature after clarification, then add ammonia water, adjust the pH to ≥ 10, and obtain a white precipitate, filter the precipitate suspension to obtain a white of fresh Nb(OH) 5 , according to the molar ratio Nb:C 6 h 8 o 7 ·H 2O=1:4 Weigh citric acid, add to the obtained Nb(OH) 5 Add an appropriate ...

Embodiment 2

[0036] Example 2: Preparation of 0.015Sm-PMN-0.29PT powder

[0037] (1) First, PbO (99.9%), Sm 2 o 3 (99.99%), MgO (99.99%), H 5 Nb 3 o 10 (99.0%), C 16 h 36 o 4 Ti (98.5%) is weighed according to the stoichiometric ratio, and the specific chemical formula is 0.015Sm-PMN-0.29PT, and the above raw materials are all produced by Aladdin Company;

[0038] (2) configuration of niobium citrate solution; according to the molar ratio Nb:C 2 h 2 o 4 2H 2 O=1:4 Weigh H 5 Nb 3 o 10 and C 2 h 2 o 4 2H 2 O in a beaker, add an appropriate amount of distilled water, heat and dissolve on a constant temperature magnetic stirrer at 80°C, cool to room temperature after clarification, then add ammonia water, adjust the pH to ≥ 10, and obtain a white precipitate, filter the precipitate suspension to obtain a white of fresh Nb(OH) 5 , according to the molar ratio Nb:C 6 h 8 o 7 ·H 2 O=1:4 Weigh citric acid, add to the obtained Nb(OH) 5 Add an appropriate amount of distilled ...

Embodiment 3

[0045] Example 3: Preparation of 0.025Pr-PMN-0.29PT powder

[0046] (1) First, PbO (99.9%), Pr 2 o 3 (99.9%), MgO (99.99%), H 5 Nb 3 o 10 (99.0%), C 16 h 36 o 4 Ti (98.5%) is weighed according to the stoichiometric ratio, and the specific chemical general formula is calculated as 0.015Pr-PMN-0.29T, and the above raw materials are all produced by Aladdin Company;

[0047] (2) configuration of niobium citrate solution; according to the molar ratio Nb:C 2 h 2 o 4 2H 2 O=1:4 Weigh H 5 Nb 3 o 10 and C 2 h 2 o 4 2H 2 O in a beaker, add an appropriate amount of distilled water, heat and dissolve on a constant temperature magnetic stirrer at 80°C, cool to room temperature after clarification, then add ammonia water, adjust the pH to ≥ 10, and obtain a white precipitate, filter the precipitate suspension to obtain a white of fresh Nb(OH) 5 , according to the molar ratio Nb:C 6 h 8 o 7 ·H 2 O=1:4 Weigh citric acid, add to the obtained Nb(OH) 5 Add an appropriate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com